Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Toro 74413

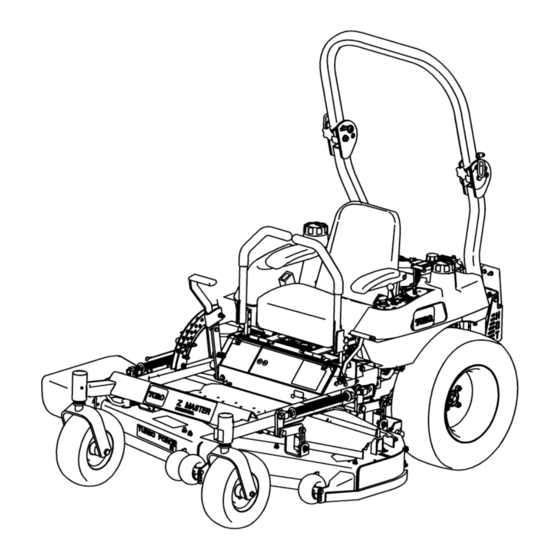

- Page 1 Form No. 3351-704 Z449 Z Master With 48 in or 52in TURBO FORCE Side Discharge Mower Model No. 74413—Serial No. 250000001 and Up Model No. 74415—Serial No. 250000001 and Up Operator’s Manual Original Instructions (EN) Register your product at www.Toro.com...

-

Page 2: Table Of Contents

......Using the Rollover Protection System (ROPS) . . . The Toro Total Coverage Guarantee ....Think Safety First . -

Page 3: Introduction

Authorized Service instruction may result in personal injury or death. Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 illustrates This product is capable of amputating hands and feet and the location of the model and serial numbers on the throwing objects. - Page 4 Inspect the area where the equipment is to be used and Do not operate the mower under the influence of remove all objects such as rocks, toys and wire which alcohol or drugs. can be thrown by the machine. Use extreme care when loading or unloading the Use extra care when handling gasoline and other fuels.

- Page 5 (ROPS) decals. Keep the roll bar in the raised and locked position and Use only Toro-approved attachments. Warranty may be use the seat belt when operating the machine. voided if used with unapproved attachments. Be certain that the seat belt can be released quickly in the event of an emergency.

-

Page 7: Slope Chart

Slope Chart Align this edge with a vertical surface (Tree, Building, Fence post, pole, etc.) -

Page 9: Safety And Instruction Decals

Safety and Instruction Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. 58-6520 1. Grease 1-523552 65-2690 1-633818 66-1340 43-8480 68-8340 54-9220... - Page 10 98-5954 98-4387 1. Warning—wear hearing protection. 103-1997 107-1613 103–2644 104-8569 107-1622 105-7798...

- Page 11 107-1687 107-1688 107-2100 107-2102...

- Page 12 107-2112 107-2148 107-9309 1. Warning—read the Operator’s Manual for information on charging the battery; contains lead; do not discard. 2. Read the Operator’s Manual.

- Page 13 Battery Symbols Some or all of these symbols are on your battery. 1. Explosion hazard 7. Wear eye protection; explosive gases can 2. No fire, open flames, or cause blindness and smoking. other injuries 3. Caustic liquid/chemical 8. Battery acid can cause burn hazard blindness or severe 4.

-

Page 14: Gasoline And Oil

Gasoline and Oil Warning Recommended Gasoline Gasoline is harmful or fatal if swallowed. Long-term exposure to vapors can cause serious Use unleaded regular gasoline suitable for automotive use injury and illness. (85 pump octane minimum). You may use leaded regular gasoline if unleaded regular is not available. -

Page 15: Operation

Operation 1. To lower the roll bar, loosen the front handles (Fig. 2). Note: Determine the left and right sides of the machine from the normal operating position. Using the Rollover Protection System (ROPS) m-7406 Figure 2 Warning 1. Front handle To avoid injury or death from a rollover, keep the 2. -

Page 16: Think Safety First

3. Lower the the roll bar to the down position. Think Safety First Note: There are 2 down positions. See Figure 4 for the Read all safety instructions and symbols in the safety positions. section. Knowing this information could help you or bystanders avoid injury. -

Page 17: Controls

Toro recommends that you use protective equipment for Using the Hour Meter your eyes, ears, feet, and head. The hour meter (Fig. 8) records the number of hours the engine has operated. It operates when the engine is running. Caution Use these times for scheduling regular maintenance. -

Page 18: Operating The Parking Brake

Operating the Parking Brake 3. Move the PTO (power takeoff) to Off (Fig. 11). Always set the parking brake when you stop the machine or leave it unattended. Important Do not park the machine on slopes unless the wheels are chocked or blocked. Setting the Parking Brake 1. -

Page 19: Operating The Power Takeoff (Pto)

