Siemens SIMATIC ET 200SP System Manual

Distributed i/o system

Hide thumbs

Also See for SIMATIC ET 200SP:

- System manual (271 pages) ,

- Manual (270 pages) ,

- Operating instructions manual (166 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Siemens SIMATIC ET 200SP

- Page 1 Distributed I/O system...

- Page 2 Preface ET 200SP Documentation Guide New properties/functions SIMATIC System overview Application planning ET 200SP Distributed I/O system Installation Wiring Configuring System Manual Basics of program execution Protection Configuration control (option handling) Commissioning Maintenance Test and service functions Technical specifications Dimension drawings Accessories/spare parts Calculating the leakage resistance...

- Page 3 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 4: Preface

Notes contain important information on the product, handling the product or on part of the documentation to which you should pay particular attention. Standards You can find a dated reference to the respective standards or the EC Declaration of Conformity on the Internet (https://support.industry.siemens.com) Distributed I/O system System Manual, 09/2019, A5E03576849-AJ... - Page 5 Proper use of hardware products This equipment is only allowed to be used for the applications described in the catalog and in the technical description, and only in conjunction with non-Siemens equipment and components recommended by Siemens. Correct transport, storage, installation and assembly, as well as careful operation and maintenance, are required to ensure that the product operates safely and without faults.

- Page 6 Siemens' products and solutions undergo continuous development to make them more secure. Siemens strongly recommends that product updates are applied as soon as they are available and that the latest product versions are used. Use of product versions that are no longer supported, and failure to apply the latest updates may increase customers' exposure to cyber threats.

- Page 7 This information is provided by the Siemens Industry Online Support in the Internet (http://www.siemens.com/automation/service&support). Industry Mall The Industry Mall is the catalog and order system of Siemens AG for automation and drive solutions on the basis of Totally Integrated Automation (TIA) and Totally Integrated Power (TIP).

-

Page 8: Table Of Contents

New properties/functions ......................... 14 System overview ............................16 What is the SIMATIC ET 200SP distributed I/O system? ............16 What are fail-safe automation systems and fail-safe modules? ..........19 How are SIMATIC Safety F-systems structured with ET 200SP? .......... 20 Components .......................... - Page 9 Table of contents Installing potential distributor modules ................... 78 Installing the server module ....................79 Mounting further accessories for motor starters ..............80 5.9.1 Mounting the cover for the 500 V AC infeed bus ..............80 5.9.2 Mounting the mechanical bracket for the BaseUnit ............... 82 5.9.3 Mounting the BU cover ......................

- Page 10 Table of contents Configuring the CPU ......................134 7.2.1 Reading out the configuration ....................134 7.2.2 Addressing ..........................137 7.2.3 Process images and process image partitions ..............139 7.2.3.1 Process image - overview ..................... 139 7.2.3.2 Automatically updating process image partitions ..............140 7.2.3.3 Update process image partitions in the user program ............

- Page 11 Table of contents 11.6 Operating modes of the CPU ....................206 11.6.1 STARTUP mode ........................206 11.6.2 STOP mode ......................... 209 11.6.3 RUN mode ........................... 210 11.6.4 Operating mode transitions ....................210 11.7 CPU memory reset ......................213 11.7.1 Automatic memory reset ...................... 214 11.7.2 Manual memory reset ......................

- Page 12 Table of contents 14.4 Shipping and storage conditions ................... 281 14.5 Mechanical and climatic environmental conditions ............... 282 14.6 Insulation, protection class, degree of protection and rated voltage ........286 14.7 Use of the ET 200SP in zone 2 potentially explosive atmospheres ........288 Dimension drawings ..........................

-

Page 13: Et 200Sp Documentation Guide

ET 200SP Documentation Guide The documentation for the SIMATIC ET 200SP distributed I/O system is arranged into three areas. This arrangement enables you to access the specific content you require. Basic information The System Manual and Getting Started describe in detail the configuration, installation, wiring and commissioning of the SIMATIC ET 200SP distributed I/O system. - Page 14 ET 200SP Documentation Guide Manual Collection ET 200SP The Manual Collection contains the complete documentation on the SIMATIC ET 200SP distributed I/O system gathered together in one file. You can find the Manual Collection on the Internet (https://support.automation.siemens.com/WW/view/en/84133942). "mySupport" With "mySupport", your personal workspace, you make the most of your Industry Online Support.

-

Page 15: New Properties/Functions

New properties/functions What's new in the ET 200SP System Manual, Edition 09/2019 compared to Edition 02/2018 What's new? What are the customer benefits? Where can I find information? New con- BaseUnits BU30-MS7, A simple, wire-saving group shutdown for fail- Section Selecting motor start- tents BU30-MS8, BU30-MS9 and safe motor starters. - Page 16 New properties/functions What's new? What are the customer benefits? Where can I find information? GetSMCinfo instruction With the help of the GetSMCinfo instruction Section AUTOHOTSPOT you can respond to information provided by the memory card in the user program and if required, replace the memory card as a pre- cautionary measure.

-

Page 17: System Overview

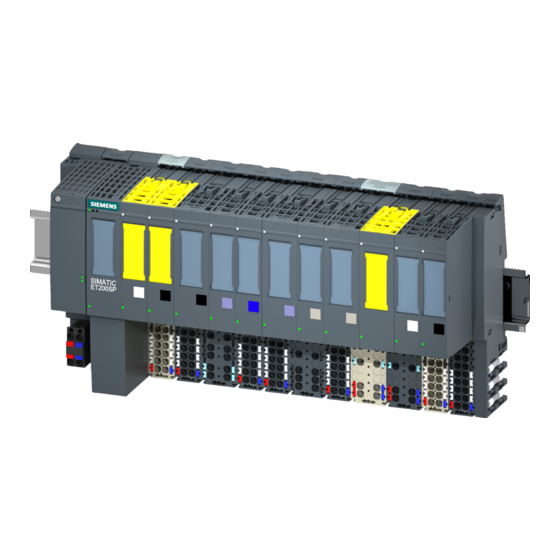

What is the SIMATIC ET 200SP distributed I/O system? SIMATIC ET 200SP SIMATIC ET 200SP is a scalable and highly flexible distributed I/O system for connecting process signals to a higher-level controller via a fieldbus. Customer benefits of the system... - Page 18 Configuration The SIMATIC ET 200SP distributed I/O system is installed on a mounting rail. It consists of: ● CPU/interface module ● Up to 64 I/O modules, which can be plugged into BaseUnits in any combination ●...

