Table of Contents

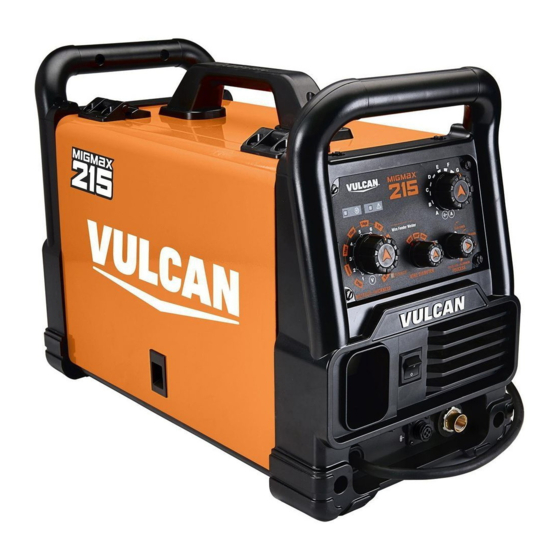

Advertisement

Advertisement

Table of Contents

Summary of Contents for Harbor Freight Tools Vulcan Migmax 215

-

Page 2: Table Of Contents

Table of Contents Safety ............2 Welding Tips ..........23 Specifications ..........7 Maintenance ..........27 Setup ............8 Parts List and Diagrams ......30 Basic Welding ..........15 Warranty ............ 32 WARNING SYMBOLS AND DEFINITIONS This is the safety alert symbol. It is used to alert you to potential personal injury hazards. - Page 3 Fume and Gas Safety INHALATION HAZARD: Welding and Plasma Cutting Produce toxic fumes. 1. Exposure to welding or cutting exhaust 3. Keep head out of fumes. fumes can increase the risk of developing Do not breathe exhaust fumes. certain cancers, such as cancer of the 4.

- Page 4 Electrical Safety ELECTRIC SHOCK can KILL. 1. Turn off, disconnect power, and 6. Do not expose welders to rain or wet conditions. discharge electrode to ground before setting Water entering a welder will increase down torch/electrode holder and before service. the risk of electric shock.

- Page 5 If unreadable or missing, contact welder’s operation. If damaged, have the Harbor Freight Tools for a replacement. welder repaired before use. Many accidents 4. Unplug before maintenance. Unplug the Welder are caused by poorly maintained welders.

- Page 6 Grounding TO PREVENT ELECTRIC SHOCK AND DEATH FROM INCORRECT GROUNDING WIRE CONNECTION: Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. Do not use the Welder if the power cord or plug is damaged. If damaged, have it repaired by a service facility before use.

- Page 7 Symbology Wire Feed (Speed) Inches Per Minute American Wire Gauge Workpiece Ground Cable Electric Shock Hazard. Torch Cable Do not touch energized parts. Overheat Shutdown Indicator Inhalation Hazard. Keep head out of fumes and use proper ventilation. Cooling Fan Read manual before Housing Ground Point setup and/or use.

- Page 8 Setup Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual including all text under subheadings therein before set up or use of this product. TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION: Turn the Power Switch off and unplug the Welder before setup. Note: Remove the protective foam and cardboard from the Welder before setup.

- Page 9 Spool Knob 6. 10-12 Pound Wire Spool Installation: Remove the Wingnut and Spacer. If replacing a Spool, remove the old Spool Wingnut and all remaining wire from the liners. Spacer 7. Place the Spool Adapter over the Spool Spindle and against the Spool Brake Pad as illustrated. 10-12 lb Wire Spool Spool Spindle...

- Page 10 DCEP Solid Core (Gas Shielded) Polarity Setup 12. DCEP Direct Current Electrode Positive Wire Setup for Solid Core (gas shielded) welding: a. Remove the two Wingnuts securing the cables. Connect the Black Ground Cable to the – negative ( ) Terminal using the Wingnut. Connect the Red Cable to the positive (+) Terminal using the other Wingnut.

- Page 11 Feed Tensioner Idler Arm 13. Turn the Feed Tensioner knob counterclockwise to loosen it enough to pull it down to remove tension. The spring-loaded Idler Arm will move up as shown. Feed Roller 14. Feed Roller Instructions: Knob Check that the Feed Roller is correct for the type of wire being used (solid core or flux- cored) and that it is turned to properly match the wire size marked on the Wire Spool:...

