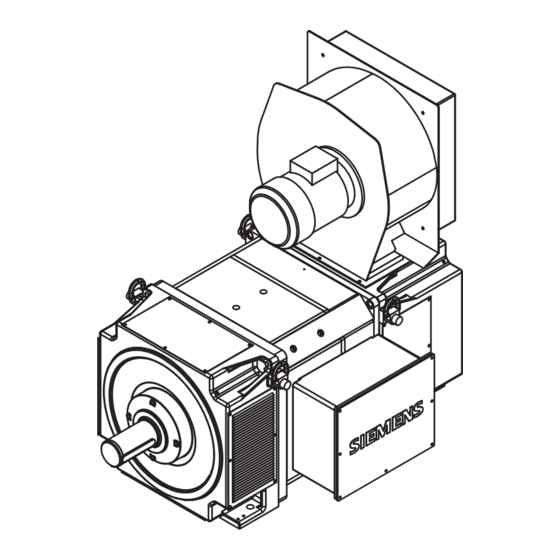

Siemens SIMOTICS DC 1GG7 Industrial Motor Manuals

Manuals and User Guides for Siemens SIMOTICS DC 1GG7 Industrial Motor. We have 1 Siemens SIMOTICS DC 1GG7 Industrial Motor manual available for free PDF download: Operating Instructions Manual

Advertisement

Advertisement