- Page 19 System overview 3.1 What is the SIMATIC ET 200SP distributed I/O system? Configuration example ① CPU/interface module ② Light-colored BaseUnit BU..D with infeed of supply voltage ③ Dark-colored BaseUnits BU..B for extending the potential group ④ BaseUnit for motor starter ⑤...

-

Page 20: What Are Fail-Safe Automation Systems And Fail-Safe Modules

Safety Integrated Safety Integrated is the integrated safety concept for automation and drive technology from Siemens. Proven technologies and systems from automation technology are used for safety systems. Safety Integrated includes the complete safety sequence, ranging from sensor, actuator and fail-safe modules right through to the controller, including safety-related communication via standard fieldbuses. -

Page 21: How Are Simatic Safety F-Systems Structured With Et 200Sp

System overview 3.3 How are SIMATIC Safety F-systems structured with ET 200SP? How are SIMATIC Safety F-systems structured with ET 200SP? SIMATIC Safety F-system with ET 200SP The figure below shows an example of a configuration for a SIMATIC Safety F-system with ET 200SP distributed I/O system and PROFINET IO. - Page 22 System overview 3.3 How are SIMATIC Safety F-systems structured with ET 200SP? Example of a configuration with fail-safe I/O modules ① Interface module ② Light-colored BaseUnit BU..D with infeed of supply voltage ③ Dark-colored BaseUnits BU..B for conducting the potential group further ④...

- Page 23 System overview 3.3 How are SIMATIC Safety F-systems structured with ET 200SP? Hardware and software requirements Fail-safe modules ET 200SP are supported by IM155-6PN ST interface modules as of firmware V1.1.1, IM155-6PN HF as of firmware V2.0, IM155-6PN HS as of firmware V4.0 and IM155-6DP HF as of firmware V1.0.

- Page 24 System overview 3.3 How are SIMATIC Safety F-systems structured with ET 200SP? Achievable safety classes The fail-safe modules are equipped with integrated safety functions for safety mode. You can achieve the safety classes of the table below: ● With the appropriate parameter assignment of the safety functions in STEP 7 ●...

-

Page 25: Components

System overview 3.4 Components Components Basic components of the ET 200SP distributed I/O system Table 3- 2 Basic components of the ET 200SP Basic component Function Figure Mounting rail in accord- The mounting rail is the rack of the ET 200SP. ance with EN 60715 The ET 200SP is installed on the mounting rail. - Page 26 System overview 3.4 Components Basic component Function Figure Communication module The communication module CM DP CM DP Connects the CPU with PROFIBUS DP • The bus connection is an RS485 interface • Interface module for The interface module: PROFINET IO Can be used as IO device on PROFINET IO •...

- Page 27 System overview 3.4 Components Basic component Function Figure BusAdapter The BusAdapters allow free selection of the connection technology for PROFINET IO. The following versions are available for PROFINET CPU/interface modules: For standard RJ45 connector (BA 2×RJ45) • ① For direct connection of the bus cable •...

- Page 28 System overview 3.4 Components Basic component Function Figure BaseUnit The BaseUnits provide the electrical and me- chanical connection of the ET 200SP modules. Place the I/O modules or the motor starter onto the BaseUnits. Suitable BaseUnits are available in each case for the different requirements.

- Page 29 System overview 3.4 Components Basic component Function Figure Fail-safe power module The fail-safe power module allows the safety- related shutdown of digital output modules / fail- safe digital output modules. I/O module / fail-safe The I/O module determines the function at the I/O module terminals.

- Page 30 System overview 3.4 Components Basic component Function Figure Vale terminal AirLINE Basic component: SP type 8647 (Bürkert Valve terminal AirLINE SP type 8647 (Bürkert). GmbH & Co. KG) 1) 2) For more information on the AirLINE SP, type 8647 (e.g. data sheet and operating instruc- tions), please contact Bürkert (https://www.burkert.co.uk/en/type/8647) direct- Function:...

- Page 31 Responsibility for these supplementary products and for the information relating to them that is provided here thus lies solely with the third parties in question. Unless bound to do so by statutory requirements, Siemens shall not accept any liability or provide any guarantee for the supplementary products of third-party firms. Please also note the information "Disclaimer/Use of hyperlinks".

- Page 32 System overview 3.4 Components Accessories of the ET 200SP distributed I/O system Table 3- 3 Accessories of the ET 200SP Accessories Function Figure 24 V DC connector Applying the 24 V DC supply at the connector and connection with the CPU/interface module, for exam- ple.

- Page 33 System overview 3.4 Components Accessories of the SIMATIC ET 200SP motor starters Table 3- 4 SIMATIC ET 200SP motor starter accessories Accessories Function Figure 3DI/LC module The optional 3DI/LC module has three digital inputs and one LC input. For reasons of operational safety, input LC is per- manently set to manual local mode.

-

Page 34: Application Planning

"BU: A0, A1". Note You will find a complete overview of the possibilities of combining BaseUnits and I/O modules /motor starters in the Product information for documentation of the ET 200SP I/O system (http://support.automation.siemens.com/WW/view/en/73021864). Distributed I/O system System Manual, 09/2019, A5E03576849-AJ... - Page 35 Application planning Table 4- 1 Selecting a suitable BaseUnit for I/O modules Selecting a BaseUnit I/O module Examples of suitable I/O modules for BU types (example) I/O module (example) BaseUnit BU type A0 Digital, fail-safe, DI 16×24VDC ST BU15-P16+A0+2D technology or com- See Digital, fail-safe, (6ES7131-6BH00-0BA0) (6ES7193-6BP00-0DA0)

- Page 36 Application planning Selecting a BaseUnit I/O module Examples of suitable I/O modules for BU types (example) I/O module (example) BaseUnit BU type C1 F-CM AS-i Safety ST F-CM AS-i Safety ST BU20-P6+A2+4B (3RK7136-6SC00-0BC1) (BU..B, dark-colored (6ES7193-6BP20-0BC1) BaseUnit) 6ES7...C1 • Up to 30 V DC •...

