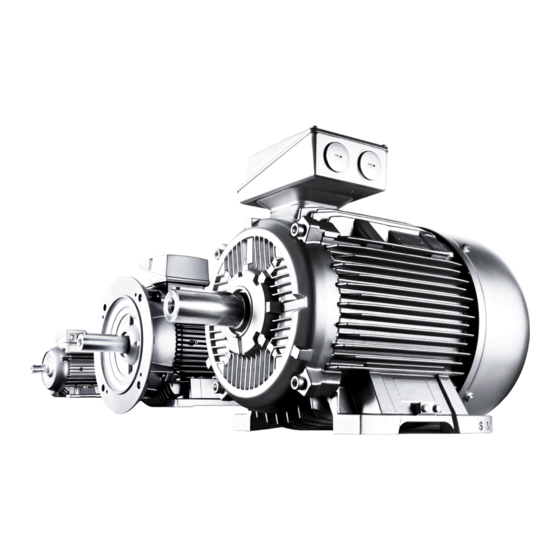

Siemens 1FP1/3 Low Voltage Motor Manuals

Manuals and User Guides for Siemens 1FP1/3 Low Voltage Motor. We have 1 Siemens 1FP1/3 Low Voltage Motor manual available for free PDF download: Operating Instructions Manual

Advertisement

Advertisement

Related Products

- Siemens SIMOTICS-T 1FW6053-B03-0F

- Siemens SIMOTICS-T 1FW6053-B15-1J

- Siemens SIMOTICS-T 1FW6063-B10-1J

- Siemens 1FK708 Series

- Siemens SIMOTICS 1FT2206-4AF

- Siemens SIMOTICS 1FT2208-4AC

- Siemens SIMOTICS 1FT2210-3AC

- Siemens SIEMOSYN 1FU8113-2TA Series

- Siemens SIEMOSYN 1FU8086-4TA Series

- Siemens SIEMOSYN 1FU8096-4TA Series