Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ABB MTAC-01

- Page 1 ABB Drives User’s Manual Pulse Encoder Interface Module MTAC-01...

- Page 3 Pulse Encoder Interface Module MTAC-01 User’s Manual 3AFE68591091 REV B EFFECTIVE: 04.04.2006 © 2006 ABB Oy. All Rights Reserved.

-

Page 5: Safety

Safety Overview This chapter states the general safety instructions that must be followed when installing and operating the MTAC-01 Pulse Encoder Interface module. The material in this chapter must be studied before attempting any work on, or with, the unit. - Page 6 Safety...

-

Page 7: Table Of Contents

Table of contents Safety ............5 Overview . - Page 8 Table of contents...

-

Page 9: Installation

Installation Preparing for installation MTAC-01 module The MTAC-01 Pulse Encoder Interface module is an interface for connecting a digital pulse encoder to an ACS350 drive. A pulse encoder should be used if accurate speed or position (angle) feedback from the motor shaft is required. -

Page 10: Installing The Module

4. Ensure that the panel port adapter is attached to either the panel port of the drive or the mate part of the MTAC-01 module. 5. Gently and firmly install the MTAC-01 module to the drive’s panel slot directly from the front. - Page 11 Note: Correct insertion and tightening of the screw is essential for fulfilling the EMC requirements and proper operation of the module. 7. Install the possible control panel or panel cover on the MTAC-01 module. Installation...

- Page 12 Wiring – General The pulse encoder should be connected to the MTAC-01 module with cables as specified below. 4 × (2+1) twisted pair cable with Cable construction individual and overall shields Conductor cross-sectional area 0.5 to 1.5 mm 20 to 16 AWG...

- Page 13 Wiring – Encoder power The MTAC-01 module does not supply power for the encoder. An external power supply (as diagrammed below) is recommended. The drive’s 24 VDC supply from terminals X1A:9 (+24V) and X1A:10 (GND) can be used if the total draw on the supply does not exceed 200 mA.

- Page 14 2. Refer to Wiring diagrams on page 16, select the appropriate diagram, and wire the encoder. Note: Normally, ground the cable shield only at the drive end. However, if the encoder is isolated from the motor and from the ground, connect the cable shields to both the MTAC module and the encoder housing.

- Page 15 Option B: Functional test. For this test: • Temporarily, switch the drive to scalar mode [parameter 9904 MOTOR CTRL MODE = 3 (SCALAR:FREQ)], if not already there. • Run the drive in the forward direction. • Verify that parameter 0147 MECH REVS is increasing in the positive direction.

-

Page 16: Wiring Diagrams

• Encoder A/1 and B/2 should be wired to MTAC terminals B and A, respectively. • Encoder A/1 and B/2 (if present) should be wired to MTAC terminals B and A, respectively. Differential connection MTAC-01 module Encoder power supply Encoder... - Page 17 Single-ended connection MTAC-01 module Encoder power supply Encoder 0V V 1) Connect the cable shield at the encoder housing, if, and only if, the encoder is isolated from the motor, and from the ground. Installation...

- Page 18 Pulse A/1 leads as diagrammed on the right. For encoders with pulse B/2 leading, change the diagram for these connections: • Encoder A/1 and B/2 should be wired to MTAC terminals B and A, respectively. MTAC-01 module Encoder power supply Encoder 0V V 1) Connect the cable shield at the encoder housing, if, and only if, the encoder is isolated from the motor, and from the ground.

- Page 19 Pulse A/1 leads as diagrammed on the right. For encoders with pulse B/2 leading, change the diagram for these connections: • Encoder A/1 and B/2 should be wired to MTAC terminals B and A, respectively. MTAC-01 module Encoder power supply Encoder 0V V 1) Connect the cable shield at the encoder housing, if, and only if, the encoder is isolated from the motor, and from the ground.

-

Page 20: Start-Up

Start-up Configuration To configure the operation of the MTAC-01 module: 1. Power up the drive. 2. Use the control panel on the drive or the DriveWindow Light PC tool and set group 50 ENCODER parameters described on page 21. Encoder operating data The following actual signals, based on measurements or calculations, provide feedback from the encoder. -

Page 21: Encoder

Encoder parameters This group defines the set-up for encoder use: • Sets the number of encoder pulses per shaft revolution. • Enables the encoder operation. • Defines how the mechanical angle and revolution data is reset. Index Name/ Description Default Selection FbEq 50 ENCODER... -

Page 22: Timer & Counter

Counter The encoder pulses can be used as the signal source for the counter. For more information on the counter function, refer to chapter Program features in ACS350 User’s Manual [3AFE68462401 (English)]. Index Name/ Description Default Selection FbEq 19 TIMER & COUNTER 1906 COUNTER Selects the input signal source for the counter. -

Page 23: Diagnostics

Diagnostics Faults/Alarms If the ACS350 detects that the encoder signal is lost, the drive operation and the diagnostic message are both controlled by parameter 5003 ENCODER FAULT: • 5003 = 1 (FAULT) – The drive generates a fault (23 ENCODER ERR), and the motor coasts to a stop. •... -

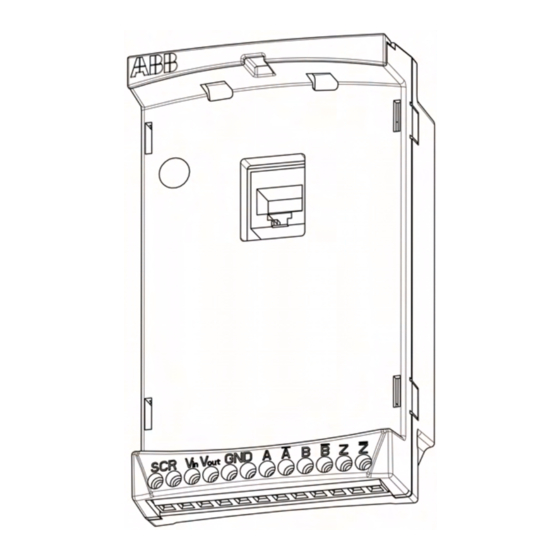

Page 24: Technical Data

Technical data Dimensions Module dimensions are shown in the figure below. 63 [2.48] 70 [2.77] 46 [1.81] 3AFE68580064-A Degree of protection The degree of protection of MTAC-01 is IP20 / UL open. Technical data... -

Page 25: Ambient Conditions

• two RJ-45 connectors for panel pass-through • 6-pin connector for drive interface • grounding screw/stand-off for connection of the SCR terminals of the drive and the MTAC-01 module. Specifications Module specifications The MTAC-01 module: • supports three channels: CH A, CH B, CH Z •... - Page 26 Technical data...

- Page 28 WA4 4BT UNITED KINGDOM Telephone +44 1925 741111 +44 1925 74121 ABB Oy ABB Inc. ABB Beijing Drive Systems Co. Ltd. AC Drives Automation Technologies No. 1, Block D, A-10 Jiuxianqiao Beilu P.O. Box 184 Drives & Motors Chaoyang District...