- Page 37 Application planning Table 4- 2 BaseUnit for motor starters Selecting the BaseUnit BU-30- BU-30- BU-30- BU-30- BU-30- BU-30- BU-30- BU-30- BU-30- BU-30- MS10 24 V infeed 500 V infeed F-DI terminals (no routing of the F-DI signal possible) F-DI infeed F-DI routing Motor starters DS 0.1 -...

- Page 38 Additional information on the functional assignment of the terminals and on the associated BaseUnits can be found in one of the following manuals: ● Manual for the relevant I/O module (http://support.automation.siemens.com/WW/view/en/55679691/133300) ● Manual BaseUnits (http://support.automation.siemens.com/WW/view/en/59753521) ● Motor starter (https://support.industry.siemens.com/cs/ww/en/view/109479973) manual Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

-

Page 39: Selecting The Baseunit For I/O Modules

Application planning 4.1 Selecting the BaseUnit for I/O modules Selecting the BaseUnit for I/O modules 4.1.1 Digital, fail-safe, communication, technology or analog modules without temperature measurement Selection of a suitable BaseUnit ① Light-colored BaseUnit: Configuration of a new potential group, electrical isolation from adjacent module on the left. The first BaseUnit of the ET 200SP is usually a light-colored BaseUnit for feeding the supply voltage L+. -

Page 40: Analog Modules With Temperature Measurement

Application planning 4.1 Selecting the BaseUnit for I/O modules 4.1.2 Analog modules with temperature measurement Selection of a suitable BaseUnit ① Light-colored BaseUnit: Configuration of a new potential group, electrical isolation from adja- cent module on the left. The first BaseUnit of the ET 200SP is usually a light -colored BaseUnit for feeding the supply voltage L+. -

Page 41: Selecting Motor Starters With A Suitable Baseunit

Application planning 4.2 Selecting motor starters with a suitable BaseUnit Selecting motor starters with a suitable BaseUnit 4.2.1 Selecting a BaseUnit for motor starters The motor starter BaseUnits "BU30-MS1", "BU30-MS2", "BU30-MS3" and "BU30-MS4" are compatible with all non-fail-safe motor starters. The motor starter BaseUnits "BU30-MS1", "BU30-MS2", "BU30-MS3", "BU30-MS4", "BU30-MS5", "BU30-MS6", "BU30-MS7", "BU30- MS8", "BU30-MS9"... - Page 42 Application planning 4.2 Selecting motor starters with a suitable BaseUnit Selection criteria for the BaseUnit The figure below shows the criteria you use to select the appropriate BaseUnit: Form separate potential groups on the infeed bus for single-phase (L, N, PE) and three- phase (L1, L2, L3, PE) operation.

-

Page 43: Selecting The Motor Starter

Application planning 4.2 Selecting motor starters with a suitable BaseUnit 4.2.2 Selecting the motor starter You select the suitable motor starter using the load type according to the following scheme: Distributed I/O system System Manual, 09/2019, A5E03576849-AJ... -

Page 44: Selecting Accessories For Motor Starters

Application planning 4.2 Selecting motor starters with a suitable BaseUnit 4.2.3 Selecting accessories for motor starters Observe the installation conditions of the station with ET 200SP motor starters. The figure below shows the criteria the station must meet: Distributed I/O system System Manual, 09/2019, A5E03576849-AJ... -

Page 45: Selecting Potential Distributor Modules

Application planning 4.3 Selecting potential distributor modules Selecting potential distributor modules 4.3.1 Selecting a PotDis-BaseUnit Selection of a suitable PotDis-BaseUnit potential distributor module ① Light-colored PotDis-BaseUnit: Configuration of a new potential group, electrical isolation from adjacent module on the left. The first BaseUnit of the ET 200SP is usually a light-colored Ba- seUnit for the incoming supply voltage. - Page 46 GSD, always use an dummy module; with GSDML, integrate a free space. Additional information Additional information on the potential distributor modules (PotDis-BaseUnits and PotDis- TerminalBlocks) is available in the BaseUnits (http://support.automation.siemens.com/WW/view/en/59753521) manual. Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

-

Page 47: Selecting A Potdis-Terminalblock

18th terminal is used for infeed) for supply of ex- connection to a voltage bus of the PotDis- ternal consumers BaseUnit Additional information Additional information on the potential distributor modules (PotDis-BaseUnits and PotDis- TerminalBlocks) is available in the BaseUnits (http://support.automation.siemens.com/WW/view/en/59753521) manual. Distributed I/O system System Manual, 09/2019, A5E03576849-AJ... -

Page 48: Hardware Configuration

Properties Rule Number of modules Maximum of 12/30/32/64 I/O modules (depending on the CPU used/the interface module used; see CPU (http://support.automation.siemens.com/WW/view/en/90466439/1333 00) and interface module (http://support.automation.siemens.com/WW/view/en/55683316/1333 00) manuals) For every 6 F-modules F-RQ 1x24VDC/24..230VAC/5A (6ES7136- 6RA00-0BF0), the maximum configuration is reduced by 1 module. - Page 49 * 1.125) infeed bus n = number of motor starters of a potential group on the infeed bus Refer to the Manual (https://support.industry.siemens.com/cs/ww/en/view/109479973) for details of how to assign the basic rated operational current I parameter. The following values apply for the potential group of the AC infeed: ●...

-

Page 50: Forming Potential Groups

Application planning 4.5 Forming potential groups Forming potential groups 4.5.1 Basics Introduction Potential groups for the ET 200SP distributed I/O system are formed by systematically arranging the BaseUnits. Requirements For formation of potential groups, the ET 200SP distinguishes between the following BaseUnits: ●... - Page 51 Application planning 4.5 Forming potential groups Placement and grouping of I/O modules Each BaseUnit BU...D that you install in the ET 200SP configuration opens a new potential group and supplies all subsequent I/O modules (on BaseUnits BU...B) with the necessary supply voltage.

- Page 52 Application planning 4.5 Forming potential groups Placement and grouping of I/O modules and motor starters For the potential group (L+/M), the following slot rules apply within the motor starter modules and other I/O modules of the ET 200SP: ● An unassembled BaseUnit (BaseUnit with BU cover) must be inserted between the CPU, an interface module or an I/O module and the motor starter.

