Table of Contents

Advertisement

Quick Links

INSTALLATION

INSTRUCTION

CONTENTS

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

SEE THE FOLLOWING PAGE FOR A COMPLETE TABLE OF

CONTENTS.

CAUTION:READ ALL SAFETY GUIDES BEFORE YOU

START TO INSTALL YOUR UNIT.

SAVE THIS MANUAL

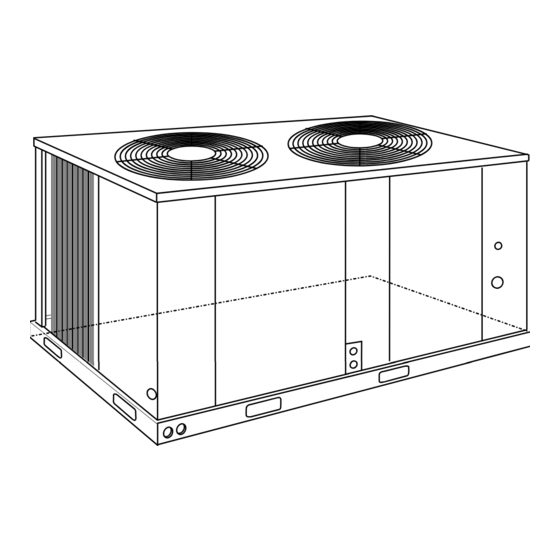

SPLIT-SYSTEM HEAT PUMPS

OUTDOOR UNITS

MODEL: EA120

035-18549-000-B-0402

Advertisement

Table of Contents

Summary of Contents for Unitary products group EA120

- Page 1 SPLIT-SYSTEM HEAT PUMPS INSTRUCTION OUTDOOR UNITS MODEL: EA120 CONTENTS GENERAL INFORMATION ......3 INSTALLATION.

-

Page 2: Table Of Contents

Emergency Heat Operation ....19 Refrigerant Line Charge ....11 Unitary Products Group... -

Page 3: General

The above forms may be ordered from: INCORRECT INSTALLATION MAY CREATE A CONDITION WHERE THE OPERATION OF Standard Register THE PRODUCT COULD CAUSE PERSONAL Norman, OK 73069 INJURY OR PROPERTY DAMAGE. TOLL FREE: Tel. 877-318-9675/Fax. 877-379-7920 Unitary Products Group... -

Page 4: Nomenclature

B = Disconnect AA = None Additional Options AC = Technicoated Coil Product Generation 1 = 1st Generation 2 = 2nd Generation Product Style A = Style A B = Style B *NOT AVAILABLE IN HEAT PUMP Unitary Products Group... -

Page 5: Installation

3. The outdoor unit should not be installed beneath The units must be installed on a substantial base that windows or between structures where normal will not settle. Any strain on the refrigerant lines may operating sounds may be objectionable. cause a refrigerant leak. Unitary Products Group... -

Page 6: Rigging And Handling

All units require certain minimum clearances for proper Rig the unit by attaching nylon straps with hooks to the operation and service. Refer to Figure 4 for these lifting holes provided in the base rails. Spreaders, clearances. whose length exceeds the largest dimension across Unitary Products Group... -

Page 7: Compressors

Circulation of air to the thermostat should not be blocked by curtains, drapes, furniture, partitions, etc. Unitary Products Group... -

Page 8: Wire Sizing

Power Size, Qty. Amps Size Supply Factor Supply (Each 0.94 @ 208V 200/230-3-60 42.0 239.0 208/230-1-60 3.03 58.6 0.84 @ 230V 460-3-60 19.2 125.0 0.86 460-1-60 27.2 Based on three, 50ºC insulated copper conductors in steel conduit. Unitary Products Group... -

Page 9: Unit Dimensions & Clearances

5-3/8 7/8 DIA CONTROL WIRING ENTRY COMPRESSOR AND 2-1/4 5-7/8 CONDENSER FAN MOTOR 32-1/2 70-1/2 ACCESS 1-3/8 DIA. 7/8" KNOCKOUT POWER WIRING ACCESSORY WIRING ENTRY ENTRY CONDENSER FAN MOTOR ACCESS FIGURE 4 - UNIT DIMENSIONS AND CLEARANCES Unitary Products Group... -

