Summary of Contents for Bosch Rexroth Hyquip 61 Series

- Page 1 Axial Piston Variable Double Pump RE 93010-01-B/05.09 Replaces: –.– A8VO English Series 61 and 63 Operating Instructions...

- Page 2 © This document, as well as the data, specifications and other information set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without its consent.

-

Page 3: Table Of Contents

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 3/52 Contents Contents About this document ..................4 1.1 Related documents ...................4 1.2 Abbreviations used ...................5 General safety instructions ................6 2.1 Intended use .....................6 2.2 Improper use .....................6 2.3 Personnel qualifications ................6 2.4 Safety instructions in this document ............7... -

Page 4: About This Document

4/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | About this document About this document These instructions contain important information on the safe and appropriate assembly, transport, commissioning, maintenance, disassembly and simple troubleshooting of the axial piston variable double pump A8VO series 61 and 63. -

Page 5: Abbreviations Used

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 5/52 About this document Abbreviations used As umbrella term for "axial piston variable double pump A8VO", the designation "axial piston unit" will be used in the following. Table 2: Abbreviations... -

Page 6: General Safety Instructions

6/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | General safety instructions 2 General safety instructions The axial piston unit has been manufactured according to the generally accepted rules of current technology. There is, however, still a danger of personal injury or damage to equipment if the following general safety instructions and the warnings before the steps contained in these instructions are not complied with. -

Page 7: Safety Instructions In This Document

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 7/52 General safety instructions Qualified personnel are those who can recognize possible hazards and institute the appropriate safety measures due to their professional training, knowledge, and experience, as well as their understanding of the relevant regulations pertaining to the work to be done. - Page 8 8/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | General safety instructions • Persons who assemble, commission, operate, disassemble or maintain Rexroth products must not consume any alcohol, drugs or pharmaceuticals that may affect their ability to respond.

-

Page 9: Operator's Obligations

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 9/52 General safety instructions Operator's obligations The operator of the axial piston unit from Rexroth must provide personnel training on a regular basis regarding the following subjects: • Observation and use of the operating instructions and the legal regulations •... -

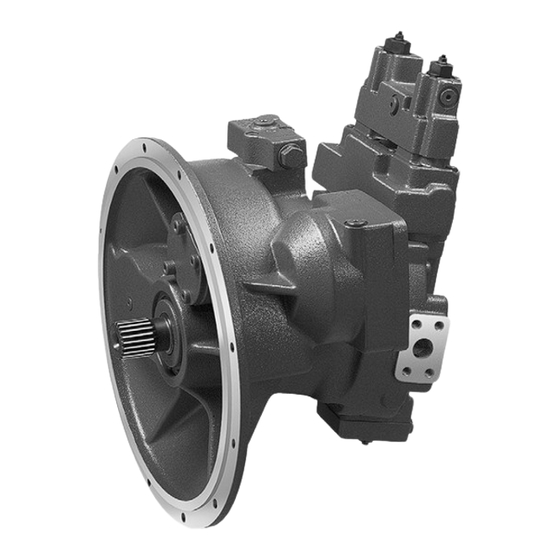

Page 10: Delivery Contents

10/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Delivery contents 3 Delivery contents Fig. 1: Axial piston unit Included in the delivery contents are: • 1 Axial piston unit The following parts are also assembled on delivery: •... -

Page 11: Product Description

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 11/52 Product description 4 Product description Performance description The axial piston variable double pump generates, controls and regulates a hydraulic fluid flow. The A8VO is suitable for direct mounting on the flywheel case of a diesel engine. - Page 12 12/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Product description 4.2.2 Functional description Pump For axial piston units with bent-axis design, the pistons (2) are arranged at an angle to the drive shaft (1). When the drive shaft is turned, the cylinder (3) is picked up and set into motion cardan-free by the pistons, which are arranged in a ring on and flexibly connected to the drive-shaft flange (7).

- Page 13 RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 13/52 Product description 4.2.3 Control devices lA0, lA1 - Individual power control For the variable double pump with LA0/LA1 individual power control, each rotary group is equipped with a separate power control.

- Page 14 14/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Product description The following variations of the individual power control without override control are available: lA0H2 • – with hydraulic stroke limiter, positive control and external pilot pressure supply •...

- Page 15 RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 15/52 Product description EP - Electrical control with With the electrical control with proportional solenoid, the pump displacement is proportional solenoid steplessly adjusted in proportion to the current by means of magnetic force.