- Page 53 ● Maximum current carrying capacity (at 60 °C ambient air temperature): 10 A ● Permissible voltage: Depending on the BaseUnit type (see BaseUnit manual (http://support.automation.siemens.com/WW/view/en/59753521)) Note The AUX potential must always be identical to the potential group of the supply voltage if it is not being used as PE.

- Page 54 Application planning 4.5 Forming potential groups Operating principle CPU/interface module Server module BaseUnit BU...D Self-assembling voltage buses P1/P2 BaseUnit BU...B AUX bus Potential group 1 Infeed bus 500 V AC (L1, L2(N), L3, PE) Potential group 2 Supply voltage L+ Potential group 3 Supply voltage L+ (3) BaseUnit BU...B with dummy module...

-

Page 55: Forming Potential Groups With Baseunit Type B1

Application planning 4.5 Forming potential groups 4.5.2 Forming potential groups with BaseUnit type B1 Introduction The AC I/O modules of the ET 200SP are required to connect sensors/actuators with alternating voltage 24 to 230 V AC. Requirements BaseUnits BU20-P12+A0+4B (BU type B1) and ●... -

Page 56: Forming Potential Groups With Fail-Safe Modules

Application planning 4.5 Forming potential groups ① CPU/interface module ② 24 V DC potential group ③ BaseUnits with DC I/O modules ④ BaseUnits BU 20-P12+A0+4B with AC I/O modules ⑤ Direct voltage ⑥ Alternating voltage Figure 4-5 Placing the BaseUnits for the AC I/O modules 4.5.3 Forming potential groups with fail-safe modules Introduction... - Page 57 Application planning 4.5 Forming potential groups Example of an ET 200SP configuration with fail-safe and non-fail-safe modules In principle, it is not necessary to operate fail-safe and non-fail-safe modules in separate potential groups. You can divide the modules into fail-safe and non-fail-safe potential groups and install them.

-

Page 58: Forming Potential Groups With Motor Starters

The infeed bus has the following properties: ● The infeed bus is assembled by lining up the motor starter BaseUnits "BU30-MSx". ● The infeed bus distributes the energy to the SIMATIC ET 200SP motor starter within one load group. ● You can open load groups by plugging in a 500 V infeed BaseUnit (BU30-MS1, BU30- MS2, BU30-MS5, BU30-MS7 or BU30-MS8). - Page 59 Pay attention to the derating values depending on the configuration. The AUX1 bus is not supported in the BaseUnits of the SIMATIC ET 200SP motor starters. The AUX1 bus is used in ET 200SP motor starters for routing the F-DI signal in BU30-MS7 to BU30-MS10.

-

Page 60: Configuration Examples For Potential Groups

Application planning 4.6 Configuration examples for potential groups Configuration examples for potential groups 4.6.1 Configuration examples with BaseUnits Table 4- 5 Configuration examples with BaseUnits BaseUnits Configuration BU15- P16+A0+2D BU15- P16+A0+2B BU15- P16+A0+2D BU15- P16+A0+2B BU20- P12+A0+0B Distributed I/O system System Manual, 09/2019, A5E03576849-AJ... - Page 61 Application planning 4.6 Configuration examples for potential groups BaseUnits Configuration BU15- P16+A10+2D BU15- P16+A10+2B Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

-

Page 62: Configuration Examples With Potential Distributor Modules

Application planning 4.6 Configuration examples for potential groups 4.6.2 Configuration examples with potential distributor modules 3-wire connection The potential distributor modules allow for a space-saving design. For a 3-wire connection, you can, for example, replace two digital input modules with 8 channels on a 141 mm long BaseUnit with a digital input module with 16 channels and a potential distributor module, each of which is only 117 mm long. - Page 63 Application planning 4.6 Configuration examples for potential groups Supply of external components Another application of the potential distributor modules is the supply of potentials for external components. Potential distributor modules enable simple, compact, integrated and clear design. Observe the current carrying capacity of each terminal: max. 10 A. Figure 4-8 Example: Supply of external components Distributed I/O system...

-

Page 64: Installation

Installation Basics Introduction All modules of the ET 200SP distributed I/O system are open equipment. This means you may only install the ET 200SP distributed I/O system in housings, cabinets or electrical operating rooms and in a dry indoor environment (degree of protection IP20). The housings, cabinets and electrical operating rooms must guarantee protection against electric shock and spread of fire. - Page 65 Installation 5.1 Basics Mounting rail Mount the ET 200SP distributed I/O system on a mounting rail in accordance with EN 60715 (35 × 7.5 mm or 35 × 15 mm). You need to ground the mounting rail separately in the control cabinet. Exception: If you install the rail on grounded, zinc-plated mounting plates, there is no need to ground the rail separately.

- Page 66 Installation 5.1 Basics Minimum clearances The figure below shows the minimum clearances you must observe when installing or dismantling the ET 200SP distributed I/O system. Figure 5-1 Minimum clearances Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

- Page 67 Installation 5.1 Basics General rules for installation WARNING Hazardous Voltage Can Cause Death, Serious Injury, or Property Damage. Hazardous electrical voltage can cause electric shock, burns and property damage. Disconnect your system and devices from the power supply before starting any assembly tasks.

-

Page 68: Installation Conditions For Motor Starters

Installation 5.2 Installation conditions for motor starters Installation conditions for motor starters Observe the following installation conditions when using an ET 200SP motor starter: ● Mounting position You can fit the motor starter vertically or horizontally. The mounting position refers to the alignment of the mounting rail The maximum permissible ambient temperature range depends on the mounting position: –... - Page 69 Note the following mounting rules: Use the following dummy module on the standard mounting rail between the previous module and the SIMATIC ET 200SP motor starter: BU cover 15 mm: 6ES7133-6CV15-1AM0 with BaseUnit 6ES7193-6BP00-0BA0 For operation of the ET 200SP station with an unused BaseUnit, a cover must be provided for the open BaseUnit plug contacts (power connector, power bus connector, and backplane bus connector).

-

Page 70: Mounting The Cpu/Interface Module

Installation 5.3 Mounting the CPU/interface module NOTICE Ensure interference immunity You must not plug any other module into the BaseUnit of the dummy module, otherwise interference immunity is no longer ensured. Mounting the CPU/interface module Introduction The CPU/the interface module connects the ET 200SP distributed I/O system to the fieldbus and exchanges the data between the higher-level control system and the I/O modules / motor starters. - Page 71 Installation 5.3 Mounting the CPU/interface module Mounting the CPU/interface module Watch the video sequence (http://support.automation.siemens.com/WW/view/en/95886218) To install a CPU/interface module, follow these steps: 1. Install the CPU/interface module on the mounting rail. 2. Swivel the CPU/interface module towards the back until you hear the mounting rail release button click into place.