- Page 12 Wire Feed Mechanism 15. Loosen the Knob on the Wire Feed Gun Cable mechanism, then insert the Gun Cable Connector Connector through the hole on the Welder front and into the socket on the Wire Feed. Knob 16. Ensure that the Gun Cable Connector is fully inserted into the socket on the Wire Feed mechanism as shown, Incorrect ...

- Page 13 Idler Arm Feed Tensioner 20. Make sure the welding wire is resting in the groove of the Feed Roller, then push the wire Idler Arm down, and swing the Feed Tensioner up to latch it across the tip of the arm. After the wire is held by the Tensioner, you may release it.

- Page 14 Power Switch 25. Do not touch the Gun’s Trigger. Plug the Power Cord into a properly grounded, GFCI protected 120 V AC (20 amp rated) or 240 V AC receptacle that matches the plug and turn the Power Switch ON. The circuit must be equipped with delayed action-type circuit breaker or fuses.

- Page 15 Basic Welding Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual including all text under subheadings therein before welding. TO PREVENT SERIOUS INJURY: Protective gear must be worn when using the Welder; minimum shade number 10 full face shield (or welding mask), ear protection, welding gloves, sleeves and apron, NIOSH-approved respirator, and fire resistant work clothes without pockets should be worn when welding.

- Page 16 Front Panel Controls Voltage Input / Thermal Overload Indicator Power ON Indicator Process Selection Knob Material Thickness / Wire Speed Voltage Knob Knob Synergic Indicator Power Switch MIG Gun / Wire Diameter Spool Gun Selection Knob Cable Socket Wire Feed Spool Gun Control Socket Gas Outlet...

- Page 17 Interior Controls Cold Wire Feed Switch Feed Tensioner Wire Feed Mechanism Idler Wire Spool Spool Knob Feed Roller Knob Wire Inlet Liner Polarity Cables Note: When using an optional Spool Gun (sold separately), connect the Spool Gun gas hose to the Spool Gun Gas Outlet (see Front Panel Controls on previous page). Weld Settings Refer to the Settings Chart on the inside of the Welder door for Flux-Cored and MIG Weld settings.

- Page 18 Duty Cycle (Duration of Use) Avoid damage to the Welder by not welding for more than the prescribed duty cycle time. The Duty Cycle defines the number of minutes, within a 10 minute period, during which a given welder can produce a particular 40% Use at 100A welding current without overheating.

- Page 19 Setting Up The Weld 1. Make practice welds on pieces of scrap the same thickness as your intended workpiece to practice technique before welding anything of value. Clean the weld surfaces thoroughly with a wire brush or angle grinder; there must be no rust, paint, oil, or other materials clamps on the weld surfaces, only bare metal.

- Page 20 Power 5. Set MIG Gun down on nonconductive, Switch nonflammable surface away from any grounded objects. Turn the Power Switch ON. 6. Settings - Refer to Label on the inside of the Welder door. a. Auto (Synergic) Settings – Synergic Indicator will light: •...

- Page 21 Basic Welding Technique 1. Press (and hold) MIG Gun Trigger and contact the area to be welded with electrode wire to ignite arc. stringer bead weave bead 2. For a narrow weld, you can usually draw the wire in a steady straight line. This is called a stringer bead.

- Page 22 Note: If Welder is used too long, the Overload Indicator lights up and the unit automatically shuts down. The Welder automatically returns MIG Gun Overload to service after cooling off. Should this occur, Indicator rest the MIG Gun on an electrically non- conductive, heat-proof surface, such as a Power concrete slab, away from the ground clamp.

- Page 23 Welding Tips A typical flux-cored wire (FCAW) weld before cleaning. weld bead slag spatter A good way to test welding technique is to examine a weld’s appearance after it has cooled and the slag base metal has been removed. Then, better welding can be learned by adjusting your weld technique to remedy A typical solid wire (GMAW) weld any problems found.

- Page 24 Weld Diagnosis Workpiece Heat Control / Weld Penetration EXCESS PENETRATION OR INADEQUATE PENETRATION PROPER PENETRATION BURN-THROUGH Not hot enough Ideal heat Too hot How to increase workpiece heat How to reduce workpiece heat and increase penetration: and limit penetration: (to weld THICKER workpieces properly) (to weld THINNER workpieces properly) a.