Stopping the Engine 3. Pull out the power takeoff (PTO) switch to engage the PTO (Fig. 15). 1. Push the PTO to Off (Fig. 13). 2. Move the throttle lever midway between Slow and Fast (Fig. 13). 3. Let the engine idle for 60 seconds (Fig. 14). 4. -

Page 20: Driving Forward Or Backward

Testing the Safety Interlock System 3. To go forward, slowly push the motion control levers forward (Fig. 16). Test the safety interlock system before you use the machine each time. If the safety system does not operate as described below, have an Authorized Service Dealer repair it immediately. -

Page 21: Adjusting The Height-Of-Cut

Adjusting the Anti-scalp Caution Rollers Children or bystanders may be injured if they Whenever you change the height-of-cut, adjust the height move or attempt to operate the machine while it is of the anti-scalp rollers. unattended. Always remove the ignition key and set the Adjusting the Outer Roller parking brake when leaving the machine 1. -

Page 22: Positioning The Seat

Adjusting the Center Rollers Positioning the Seat 1. Disengage the PTO, move the motion control levers to The seat can move forward and backward. Position the seat the neutral locked position, and set the parking brake. where you have the best control of the machine and are most comfortable. -

Page 23: Operating With The Side Discharge

Changing to Machine Operation Warning Turn the bypass valves in to operate (Fig. 21). Note: Do not overtighten the bypass valves. Driving on a street or roadway without turn signals, lights, reflective markings, or a slow Note: The machine will not drive unless the bypass valves moving vehicle emblem is dangerous and can lead are turned in. -

Page 24: Tips For Mowing Grass

File down or it is late fall when grass grows more slowly. any nicks and sharpen the blades as necessary. If a blade is damaged or worn, replace it immediately with a genuine Toro replacement blade. -

Page 25: Maintenance

Maintenance Note: Determine the left and right sides of the machine from the normal operating position. Recommended Maintenance Schedule Maintenance Service Maintenance Procedure Interval Check the hydraulic fluid level. After First 8 Hours Change the engine oil. Change the hydraulic filter. Check the engine oil level. -

Page 26: Servicing The Cutting Blades

Check the cutter blades daily for sharpness, and for any wear or damage. File down any nicks and sharpen the blades as necessary. If a blade is damaged or worn, replace it immediately with a genuine Toro replacement blade. For convenient sharpening and replacement, keep extra blades on hand. - Page 27 (Fig. 24). Measure from a level surface to the or is bent. To ensure optimum performance and continued cutting edge of the blades (Fig. 25). Note this safety conformance of the machine, use genuine Toro dimension. replacement blades. Using replacement blades made by...

-

Page 28: Cleaning The Cooling System

1. Use a file to sharpen the cutting edge at both ends of the 3. Remove the air intake screen, recoil starter, and fan blade at the original angle (Fig. 27). housing (Fig. 29). m–1854 Figure 27 1. Sharpen at original angle Note: The blade retains its balance if the same amount of material is removed from both cutting edges. -

Page 29: Servicing The Engine Oil

3. Clean around the air cleaner to prevent dirt from getting 3. Replace the paper element if it is damaged, or cannot be into the engine and causing damage (Fig. 30). cleaned thoroughly. Installing the Foam and Paper Elements Important To prevent engine damage, always operate the engine with the complete foam and paper air cleaner assembly installed. - Page 30 4. Clean around the oil dipstick (Fig. 31) so that dirt 7. Rotate oil drain valve to allow oil to drain (Fig. 32). cannot fall into the filler hole and damage the engine. Figure 32 m–7449 1. Oil drain valve 2.

-

Page 31: Servicing The Spark Plug(S)

3. Apply a thin coat of new oil to the rubber gasket on the Checking the Spark Plug(s) replacement filter (Fig. 33). 1. Look at the center of the spark plug(s) (Fig. 35). If you 4. Install the replacement oil filter to the filter adapter, see light brown or gray on the insulator, the engine is turn the oil filter clockwise until the rubber gasket operating properly. -

Page 32: Draining The Fuel Tank

4. Stop the engine, remove the key, and wait for all 5. Disconnect the fuel line from the fuel filter (Fig. 36). moving parts to stop before leaving the operating 6. Open the fuel shutoff valve (Fig. 36). position. Note: Allow gasoline to drain into a fuel container can 5. -

Page 33: Checking The Tire Pressure

5. Wipe up any excess grease. 4. Grease the idler pulley pivot (Fig. 38). 5. Grease the fittings on the push arms (Fig. 38). Where to Add Grease Where to Add Light Oil or Spray Lubricate the grease fittings as shown on the Check Lubrication Service Reference Aid decal (Fig. - Page 34 Note: There are 2 ways of checking the hydraulic oil. One Warning is for warm oil and the other for cold oil. The baffle inside the tank has 2 levels depending on whether the oil is warm or cold. Hydraulic fluid escaping under pressure can penetrate skin and cause injury.

