Toro TimeCutter SS 4200 Operator's Manual

Hide thumbs

Also See for TimeCutter SS 4200:

- Operator's manual (48 pages) ,

- Operator's manual (48 pages) ,

- Operator's manual (52 pages)

Table of Contents

Summary of Contents for Toro TimeCutter SS 4200

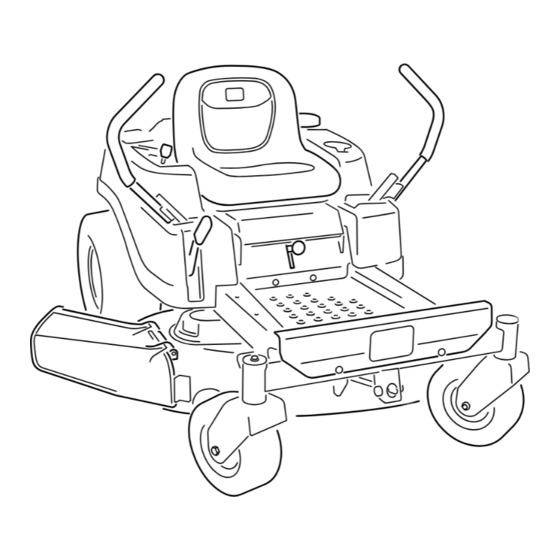

- Page 1 Form No. 3371-741 Rev A TimeCutter ® SS 4200 Riding Mower Model No. 74623—Serial No. 312000001 and Up G017534 To register your product or download an Operator's Manual or Parts Catalog at no charge, go to www.Toro.com. Original Instructions (EN)

-

Page 2: Introduction

Figure 1 accessories may alter the warranty, traction, and Under the seat safety of the machine. Failure to use original Toro parts could cause serious injury or death. Making 1. Model and serial number plate unauthorized changes to the engine, fuel or venting system, may violate EPA and CARB regulations. -

Page 3: Table Of Contents

Cleaning and Storage .......... 41 Troubleshooting............43 Introduction..............2 Schematics ..............45 Safety ................4 Safe Operating Practices ........4 Toro Riding Mower Safety ........6 Slope Indicator............. 7 Safety and Instructional Decals ......8 Product Overview ............11 Controls ............. 12 Operation..............13 Think Safety First .......... -

Page 4: Safety

• Always wear eye protection when operating the information in addition to the instructions found in mower. the ANSI standard below can be found in Toro Riding Mower Safety at the end of this section. • Data indicates that operators, age 60 years and... - Page 5 A hitch kit is available for this machine and can be • Remove or mark obstacles such as rocks, tree limbs, obtained by contacting an Authorized Toro Dealer. etc. from the mowing area. Tall grass can hide Do not tow without first installing this manufacturer obstacles.

-

Page 6: Toro Riding Mower Safety

• Maintain or replace safety and instruction decals as necessary. • Use only genuine Toro replacement parts to ensure that original standards are maintained. Toro Riding Mower Safety The following list contains safety information specific to Toro products or other safety information that you must know that may not be included in the ANSI standards. -

Page 7: Slope Indicator

Slope Indicator G011841 Figure 3 This page may be copied for personal use. 1. The maximum slope you can safely operate the machine on is 15 degrees. Use the slope chart to determine the degree of slope of hills before operating. Do not operate this machine on a slope greater than 15 degrees. Fold along the appropriate line to match the recommended slope. -

Page 8: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or lost. 93-7009 1. Warning—don't operate the mower with the deflector up or removed;... - Page 9 119-8815 1. Parking position 4. Neutral 2. Fast 5. Reverse 3. Slow 121-2989 1. Bypass lever position for 2. Bypass lever position for pushing the machine operating the machine Manufacturer's Mark 1. Indicates the blade is identified as a part from the original machine manufacturer.

- Page 10 119-8874 1. Low speed 2. High speed 120-2239 1. Warning—read the Operator's Manual. 5. Warning—do not use split ramps, use a full ramps when transporting machine. 2. Warning—read the instructions before servicing or performing 6. Loss of traction/control hazard, slopes—loss of traction/control maintenance;...

-

Page 11: Product Overview

121-0771 1. Choke 4. Slow 2. Fast 5. Power take-off (PTO), Blade control switch 3. Continuous variable setting Product Overview G014526 Figure 4 1. Deflector 4. Height of cut lever 7. Footrest 10. Engine 2. Rear drive wheel 8. Fuel tank cap 11. -

Page 12: Controls

Controls lever is moved. Move the control levers outward from the center to the park position and exit the machine Become familiar with all of the controls inFigure 4, and (Figure 16). Always position the motion control levers Figure 5 before you start the engine and operate the into the park position when you stop the machine or machine. -

Page 13: Operation

Operation operator it is lowered toward the ground. Only adjust the height of cut while machine is not moving (Figure 20). Note: Determine the left and right sides of the machine from the normal operating position. Think Safety First Operating Safety Please carefully read all of the safety instructions and decals in the safety section. - Page 14 DANGER In certain conditions during fueling, static electricity can be released causing a spark which can ignite the gasoline vapors. A fire or explosion from gasoline can burn you and others and can damage property. • Always place gasoline containers on the ground away from your vehicle before filling.