-

Page 16: Product Identification

16/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Product description Product identification The axial piston unit can be identified with the name plate. The following example shows an name plate: A8VO Rexroth D-89275 Elchingen TYP: A8VO55LA0H2/61R1-NZG05F021... -

Page 17: Transport And Storage

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 17/52 Transport and storage 5 Transport and storage Transporting the axial piston unit CAuTION! Risk of damage! Hitting or impulsive forces on the drive shaft can damage the axial piston unit. - Page 18 18/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Transport and storage Transport with lifting strap Place the lifting strap around the axial piston unit in such a way that it passes over neither the attachment parts (e.g. valves) nor such that the axial piston unit is hung from attachment parts (see Fig.

-

Page 19: Storing The Axial Piston Unit

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 19/52 Transport and storage Storing the axial piston unit Requirement • The storage areas must be free from corrosive materials and gasses. • The storage areas must be dry. - Page 20 20/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Transport and storage For storage time up to 12 months: Moisten the inside of the axial piston unit with mineral oil and fill with approx. 100 ml mineral oil.

-

Page 21: Assembly

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 21/52 Assembly 6 Assembly Prior to assembly, the following documents must be available: • Installation drawing for the axial piston unit (available from Rexroth) • Hydraulic circuit diagram for the axial piston unit (in the installation drawing) •... - Page 22 22/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Assembly Make certain that the suction line flows into the tank below the minimum fluid level in all operational states. Fig. 8: Suction pressure Absolute pressure gauge Standard pressure gauge Make certain that a minimum suction pressure of 0.8 bar absolute is present...

-

Page 23: Installation Position

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 23/52 Assembly Installation position The following installation positions are permissible. The shown piping layout illustrates the basic layout. The case drain chamber is internally connected to the suction chamber. -

Page 24: Assembling The Axial Piston Unit

24/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Assembly Assembling the axial piston unit DANGER! Systems which are in operation pose a risk of injury! Working on operating systems poses a danger to life and limb. The work steps described in this chapter must only be performed on systems which are at a standstill. - Page 25 RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 25/52 Assembly 6.4.2 Dimensions The installation drawing contains the dimensions for all ports on the axial piston unit. Also observe the instructions provided by the manufacturers of the other components when selecting the required tools.

- Page 26 26/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Assembly 6.4.4 Installation with coupling How to assemble the axial piston unit with a coupling is described in detail in the following: Assemble the specified coupling half onto the drive shaft of the axial piston unit according to the instructions of the coupling manufacturer.

- Page 27 RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 27/52 Assembly 6.4.6 Completing assembly Remove any mounted transport screws. Remove the transport protection. The axial piston unit was delivered with protective covers and plastic plugs or locking screws. These must be removed before connecting. Use appropriate tools.

- Page 28 28/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Assembly 6.4.7 Hydraulically connecting the axial piston unit The machine or system manufacturer is responsible for dimensioning the lines. The axial piston unit must be connected to the rest of the hydraulic system in accordance with the hydraulic circuit diagram of the machine or system manufacturer.

- Page 29 RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 29/52 Assembly Notes on routing the lines Observe the following notes when routing the suction and pressure lines. Make certain that the suction line (pipe or hose) is as short and straight as possible.

- Page 30 30/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Assembly Port overview Fig. 12: Port overview A8VO, size 107 with lA0KH2 control Fig. 13: Port overview A8VO, size 140 with lA1S control Fig. 14: Port overview A8VO, size 80 with EP2 control, without auxiliary pump...

- Page 31 RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 31/52 Assembly Table 6: Ports A8VO series 61 and 63 Designa- Port for Standard Danger State tion pressure [bar] Service line SAE J518 Fixing threads DIN 13 Suction SAE J518...

- Page 32 32/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Assembly Table 7: Tightening torques of the threaded holes and locking screws Maximum permissible Required tightening torque of WAF hexagon socket for Threaded port sizes tightening torque of the...

- Page 33 RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 33/52 Assembly 6.4.8 Electrical connection of the axial piston unit The machine or system manufacturer is responsible for the layout of the electric control. For electrically controlled axial piston units, the electric control must be connected according to the circuit diagram of the system manufacturer.