- Page 25 Weld Problems Penetration (Workpiece Heat Control) EXCESS PENETRATION OR PROPER PENETRATION INADEQUATE PENETRATION BURN-THROUGH Weld is visible underneath and Weld does not penetrate the Weld droops on top and bulges slightly on top. joint fully, just on the surface. underneath, or falls through entirely, making a hole.

- Page 26 Porosity Excessive Spatter Small cavities or holes in the bead. Fine spatter is normal. Spatter that is grainy and large is a problem. VIEW VIEW POSSIBLE CAUSES AND SOLUTIONS POSSIBLE CAUSES AND SOLUTIONS 1. Incorrect polarity: Check that polarity is set correctly 1.

- Page 27 Maintenance TO PREVENT SERIOUS INJURY, FIRE AND BURNS: Unplug the Welder, rest the MIG Gun on a heat-proof, electrically non-conductive surface, and allow all parts of the Welder to cool thoroughly before service. 1. BEFORE EACH USE, inspect the general 2.

- Page 28 Troubleshooting IMPORTANT! Be CERTAIN to shut off the Welder, disconnect it from power, and discharge the MIG Gun to ground before adjusting, cleaning, or repairing the unit. Problem Possible Causes Likely Solutions 1. Insufficient wire feed pressure. 1. Increase wire feed pressure properly. Follow step 27 on page 14.

- Page 29 Troubleshooting (continued) IMPORTANT! Be CERTAIN to shut off the Welder, disconnect it from power, and discharge the MIG Gun to ground before adjusting, cleaning, or repairing the unit. Problem Possible Causes Likely Solutions 1. Tripped thermal protection device. 1. If the Voltage Input/Thermal Overload Indicator is illuminated, Welder has overheated and shut down.

-

Page 30: Wiring Diagram

Parts List and Diagrams Wiring Diagram Wire Feed Motor Drawing Wire Motor Gas Valve 1 Gas Valve 2 Touch Switch Gas Valve 1 Gas Valve 2 Main Board Hall Sensor Switch ∼ OUT+ ∼ RECITIFIER ∼ Fuse ∼ IGBT OUT- FAN2 FAN1 FAN2... - Page 31 Assembly Diagram Record Serial Number Here: Note: If product has no serial number, record Note: Some parts are listed and shown for month and year of purchase instead. illustration purposes only, and are not available individually as replacement parts. Item 63617 For technical questions, please call 1-888-380-0318.

-

Page 32: Please Read The Following Carefully

Limited One Year Warranty Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards, and warrants to the original purchaser that this product is free from defects in materials and workmanship for the period of one year from the date of purchase. - Page 33 No portion of this manual or any artwork contained herein may be reproduced in Failure to do so can result in serious injury. any shape or form without the express written consent of Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing SAVE THIS MANUAL.

-

Page 34: Safety

Table of Contents Safety ............2 Welding Tips ..........23 Specifications ..........7 Maintenance ..........27 Setup ............8 Parts List and Diagrams ......30 Basic Welding ..........15 Warranty ............ 32 WARNING SYMBOLS AND DEFINITIONS This is the safety alert symbol. It is used to alert you to potential personal injury hazards. - Page 35 Fume and Gas Safety INHALATION HAZARD: Welding and Plasma Cutting Produce toxic fumes. 1. Exposure to welding or cutting exhaust 3. Keep head out of fumes. fumes can increase the risk of developing Do not breathe exhaust fumes. certain cancers, such as cancer of the 4.

- Page 36 Electrical Safety ELECTRIC SHOCK can KILL. 1. Turn off, disconnect power, and 6. Do not expose welders to rain or wet conditions. discharge electrode to ground before setting Water entering a welder will increase down torch/electrode holder and before service. the risk of electric shock.

- Page 37 If unreadable or missing, contact welder’s operation. If damaged, have the Harbor Freight Tools for a replacement. welder repaired before use. Many accidents 4. Unplug before maintenance. Unplug the Welder are caused by poorly maintained welders.

- Page 38 Grounding TO PREVENT ELECTRIC SHOCK AND DEATH FROM INCORRECT GROUNDING WIRE CONNECTION: Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. Do not use the Welder if the power cord or plug is damaged. If damaged, have it repaired by a service facility before use.