-

Page 15: Before Starting

• The blades are disengaged. Overfilling may result in fuel leakage or damage to the engine or emission system. • The motion control levers are in the park position. 1. Clean around the fuel tank cap and remove the cap. The safety interlock system also is designed to stop the engine whenever the control levers are out of the park Note: You can use the fuel window to verify... -

Page 16: Starting The Engine

Checking the Engine Oil Level Before you start the engine and use the machine, check the oil level in the engine crankcase; refer to Checking the Oil Level in the Engine Maintenance section. Starting the Engine 1. Sit down on the seat and move the motion controls outward to the park position. -

Page 17: Operating The Blades

Figure 14 1. Control panel 2. Blade control switch—On position Figure 13 Disengaging the Blades 1. Control panel 4. Off 2. Ignition key—run position 5. Run Push down on the blade control switch to move it to 3. Ignition key—start position 6. Start the Off position and disengage the blades (Figure 15). -

Page 18: Stopping The Engine

engine; the engine should not crank. Repeat with the other motion control lever. 3. While sitting on the seat, move the blade control switch to Off, and lock the motion control levers in the park position. Start the engine. While the engine is running, engage the blade control switch, and rise slightly from the seat;... -

Page 19: Stopping The Machine

Backward 1. Move the motion control levers to neutral and outward to the park position; disengage the blade 1. Move the levers to the center, unlocked position. control switch. 2. To go backward, look behind you and down as you slowly pull the motion control levers rearward WARNING (Figure 19). -

Page 20: Positioning The Seat

Adjusting the Motion Control Levers Adjusting the Height The motion control levers can be adjusted higher or lower for maximum operator comfort. 1. Remove the 2 bolts holding the control lever to the control arm shaft (Figure 22). 2. Move the control lever to the next set of holes. Secure the lever with the 2 bolts (Figure 22). -

Page 21: Grass Deflector

To Push the Machine Grass Deflector 1. Park the machine on a level surface and disengage The mower has a hinged grass deflector that disperses the blade control switch. clippings to the side and down toward the turf. 2. Move the motion control levers outward to park DANGER position, stop the engine, and wait for all moving parts to stop before leaving the operating position. - Page 22 Toro replacement blade. Mowing Direction Alternate mowing direction to keep the grass standing straight. This also helps disperse clippings which enhances decomposition and fertilization.

-

Page 23: Maintenance

Maintenance Note: Determine the left and right sides of the machine from the normal operating position. Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Check the safety interlock system. • Check the air cleaner for dirty, loose or damaged parts. •... -

Page 24: Lubrication

Lubrication 4. Connect a grease gun to each fitting (Figure 24 and Figure 25). Pump grease into the fittings until grease begins to ooze out of the bearings. Greasing the Bearings 5. Wipe up any excess grease. Service Interval: Every 25 hours—Grease all lubrication points. -

Page 25: Engine Maintenance

Engine Maintenance Replace a dirty, bent, or damaged element. Handle new elements carefully; do not use if the rubber seal is damaged. Servicing the Air Cleaner 4. Clean all air cleaner components of any accumulated dirt or foreign material. Prevent any dirt from Service Interval: Before each use or daily—Check the entering the carburetor. - Page 26 2. Disengage the blade control switch and move the motion controls outward to the park position. 3. Stop the engine, remove the key, and wait for all moving parts to stop before leaving the operating position. 4. Clean the area around the drain valve and on the machine frame.

-

Page 27: Servicing The Spark Plug

G014536 G005177 Figure 31 1. Oil filter 3. Adapter 2. Gasket 14. Slowly pour approximately 80% of the specified oil into the filler tube (Figure 28). 15. Install the oil fill cap/dipstick and push firmly into Figure 30 place (Figure 28). 1. -

Page 28: Cleaning The Blower Housing

Cleaning the Blower Housing To ensure proper cooling, make sure the grass screen, cooling fins, and other external surfaces of the engine are kept clean at all times. Annually or every 100 hours of operation (more often under extremely dusty, dirty conditions), remove the blower housing and any other cooling shrouds. -