-

Page 72: Installing The Cm Dp Communication Module

Installation 5.4 Installing the CM DP communication module Installing the CM DP communication module Introduction You need the CM DP communication module to use the CPU with a DP master or DP slave. Requirements ● The mounting rail is fitted. ●... - Page 73 Installation 5.4 Installing the CM DP communication module Removing a CM DP The CPU and the CM DP are wired and BaseUnits are located to its right. To remove the CM DP communication module, follow these steps: 1. Switch off the supply voltage on the CPU. 2.

-

Page 74: Mounting Baseunits For I/O Modules

3 to 3.5 mm screwdriver (only for dismantling the terminal box and the encoding element) Installing a BaseUnit Watch "Install configuration" video sequence (http://support.automation.siemens.com/WW/view/en/95886218) To install a BaseUnit, follow these steps: 1. Hook the BaseUnit onto the mounting rail. 2. Swivel the BaseUnit backwards until you hear it click into place on the mounting rail. - Page 75 Installation 5.5 Mounting BaseUnits for I/O modules Removing a BaseUnit WARNING Hazardous Voltage Hazardous electrical voltage can cause electric shock, burns and property damage. Disconnect your system and devices from the power supply before starting any assembly tasks. To remove a BaseUnit, follow these steps: The BaseUnit is wired and there are other BaseUnits to its right and left.

- Page 76 Installation 5.5 Mounting BaseUnits for I/O modules To remove a BaseUnit, follow these steps: 1. Switch off all supply voltages on the ET 200SP distributed I/O system. 2. Loosen the wiring on the BaseUnit (with a 3 to 3.5 mm screwdriver). 3.

-

Page 77: Mounting And Dismantling Baseunits For Motor Starters

"Mounting the mechanical bracket for the BaseUnit (Page 82)". CAUTION Protection against electrostatic charge When handling and installing the SIMATIC ET 200SP motor starter, ensure protection against electrostatic charging of the components. Changes to the system configuration and wiring are only permissible after disconnection from the power supply. - Page 78 Installation 5.6 Mounting and dismantling BaseUnits for motor starters 3. Slide the individual BaseUnits to the left to the previous BaseUnit until they audibly engage. Assemble the BaseUnits only on the DIN rail. Note The BaseUnits for motor starters can be plugged together with the BaseUnits for I/O modules.

-

Page 79: Installing Potential Distributor Modules

Installation 5.7 Installing potential distributor modules Installing potential distributor modules Introduction You use the potential distributor module to distribute a variety of potentials (P1, P2). Requirements The mounting rail is installed. Installing and uninstalling PotDis-BaseUnit You install/uninstall PotDis-BaseUnits as you would the BaseUnits for I/O modules. You can find additional information in section Mounting BaseUnits for I/O modules (Page 73). -

Page 80: Installing The Server Module

The last BaseUnit is mounted. Installing the server module Watch "Install configuration" video sequence (http://support.automation.siemens.com/WW/view/en/95886218) Proceed as follows to install a server module: 1. Hook the server module onto the mounting rail to the right of the last BaseUnit. 2. Swivel the server module backwards on the mounting rail. -

Page 81: Mounting Further Accessories For Motor Starters

Mounting further accessories for motor starters 5.9.1 Mounting the cover for the 500 V AC infeed bus Introduction The 500 V infeed bus connects all SIMATIC ET 200SP motor starters. For finger-safe termination of the infeed bus, you must use the cover. DANGER Hazardous Voltage Can Cause Death, Serious Injury, or Property Damage. - Page 82 5.9 Mounting further accessories for motor starters Procedure Proceed as follows to mount the infeed bus cover on a SIMATIC ET 200SP motor starter: 1. Press the cover onto the opening of the BaseUnit on the right until it audibly engages.

-

Page 83: Mounting The Mechanical Bracket For The Baseunit

Installation 5.9 Mounting further accessories for motor starters 5.9.2 Mounting the mechanical bracket for the BaseUnit Introduction To achieve higher stability, you can use a mechanical bracket on 7.5 mm and 15 mm mounting rails. You must use the mechanical bracket in the following situations: ●... - Page 84 Installation 5.9 Mounting further accessories for motor starters Procedure To mount the mechanical bracket, proceed as follows: 1. Insert the mechanical bracket into the opening at the bottom of the BaseUnit. You use the same mechanical bracket for both mounting rails, rotated through 180° respectively.

- Page 85 Installation 5.9 Mounting further accessories for motor starters The figures below show the mechanical bracket after installation on a 7.5 mm or 15 mm mounting rail. Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

-

Page 86: Mounting The Bu Cover

Failure to do so will result in the danger of electric shock. Procedure To mount the BU cover onto a SIMATIC ET 200SP motor starter, insert the BU cover in the BaseUnit in parallel until both interlocks audibly engage. Distributed I/O system... -

Page 87: Wiring

Wiring Rules and regulations for operation Introduction When installing the ET 200SP distributed I/O system as part of a plant or system, special rules and regulations need to be adhered to depending on the area of application. This section provides an overview of the most important rules that must be observed for the integration of the ET 200SP distributed I/O system in a plant or system. - Page 88 ● For signal and bus lines, you must ensure that a wire/cable break or a cross-circuit does not lead to undefined states of the plant or system. Reference You can find more information in the Designing interference-free controllers (http://support.automation.siemens.com/WW/view/en/59193566) function manual. Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

-

Page 89: Additional Rules And Regulations For The Operation Of The Et 200Sp With Fail-Safe Modules

Wiring 6.2 Additional rules and regulations for the operation of the ET 200SP with fail-safe modules Additional rules and regulations for the operation of the ET 200SP with fail-safe modules 6.2.1 Safety extra-low voltage (SELV, PELV) for failsafe modules and failsafe motor starters WARNING The failsafe modules must be operated with safety extra-low voltage (SELV, PELV). -

Page 90: Requirements For Sensors And Actuators For Fail-Safe Modules And Fail-Safe Motor Starters

Wiring 6.2 Additional rules and regulations for the operation of the ET 200SP with fail-safe modules 6.2.2 Requirements for sensors and actuators for fail-safe modules and fail-safe motor starters General requirements for sensors and actuators Note the following important warning regarding safety-related use of sensors and actuators: WARNING Note that instrumentation with sensors and actuators bears a considerable safety responsibility. - Page 91 Wiring 6.2 Additional rules and regulations for the operation of the ET 200SP with fail-safe modules Additional requirements for sensors for fail-safe motor starters Only single-channel sensors that fulfill the required safety category themselves may be connected to the fail-safe motor starter's F-DI. Fail-safe laying must be observed in accordance with the required safety category.