-

Page 34: Commissioning

34/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Commissioning 7 Commissioning WARNING! Danger while working in the danger zone of a machine or system! It is not permissible to work in the danger zone of a machine or system. -

Page 35: First Commissioning

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 35/52 Commissioning First commissioning CAuTION! Risk of damage to the product! Any contamination of the hydraulic fluid leads to wear and malfunctions. In particular, contaminants, such as welding beads or metal cuttings in the hydraulic lines, may damage the axial piston unit. - Page 36 36/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Commissioning Danger of environmental contamination! CAuTION! The discharge or spillage of hydraulic fluid while filling the axial piston unit can lead to environmental pollution and contamination of the groundwater.

-

Page 37: Recommissioning After Standstill

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 37/52 Commissioning 7.1.4 Performing flushing cycle In order to remove foreign bodies from the system, Rexroth recommends a flushing cycle for the entire system. During the flushing cycle, the axial piston unit must be operated without load. -

Page 38: Running-In Phase

38/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Commissioning Running-in phase The bearings and sliding surfaces are subject to a running-in phase. The increased friction at the start of the running-in phase results in increased heat development which decreases with increasing operating hours. -

Page 39: Operation

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 39/52 Operation 8 Operation The product is a component which requires no settings or changes during operation. For this reason, this chapter of the instructions does not contain any information on adjustment options. -

Page 40: Maintenance And Repair

40/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Maintenance and repair 9 Maintenance and repair Cleaning and care CAuTION! Damage to the surface caused by solvents and aggressive detergents! Aggressive detergents may damage the seals on the axial piston unit and cause them to age faster. -

Page 41: Maintenance

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 41/52 Maintenance and repair Maintenance The axial piston unit is low maintenance when used as intended. The service life of the axial piston unit is heavily dependent on the quality of the hydraulic fluid. -

Page 42: Decommissioning

42/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Decommissioning 10 Decommissioning The axial piston unit is a component that does not require decommissioning. For this reason, this chapter of the instructions does not contain any information For details about how to disassemble or replace your axial piston unit, please refer to chapter "11 Disassembly and replacement". -

Page 43: Preparing The Components For Storage Or Further Use

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 43/52 Disassembly and replacement Loosen the lines and collect the escaping hydraulic fluid in the collector. Remove the axial piston unit. Use an appropriate lifting device. Completely empty the axial piston unit. -

Page 44: Disposal

44/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Disposal 12 Disposal Observe the following points when disposing of the axial piston unit: Completely empty the axial piston unit. Dispose of the hydraulic fluid according to the national regulations of your country. -

Page 45: Troubleshooting

RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 45/52 Troubleshooting 14 Troubleshooting The following table may assist you in troubleshooting. The table makes no claim for completeness. In practical use, problems which are not listed here may also occur. -

Page 46: Malfunction Table

46/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Troubleshooting 14.2 Malfunction table Table 9: Malfunction table for variable pumps Fault Possible cause Remedy Unusual noises Drive speed too high. Machine or system manufacturer. Wrong direction of rotation. - Page 47 RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 47/52 Troubleshooting Table 9: Malfunction table for variable pumps Fault Possible cause Remedy No or insufficient pressure Faulty mechanical drive Machine or system manufacturer. (e.g. defective coupling). Drive power too low.

-

Page 48: Technical Data

48/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Technical data 15 Technical data The technical data of your axial piston unit can be found in data sheet RE 93010. The data sheets can be found on the internet under www.boschrexroth.com/axial-piston-pumps... - Page 49 RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 49/52...

-

Page 50: Index

50/52 Bosch Rexroth AG A8VO Series 61 and 63 RE 93010-01-B/05.09 | Index Index Abbreviations 5 General instructions 25 Address directory 48 Assembly 11, 21, 24 Completing 27 Hydraulic fluid 35 General instructions 25 on an engine 26 Preparation 24... - Page 51 RE 93010-01-B/05.09 | A8VO Series 61 and 63 Bosch Rexroth AG 51/52 Index Recommissioning After standstill 37 Repair 41 Replacement 42 Ring screw 17 Running-in phase 38 Safety instructions 6, 7 Service line port 11 Spare parts 41 Storage 17...

- Page 52 Bosch Rexroth AG Hydraulics Axial Piston Units Glockeraustraße 2 89275 Elchingen, Germany Phone +49 (0) 73 08 - 82 0 +49 (0) 73 08 - 72 74 info.brm-ak@boschrexroth.de www.boschrexroth.com/axial-piston-pumps Printed in Germany RE 93010-01-B/05.09...