-

Page 39: Specifications

Symbology Wire Feed (Speed) Inches Per Minute American Wire Gauge Workpiece Ground Cable Electric Shock Hazard. Torch Cable Do not touch energized parts. Overheat Shutdown Indicator Inhalation Hazard. Keep head out of fumes and use proper ventilation. Cooling Fan Read manual before Housing Ground Point setup and/or use. -

Page 40: Setup

Setup Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual including all text under subheadings therein before set up or use of this product. TO PREVENT SERIOUS INJURY FROM ACCIDENTAL OPERATION: Turn the Power Switch off and unplug the Welder before setup. Note: Remove the protective foam and cardboard from the Welder before setup. - Page 41 Spool Knob 6. 10-12 Pound Wire Spool Installation: Remove the Wingnut and Spacer. If replacing a Spool, remove the old Spool Wingnut and all remaining wire from the liners. Spacer 7. Place the Spool Adapter over the Spool Spindle and against the Spool Brake Pad as illustrated. 10-12 lb Wire Spool Spool Spindle...

- Page 42 DCEP Solid Core (Gas Shielded) Polarity Setup 12. DCEP Direct Current Electrode Positive Wire Setup for Solid Core (gas shielded) welding: a. Remove the two Wingnuts securing the cables. Connect the Black Ground Cable to the – negative ( ) Terminal using the Wingnut. Connect the Red Cable to the positive (+) Terminal using the other Wingnut.

- Page 43 Feed Tensioner Idler Arm 13. Turn the Feed Tensioner knob counterclockwise to loosen it enough to pull it down to remove tension. The spring-loaded Idler Arm will move up as shown. Feed Roller 14. Feed Roller Instructions: Knob Check that the Feed Roller is correct for the type of wire being used (solid core or flux- cored) and that it is turned to properly match the wire size marked on the Wire Spool:...

- Page 44 Wire Feed Mechanism 15. Loosen the Knob on the Wire Feed Gun Cable mechanism, then insert the Gun Cable Connector Connector through the hole on the Welder front and into the socket on the Wire Feed. Knob 16. Ensure that the Gun Cable Connector is fully inserted into the socket on the Wire Feed mechanism as shown, Incorrect ...

- Page 45 Idler Arm Feed Tensioner 20. Make sure the welding wire is resting in the groove of the Feed Roller, then push the wire Idler Arm down, and swing the Feed Tensioner up to latch it across the tip of the arm. After the wire is held by the Tensioner, you may release it.

- Page 46 Power Switch 25. Do not touch the Gun’s Trigger. Plug the Power Cord into a properly grounded, GFCI protected 120 V AC (20 amp rated) or 240 V AC receptacle that matches the plug and turn the Power Switch ON. The circuit must be equipped with delayed action-type circuit breaker or fuses.

-

Page 47: Basic Welding

Basic Welding Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual including all text under subheadings therein before welding. TO PREVENT SERIOUS INJURY: Protective gear must be worn when using the Welder; minimum shade number 10 full face shield (or welding mask), ear protection, welding gloves, sleeves and apron, NIOSH-approved respirator, and fire resistant work clothes without pockets should be worn when welding. - Page 48 Front Panel Controls Voltage Input / Thermal Overload Indicator Power ON Indicator Process Selection Knob Material Thickness / Wire Speed Voltage Knob Knob Synergic Indicator Power Switch MIG Gun / Wire Diameter Spool Gun Selection Knob Cable Socket Wire Feed Spool Gun Control Socket Gas Outlet...

- Page 49 Interior Controls Cold Wire Feed Switch Feed Tensioner Wire Feed Mechanism Idler Wire Spool Spool Knob Feed Roller Knob Wire Inlet Liner Polarity Cables Note: When using an optional Spool Gun (sold separately), connect the Spool Gun gas hose to the Spool Gun Gas Outlet (see Front Panel Controls on previous page). Weld Settings Refer to the Settings Chart on the inside of the Welder door for Flux-Cored and MIG Weld settings.

- Page 50 Duty Cycle (Duration of Use) Avoid damage to the Welder by not welding for more than the prescribed duty cycle time. The Duty Cycle defines the number of minutes, within a 10 minute period, during which a given welder can produce a particular welding current without overheating.

- Page 51 Setting Up The Weld 1. Make practice welds on pieces of scrap the same thickness as your intended workpiece to practice technique before welding anything of value. Clean the weld surfaces thoroughly with a wire brush or angle grinder; there must be no rust, paint, oil, or other materials clamps on the weld surfaces, only bare metal.