-

Page 92: Crosstalk Of Digital Input/Output Signals

Wiring 6.2 Additional rules and regulations for the operation of the ET 200SP with fail-safe modules Additional requirements for actuators The fail-safe output modules test the outputs at regular intervals. The F-module briefly switches off the activated outputs and, if necessary, switches on the deactivated outputs. You can assign the maximum duration of the test pulses (dark and light period) with parameters. -

Page 93: Additional Rules And Instructions For Operation With Motor Starters

WARNING Hazardous Voltage at the Motor Can Cause Death, Serious Injury, or Property Damage. Following a short-circuit, the SIMATIC ET 200SP motor starter is defective. Replace the motor starter following a short-circuit. Operating the ET 200SP on grounded incoming supply... - Page 94 Wiring 6.4 Operating the ET 200SP on grounded incoming supply Grounded extra-low voltage (PELV in accordance with IEC 61131-2 or IEC 61010-2-201) Load power supplies/power supply modules with grounded 24 V DC output voltage require safe connection to the protective conductor and voltage limiting (extra low voltage). According to IEC 61131-2 and IEC 61010-2-201, this protection is referred to as PELV (Protective Extra Low Voltage).

- Page 95 Wiring 6.4 Operating the ET 200SP on grounded incoming supply Cable temperature measurement threshold Note Cable temperature measurement threshold When choosing a cable, remember that the cable temperature in operation can be up to 30 °C higher than the ambient temperature of the ET200SP system (example: at an ambient temperature of 60 °C, a connection conductor must be dimensioned for a temperature range of at least 90 °C).

- Page 96 Wiring 6.4 Operating the ET 200SP on grounded incoming supply ET 200SP in the overall configuration The figure below shows the overall configuration of the ET 200SP distributed I/O system (load current supply and grounding concept) with supply from a TN-S network. ①...

-

Page 97: Electrical Configuration Of The Et 200Sp

Wiring 6.5 Electrical configuration of the ET 200SP Electrical configuration of the ET 200SP Electrical isolation Electrical relationships With the ET 200SP distributed I/O system, there is electrical isolation between: ● The load circuits/process and all other circuit components of the ET 200SP distributed I/O system. - Page 98 Wiring 6.5 Electrical configuration of the ET 200SP Figure 6-3 Electrical relationships for ET 200SP with interface module (using IM 155-6 PN ST as an example) Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

-

Page 99: Wiring Rules

Wiring 6.6 Wiring rules Wiring rules Wiring rules for the CPU/interface module and BaseUnits for I/O modules Wiring rules for ... CPU/interface module (supply BaseUnits voltage) (push-in terminal) Permitted cable cross-sections of solid cables (Cu) 0.2 to 2.5 mm : 24 to 13 Permitted cable Without end sleeve 0.2 to 2.5 mm... - Page 100 Wiring 6.6 Wiring rules TWIN end sleeves for the cables of the I/O modules' push-in terminals Due to the space required by TWIN end sleeves with 0.75 mm cross-section, you must ensure a correct angle for the cable arrangement when crimping the TWIN end sleeve so that the cables are optimally arranged.

- Page 101 6.6 Wiring rules Line protection The line protection of the SIMATIC ET 200SP motor starter is provided for the motor outgoing feeder cable when the following condition is met: The cross-section of the motor outgoing feeder cable must be dimensioned for the load ratios of the motor and for the cable-laying method.

-

Page 102: Wiring Baseunits For I/O Modules

Wiring 6.7 Wiring BaseUnits for I/O modules Wiring BaseUnits for I/O modules Introduction The BaseUnits connect the ET 200SP distributed I/O system to the process. The following versions of the BaseUnits can be used: ● BaseUnits (with light-colored terminal box) for opening a potential group: BU..D ●... - Page 103 Tool-free connection of cables: single-wire without wire end ferrule, multi-wire (stranded) with wire end ferrule or ultrasonically sealed Watch the video sequence (http://support.automation.siemens.com/WW/view/en/95886218) To connect a wire without tools, follow these steps: 1. Strip 8 to 10 mm of the wires.

-

Page 104: Connecting Cable Shields For I/O Modules

Wiring 6.8 Connecting cable shields for I/O modules Removing wires Using the screwdriver, press the spring release of the terminal as far as it will go and pull out the wire. Note When you press the spring release, you should not pull on the wire/cable at the same time. This prevents you from damaging the terminal. - Page 105 ● Stripping tool Procedure Watch the "Wiring BaseUnits" video sequence (http://support.automation.siemens.com/WW/view/en/95886218) To connect the cable shield, follow these steps: 1. If necessary, connect the supply voltage L+ and ground to the BaseUnit. 2. Press the shield contact up into the mount until you hear it click into place.

-

Page 106: Wiring Baseunits For Motor Starters

Wiring 6.9 Wiring BaseUnits for motor starters Wiring BaseUnits for motor starters Introduction The following versions of BaseUnits can be used: ● BU30-MS1 (with 24 V DC and 500 V AC infeed) ● BU30-MS2 (with 500 V AC infeed) ● BU30-MS3 (with 24 V DC infeed) ●... - Page 107 Wiring 6.9 Wiring BaseUnits for motor starters The following figure shows an example of a BaseUnit BU30-MS5 (with the maximum number of terminals): ① Push-in terminal ② Spring release Figure 6-9 Terminals on a BaseUnit BU30-MS5 DANGER Hazardous Voltage Can Cause Death, Serious Injury, or Property Damage. Hazardous electrical voltage can cause electric shock, burns and property damage.