Page 10: Line Sizing

THE LIQUID LINE - The vertical rise should never exceed 50 feet because liquid refrigerant will lose 0.5 FIGURE 5 - FIELD PIPING DIAGRAMS psi of static head for each vertical foot. (Cooling/Heating Refrigerant Flow) Unitary Products Group... -

Page 11: Service Valves

These friction losses do not include any allowance for fittings. Only use a DO NOT release the entire holding charge. 1-1/8” riser when the indoor unit is above the outdoor unit. Unitary Products Group... - Page 12 2. Move the dry nitrogen supply from the access port removed from a service valve, coil connection, on the liquid line service valve of the outdoor unit to etc. the hole through the vapor disc on the indoor unit. Unitary Products Group...

-

Page 13: Evacuating And Charging

5. After the disc has been removed, burnish the exter- Open the liquid and vapor line service valves fully to nal surfaces and clean the internal surfaces of the close their access ports after the system has been vapor connection and the vapor piping. charged. Unitary Products Group... -

Page 14: Balance Point Setting

SCREWS COPPER 2 SCREWS CORNER SIDE VIEW POST (AS SHIPPED) UNIT PUSH SERVICE WALL PORTS THROUGH TOP VIEW CORNER POST SERVICE PORTS TIGHTEN SCREWS EXTENDED SIDE VIEW SERVICE PORTS EXTENDED FIGURE 6 - EXTENDING THE SERVICE PORTS Unitary Products Group... -

Page 15: Refrigerant Flow Diagram

035-18549-000-B-0402 FIGURE 7 - REFRIGERANT FLOW DIAGRAM Unitary Products Group... -

Page 16: Charging Curve

035-18549-000-B-0402 EA120 Charge Curve 115º Ambient 105º Ambient 95º Ambient 85º Ambient 75º Ambient Suction Pressure FIGURE 8 - CHARGING CURVE EA120 Unitary Products Group... -

Page 17: Operation

“AUTO” position, the blower will operate only PLACE AFTER THE RESET BEFORE THE UNIT when the thermostat calls for cooling operation. WILL RESTART. 3. When TC1 of the thermostat closes on a demand for cooling, a circuit is made from terminal Y Unitary Products Group... -

Page 18: Heating Operation

Opening and closing the power supply main dis- 4. At defrost termination, the unit returns to the nor- connect switch. mal heating operation. Unitary Products Group... -

Page 19: Operation Below 0ºf

4. Indoor section blower will also be controlled by first trolled by the first stage heating TH1 of the room stage heating TH1 if fan switch is in the “AUTO” thermostat if the fan switch is in the “AUTO” posi- position. tion. Unitary Products Group... -

Page 20: Start-Up

8. Are any refrigerant lines touching each other or any nect switch inspect factory wiring sheet metal surface? Rubbing due to vibration connections and bolted surfaces for tightness. could cause a refrigerant leak. Unitary Products Group... -

Page 21: Safety Features

3. Every compressor is protected by crankcase heat- tings within the limitations of the system, how the ers to prevent refrigerant from accumulating in the defrost cycle is controlled and how the anti-cycle timer crankcases of the compressor during an “OFF” operates. cycle. Unitary Products Group... -

Page 22: Maintenance

The outdoor fan motors are equipped with factory lubri- remove the blockage. Reset the thermostat and wait 5 cated and sealed ball bearings. They do not require minutes. If the unit doesn’t start, call a serviceman. any maintenance. Unitary Products Group... - Page 23 035-18549-000-B-0402 NOTES Unitary Products Group...

- Page 24 NOTES Subject to change without notice. Printed in U.S.A. 035-18549-000-B-0402 Copyright © by Unitary Products Group 2002. All rights reserved. Supersedes: 035-18549-000-A-0102 Unitary 5005 Norman Products York Group Drive 73069...