-

Page 35: Waste Disposal

4. Apply a thin coat hydro fluid to the rubber gasket on the 5. Check hydraulic fluid level and add fluid as required to replacement filter (Fig. 42). maintain the proper level. 6. Repeat this procedure on the opposite wheel. Warning Hydraulic fluid escaping under pressure can penetrate skin and cause injury. -

Page 36: Setting The Hydraulic Pump Neutral Position

3. Tilt the seat forward. 7. Check where the control lever is relative to the notch in the console (Fig. 43). It should be centered, allowing 4. Begin with either the left or right motion control lever. the lever to pivot outward to the neutral lock position. 5. -

Page 37: Adjusting The Tracking

Setting the Left-hand Hydraulic Pump 3. Adjust the pump rod length by rotating the double nuts on the rod in the appropriate direction until the wheel is Neutral Position still or slightly creeps in reverse (Fig. 44). 1. Start the engine, open the throttle halfway and release 4. -

Page 38: Adjusting The Caster Pivot Bearing

4. To make the machine move to the right, turn the knob 4. Tighten the locknut until the spring washers are flat, toward the right side of the machine; refer to Figure 46. then back off 1/4 turn to properly set the pre-load on the bearings (Fig. -

Page 39: Leveling The Mower At Three Positions

Leveling the Mower at Three Positions Important There are only 3 measuring positions needed to level the mower. MEASURE FROM CUTTING EDGE TO A LEVEL SURFACE m–2539 Setting Up the Machine Figure 50 1. Position mower on a flat surface. 2. - Page 40 Adjusting the Front-to-Rear Mower Pitch 7. Loosen the front swivel jam nuts, at the front of the right and left swivels, approximately 1/2 inch (13 mm) 1. Position the right blade front to rear (Fig. 52). (Fig. 54). m–1078 Figure 52 2.

-

Page 41: Adjusting The Push Arms

Adjusting the Push Arms Inspecting the Belts If needed, adjust the push arms to increase or decrease the Inspect all belts every 250 hours. mower belt tension. Check belts for cracks, frayed edges, burn marks, or any 1. Loosen the jam nut and rotate the ball joint other damage. -

Page 42: Replacing The Pump Drive Belt

7. Insert a ratchet with a short extension or a breaker bar Replacing the Pump Drive Belt into the square hole in the fixed idler arm (Fig. 57). Check the pump drive belt for wear after every 50 operating hours. 1. -

Page 43: Adjusting The Parking Brake

Adjusting the Parking Brake Servicing the Fuses Check the parking brake for proper adjustment. Service Interval/Specification 1. Disengage the brake lever (lever down). The electrical system is protected by fuses. It requires no maintenance; however, if a fuse blows, check the 2. - Page 44 Checking the Electrolyte Level Installing the Battery 1. Shut off the engine and wait for all moving parts to 1. Position the battery in the tray with the terminal posts stop. toward the engine (Fig. 62). 2. Open the hood. 3.

- Page 45 Removing the Battery Adding Water to the Battery The best time to add distilled water to the battery is just Warning before you operate the machine. This lets the water mix thoroughly with the electrolyte solution. The battery terminals or metal tools could short Note: Never fill the battery with distilled water while the against metal machine components, causing battery installed in the machine.

-

Page 46: Replacing The Grass Deflector

4. When the battery is fully charged, unplug the charger 1. Remove the locknut, bolt, spring, and spacer that hold from the electrical outlet, then disconnect the charger the deflector to the pivot brackets (Fig. 64). leads from the battery posts (Fig. 63). m–7708 m–4970 Figure 63... -

Page 47: Wiring Diagram

Wiring Diagram... -

Page 48: Cleaning And Storage

Cleaning and Storage A. Add a petroleum based stabilizer/conditioner to fuel in the tank. Follow mixing instructions from stabilizer manufacture. Do not use an alcohol 1. Disengage the power takeoff (PTO), set the parking based stabilizer (ethanol or methanol). brake and turn the ignition key to off. Remove spark plug wire. -

Page 49: Troubleshooting

Troubleshooting Problem Possible Causes Corrective Action Starter does not crank. 1. Blade control (PTO) is 1. Move blade control (PTO) to engaged. Disengaged. 2. Parking brake is not on. 2. Set parking brake. 3. Operator is not seated. 3. Sit on the seat. 4. - Page 50 Problem Possible Causes Corrective Action Machine does not drive. 1. Traction belt is worn, loose or 1. Contact Authorized Service broken. Dealer. 2. Traction belt is off pulley. 2. Contact Authorized Service Dealer. 3. Hydro fluid level low. 3. Add hydro fluid to reservoir. Abnormal vibration.

-

Page 52: The Toro Total Coverage Guarantee

If for any reason you are dissatisfied with your Distributor’s service or have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.