- Page 108 5. Check whether or not the conductor is firmly connected by pulling on the cable. Video sequence At the following Internet link, you can see a video about connecting conductors: Wire BaseUnits (http://support.automation.siemens.com/WW/view/en/95886218) Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

- Page 109 Wiring 6.9 Wiring BaseUnits for motor starters Releasing conductors To release a conductor, proceed as follows: 1. Press the screwdriver into the spring release of the terminal until it engages. 2. Pull the conductor out. Note When pressing the spring release, you must not pull on the wire/cable at the same time. In this way, you avoid damaging the terminal.

-

Page 110: Connecting The 3Di/Lc Module For The Motor Starter

6.10 Connecting the 3DI/LC module for the motor starter 6.10 Connecting the 3DI/LC module for the motor starter You will find further information on the 3DI/LC module in the ET 200SP motor starter (https://support.industry.siemens.com/cs/ww/en/view/109479973) manual. Procedure The figure below shows the connections of the 3DI/LC module. ①... - Page 111 Wiring 6.10 Connecting the 3DI/LC module for the motor starter Terminal sketch of the 3DI/LC module The following diagram shows a terminal sketch of the 3DI/LC module: Figure 6-10 Connection example of inputs Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

-

Page 112: Connecting The Supply Voltage To The Cpu/Interface Module

Wiring 6.11 Connecting the supply voltage to the CPU/interface module 6.11 Connecting the supply voltage to the CPU/interface module Introduction The supply voltage of the CPU/interface module is supplied by means of a 4-pin connector plug located on the front of the CPU/interface module. Power supply unit Only use power supply units of type SELV/PELV with safe electrically isolated functional extra low voltage (≤... - Page 113 Tool-free connection of cables: single-wire without end sleeve, multi-wire (stranded) with end sleeve or ultrasonically sealed Watch video sequence: "Connect BusAdapter to the interface module" (http://support.automation.siemens.com/WW/view/en/95886218) To connect a wire without tools, follow these steps: 1. Strip 8 to 10 mm of the wires.

-

Page 114: Connecting Interfaces For Communication

Detailed information on the available BusAdapters and the procedure for connecting PROFINET IO to the CPU/interface module is available in the BusAdapter (https://support.industry.siemens.com/cs/ww/en/view/109751716) manual. 6.12.1 Connecting PROFINET IO (port P3) to the CPU Introduction You use the RJ-45 bus connector to connect PROFINET IO (port P3) directly to the CPU. - Page 115 Wiring 6.12 Connecting interfaces for communication Procedure Insert the RJ45 bus connector into the PROFINET port (port P3) on the CPU. Note Cable support and strain relief If you are using a FastConnect RJ45 bus connector with 90° cable outlet (6GK1901-1BB20- 2AA0), we recommend you provide strain relief for the PROFINET connecting cable.

-

Page 116: Connecting The Profibus Dp Interface To The Interface Module/Communications Module Cm Dp

Wiring 6.12 Connecting interfaces for communication 6.12.2 Connecting the PROFIBUS DP interface to the interface module/communications module CM DP Introduction Using the bus connector (RS485), connect the PROFIBUS DP to the interface module/communications module CM DP. Required tools 3 to 3.5 mm screwdriver Procedure To connect the PROFIBUS DP interface to the interface module / DP communication module CM DP, follow these steps:... -

Page 117: Inserting I/O Modules / Motor Starters And Bu Covers

6.13 Inserting I/O modules / motor starters and BU covers Reference You can find additional information on the PROFIBUS FastConnect bus connector in the corresponding product information on the Internet (http://support.automation.siemens.com/WW/view/en/58648998). 6.13 Inserting I/O modules / motor starters and BU covers Introduction ●... - Page 118 6.13 Inserting I/O modules / motor starters and BU covers Plugging in I/O modules and BU covers Watch video sequence: "Insert I/O modules" (http://support.automation.siemens.com/WW/view/en/95886218) Insert the I/O module or BU cover parallel into the BaseUnit until you hear both latches click into place.

-

Page 119: Mounting/Disassembly Of Motor Starters

Mounting the fan Procedure Proceed as follows to mount a fan on a SIMATIC ET 200SP motor starter: 1. Slide the fan onto the motor starter until you can hear the fan engage. Observe the blowing direction of the fan when mounting. The air stream must be directed to the inside of the motor starter. -

Page 120: Mounting/Disassembly Of Motor Starters

Changes to the system configuration and wiring are only permissible after disconnection from the power supply. To assemble a SIMATIC ET 200SP motor starter, proceed as follows: ● Position the mechanical interlock of the SIMATIC ET 200SP motor starter in the ② assembly/disassembly position ●... - Page 121 The motor starter is firmly locked in the BaseUnit, and all electrical contacts are connected. ② Assembly/disassembly position All electrical contacts are open, and you can use the SIMATIC ET 200SP motor starter in the BaseUnit, or you can remove it from the BaseUnit. ③...

-

Page 122: 3Di/Lc Module

Wiring 6.14 Mounting/disassembly of motor starters To connect the assembly, mount the server module after the last BaseUnit. Note Server module You can find out how to assemble/disassemble the server module in chapter "Installing the server module (Page 79)". Note Removing the motor starter You will find out how to remove the motor starter in chapter "Replacing a motor starter (Page 239)". - Page 123 Wiring 6.14 Mounting/disassembly of motor starters Assembly WARNING Risk of injury from automatic restart When you mount the the 3DI/LC module, the motor starter can switch on autonomously if an ON command (DI1 to DI3) is active. This can result in property damage or serious injury caused by connected devices that are automatically started up.

- Page 124 Wiring 6.14 Mounting/disassembly of motor starters The figure below shows a motor starter with a mounted 3DI/LC module. Disassembly Proceed as follows to remove a 3DI/LC module from a motor starter: 1. Push the release lever on the rear of the 3DI/LC module. ①...

-

Page 125: Labeling Et 200Sp

Wiring 6.15 Labeling ET 200SP 6.15 Labeling ET 200SP 6.15.1 Factory markings Introduction For better orientation, the ET 200SP is equipped with various markings ex factory, which help in the configuration and connection of the modules. Factory markings ● Module labeling ●... - Page 126 Wiring 6.15 Labeling ET 200SP ● Color coding of the potential group – Opening the potential group: Light-colored terminal box and light-colored mounting rail release button – Further conduction of the potential group: Dark-colored terminal box and dark-colored mounting rail release button ●...