Page 29: Fuel System Maintenance

Fuel System Maintenance DANGER In certain conditions, gasoline is extremely flammable and highly explosive. A fire or explosion from gasoline can burn you and others and can damage property. • Perform any fuel related maintenance when the engine is cold. Do this outdoors in an open area. Wipe up any gasoline that spills. -

Page 30: Electrical System Maintenance

Electrical System WARNING Maintenance Incorrect battery cable routing could damage the machine and cables causing sparks. Sparks can cause the battery gasses to explode, WARNING resulting in personal injury. • Always disconnect the negative (black) CALIFORNIA battery cable before disconnecting the Proposition 65 Warning positive (red) cable. -

Page 31: Servicing The Fuses

Figure 36 1. Positive battery post 3. Red (+) charger lead G014540 2. Negative battery post 4. Black (-) charger lead Figure 37 1. Main-30 amp 2. Charge circuit-25 amp Note: Do not run the machine with the battery disconnected, electrical damage may occur. 4. -

Page 32: Drive System Maintenance

Drive System 1. Locate the shaft on the electric brake where the brake link arms are connected. Maintenance 2. Rotate the shaft forward to release the brake. Checking the Tire Pressure Service Interval: Every 25 hours—Check tire pressure. Maintain the air pressure in the front and rear tires as specified. -

Page 33: Mower Maintenance

4. Damage wear or damage. File down any nicks and sharpen the blades as necessary. If a blade is damaged or worn, replace it immediately with a genuine Toro replacement blade. For convenient sharpening and replacement, you Checking for Bent Blades may want to keep extra blades on hand. - Page 34 The blades must be replaced if a solid object is hit, if the blade is out of balance, or the blade is bent. To ensure optimum performance and continued safety conformance of the machine, use genuine Toro replacement blades. Replacement blades made by other manufacturers may result in non-conformance with safety standards.

-

Page 35: Leveling The Mower Deck

Leveling the Mower Deck Check to ensure the mower deck is level any time you install the mower or when you see an uneven cut on your lawn. The mower deck must be checked for bent blades prior to leveling; any bent blades must be removed and replaced. - Page 36 6. Support the weight of mower deck by placing wood equivalent to 0.25 inch, while a single side is 0.125 blocks under the edges of the deck. inch (Figure 51). Adjust the height of the mower deck to the desired height. Note: Avoid placing the supports under any anti-scalp rollers if present on the deck.

-

Page 37: Removing The Mower

Removing the Mower 1. Park the machine on a level surface and disengage the blade control switch. G009658 2. Move the motion control levers outward to the park position, stop the engine, remove the key, and wait for all moving parts to stop before leaving the operating position. -

Page 38: Mower Belt Maintenance

Check the belts for cracks, frayed edges, burn marks, or mower pulleys (Figure 56). any other damage. Replace damaged belts. 6. Using a spring removal tool, (Toro part no. 92-5771), install the idler spring over the deck hook and Replacing the Mower Belt placing tension on the idler pulley and mower belt (Figure 56). -

Page 39: Replacing The Grass Deflector

6. Attach the front support rod to the mower deck with 6. Place the spring on the rod, with end wires down, the clevis pin and hairpin cotter (Figure 54). and between the grass deflector brackets. Slide rod through second grass deflector bracket (Figure 57). 7. -

Page 40: Cleaning

Cleaning Important: The grass deflector must be spring loaded in the down position. Lift the deflector up to test that it snaps to the full down position. Washing the Underside of the Mower Service Interval: Before each use or daily—Clean the mower housing. -

Page 41: Storage

Storage Note: If the mower is not clean after one washing, soak it and let it stand for 30 minutes. Then repeat the process. Cleaning and Storage 8. Run the machine and mower blades again for one to 1. Disengage the blade control switch, move the three minutes to remove excess water. - Page 42 12. Clean any dirt and chaff from the top of the mower. 13. Scrape any heavy buildup of grass and dirt from the underside of the mower, then wash the mower with a garden hose. 14. Check the condition of the drive and mower belts. 15.

-

Page 43: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The engine overheats. 1. The engine load is excessive. 1. Reduce ground speed. 2. The oil level in the crankcase is low. 2. Add oil to the crankcase. 3. The cooling fins and air passages 3. - Page 44 Problem Possible Cause Corrective Action There is abnormal vibration. 1. The engine mounting bolts are loose. 1. Tighten the engine mounting bolts. 2. The engine pulley, idler pulley, or blade 2. Tighten the appropriate pulley. pulley is loose. 3. The engine pulley is damaged. 3.

-

Page 45: Schematics

Schematics G014644 Electrical Diagram (Rev. A) - Page 46 Notes:...

- Page 47 Notes:...

- Page 48 Countries Other than the United States or Canada Customers who have purchased Toro products outside the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor's service or have difficulty obtaining guarantee information, contact the Toro importer.