- Page 52 Power 5. Set MIG Gun down on nonconductive, Switch nonflammable surface away from any grounded objects. Turn the Power Switch ON. 6. Settings - Refer to Label on the inside of the Welder door. a. Auto (Synergic) Settings – Synergic Indicator will light: •...

- Page 53 Basic Welding Technique 1. Press (and hold) MIG Gun Trigger and contact the area to be welded with electrode wire to ignite arc. stringer bead weave bead 2. For a narrow weld, you can usually draw the wire in a steady straight line. This is called a stringer bead.

- Page 54 Note: If Welder is used too long, the Overload Indicator lights up and the unit automatically shuts down. The Welder automatically returns MIG Gun Overload to service after cooling off. Should this occur, Indicator rest the MIG Gun on an electrically non- conductive, heat-proof surface, such as a Power concrete slab, away from the ground clamp.

-

Page 55: Welding Tips

Welding Tips A typical flux-cored wire (FCAW) weld before cleaning. weld bead slag spatter A good way to test welding technique is to examine a weld’s appearance after it has cooled and the slag base metal has been removed. Then, better welding can be learned by adjusting your weld technique to remedy A typical solid wire (GMAW) weld any problems found. - Page 56 Weld Diagnosis Workpiece Heat Control / Weld Penetration EXCESS PENETRATION OR INADEQUATE PENETRATION PROPER PENETRATION BURN-THROUGH Not hot enough Ideal heat Too hot How to increase workpiece heat How to reduce workpiece heat and increase penetration: and limit penetration: (to weld THICKER workpieces properly) (to weld THINNER workpieces properly) a.

- Page 57 Weld Problems Penetration (Workpiece Heat Control) EXCESS PENETRATION OR PROPER PENETRATION INADEQUATE PENETRATION BURN-THROUGH Weld is visible underneath and Weld does not penetrate the Weld droops on top and bulges slightly on top. joint fully, just on the surface. underneath, or falls through entirely, making a hole.

- Page 58 Porosity Excessive Spatter Small cavities or holes in the bead. Fine spatter is normal. Spatter that is grainy and large is a problem. VIEW VIEW POSSIBLE CAUSES AND SOLUTIONS POSSIBLE CAUSES AND SOLUTIONS 1. Incorrect polarity: Check that polarity is set correctly 1.

-

Page 59: Maintenance

Maintenance TO PREVENT SERIOUS INJURY, FIRE AND BURNS: Unplug the Welder, rest the MIG Gun on a heat-proof, electrically non-conductive surface, and allow all parts of the Welder to cool thoroughly before service. 1. BEFORE EACH USE, inspect the general 2. - Page 60 Troubleshooting IMPORTANT! Be CERTAIN to shut off the Welder, disconnect it from power, and discharge the MIG Gun to ground before adjusting, cleaning, or repairing the unit. Problem Possible Causes Likely Solutions 1. Insufficient wire feed pressure. 1. Increase wire feed pressure properly. Follow step 27 on page 14.

- Page 61 Troubleshooting (continued) IMPORTANT! Be CERTAIN to shut off the Welder, disconnect it from power, and discharge the MIG Gun to ground before adjusting, cleaning, or repairing the unit. Problem Possible Causes Likely Solutions 1. Tripped thermal protection device. 1. If the Voltage Input/Thermal Overload Indicator is illuminated, Welder has overheated and shut down.

-

Page 62: Parts List And Diagrams

Parts List and Diagrams Wiring Diagram Wire Feed Motor Drawing Wire Motor Gas Valve 1 Gas Valve 2 Touch Switch Gas Valve 1 Gas Valve 2 Main Board Hall Sensor Switch ∼ OUT+ ∼ RECITIFIER ∼ Fuse ∼ IGBT OUT- FAN2 FAN1 FAN2... - Page 63 Assembly Diagram Record Serial Number Here: Note: If product has no serial number, record Note: Some parts are listed and shown for month and year of purchase instead. illustration purposes only, and are not available individually as replacement parts. Item 63617 For technical questions, please call 1-888-380-0318.

-

Page 64: Warranty

Limited One Year Warranty Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards, and warrants to the original purchaser that this product is free from defects in materials and workmanship for the period of one year from the date of purchase.