-

Page 127: Optional Markings

The following versions of color coded labels are available: ● Module-specific color combinations for the process terminals (see the device manuals I/O modules (http://support.automation.siemens.com/WW/view/en/55679691/133300)). The different colors have the following meaning: Gray = input or output signal, red = potential +, blue = ground. -

Page 128: Applying Color Identification Labels

Wiring 6.15 Labeling ET 200SP Labeling strips The labeling strips can be inserted in the CPU/interface module, I/O module and BU cover and allow identification of the ET 200SP distributed I/O system. The labeling strips can be ordered on a roll for thermal transfer printers or as DIN A4 format sheets for laser printers. ①... - Page 129 ① Module-specific color identification labels (15 mm) for the process terminals. You can find addi- tional information in the I/O Module (http://support.automation.siemens.com/WW/view/en/55679691/133300) manual. ② Color identification labels (15 mm) for the 10 AUX terminals ③ Color identification label (15 mm) for the 10 add-on terminals ④...

-

Page 130: Applying Labeling Strips

Check that the color-coded labels/wiring is correct before commissioning the plant. 6.15.4 Applying labeling strips Procedure Watch video sequence: "Labeling" (http://support.automation.siemens.com/WW/view/en/95886218) Proceed as follows to install a labeling strip: 1. Label the strips. 2. Insert the labeling strip into the interface module or I/O module. Distributed I/O system... -

Page 131: Applying Reference Identification Labels

Applying reference identification labels Procedure Watch video sequence: "Labeling" (http://support.automation.siemens.com/WW/view/en/95886218) Proceed as follows to install a reference identification label: 1. Break off the reference identification labels from the sheet. 2. Insert the reference identification labels into the opening on the CPU/interface module, BusAdapter, BaseUnit, I/O module and PotDis-TerminalBlock. -

Page 132: Configuring

Configuring Configuring ET 200SP Introduction The ET 200SP distributed I/O system is configured and assigned parameters with STEP 7 (CPU/interface module, I/O modules, motor starter and server module) or using configuration software of a third-party manufacturer (interface module, I/O modules, motor starter and server module). - Page 133 V2.3. The GSD file can be installed in the TIA Portal and used without restrictions. Configuring a motor starter You configure SIMATIC ET 200SP motor starters in exactly the same way as the I/O modules of the ET 200SP distributed I/O system. The GSD files can be used with STEP 7 V5.5 SP4 and higher, and TIA Portal V13 SP1 and higher.

- Page 134 If you want to configure F-modules with a GSD file, you need S7-FCT in order to calculate the F_iPar_CRC and assign the PROFIsafe addresses. Additional information can be found on the Internet (https://support.industry.siemens.com/cs/ww/en/view/109763833). You can find S7-FCT on the Internet (https://support.industry.siemens.com/cs/ww/en/view/109762827).

-

Page 135: Configuring The Cpu

Configuring 7.2 Configuring the CPU Configuring the CPU 7.2.1 Reading out the configuration Introduction When a connection to a CPU present in the configuration exists, you use the "Hardware detection" function to read out the configuration of this CPU, including centrally configured modules, and apply it to your project. - Page 136 Configuring 7.2 Configuring the CPU 2. In the device view (or in the network view), select the "Hardware detection" command in the "Online" menu. Figure 7-2 Hardware detection in the Online menu You can also double-click the CPU and click "Detect" in the message. Figure 7-3 Hardware detection message in the device view 3.

- Page 137 Configuring 7.2 Configuring the CPU STEP 7 assigns a valid default parameter assignment for all modules. You can change the parameter assignment subsequently. Note If you want to go online after the hardware detection, you have to first download the detected configuration to the CPU;...

-

Page 138: Addressing

Configuring 7.2 Configuring the CPU 7.2.2 Addressing Introduction In order to address the automation components or I/O modules, they have to have unique addresses. The following section explains the various address areas. I/O address I/O addresses (input/output addresses) are required in the user program to read inputs and set outputs. - Page 139 Configuring 7.2 Configuring the CPU Hardware identifier STEP 7 automatically assigns a hardware identifier to identify and address modules and submodules. You use the hardware identifier in the case of diagnostic messages or operations, for example, to identify a defective module or the module addressed. Figure 7-6 Example of a hardware identifier from STEP 7 In the "System constants"...

-

Page 140: Process Images And Process Image Partitions

Configuring 7.2 Configuring the CPU 7.2.3 Process images and process image partitions 7.2.3.1 Process image - overview Process image of the inputs and outputs The process image input and output is an image of the signal states. The CPU transfers the values from the input and output modules to the process image input and output. -

Page 141: Automatically Updating Process Image Partitions

Configuring 7.2 Configuring the CPU 7.2.3.2 Automatically updating process image partitions You can assign one process image partition to each organization block. In this case, the user program automatically updates the process image partition. The exceptions are PIP 0 and isochronous OBs. - Page 142 This prevents a subsequent output of the process image from again overwriting the value written by direct access. Reference Additional information on process image partitions is available in the function manual, Cycle and response times (http://support.automation.siemens.com/WW/view/en/59193558). Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

-

Page 143: Configuring The Interface Module

The actual configuration can then differ from the specified configuration. For additional information on assigning the F-destination address, refer to the SIMATIC Safety - Configuring and Programming (http://support.automation.siemens.com/WW/view/en/54110126) Programming and S7 Configuration Pack Operating Manual and to the online help for the Distributed I/O system... -

Page 144: Basics Of Program Execution

Basics of program execution Events and OBs Start events The table below gives an overview of the possible event sources for start events and their OBs. Table 8- 1 Start events Types of event sources Possible priorities (default Possible OB num- Default system Number of OBs priority) - Page 145 Basics of program execution 8.1 Events and OBs Types of event sources Possible priorities (default Possible OB num- Default system Number of OBs priority) bers response Programming error (only for 2 to 26 (7) STOP 0 or 1 global error handling) I/O access error (only for 2 to 26 (7) Ignore...

-

Page 146: Asynchronous Instructions

Basics of program execution 8.2 Asynchronous instructions OB priority and runtime behavior If you have assigned an OB to the event, the OB has the priority of the event. The CPU supports the priority classes 1 (lowest priority) to 26 (highest priority). The following items are essential to the processing of an event: ●... - Page 147 Basics of program execution 8.2 Asynchronous instructions Difference between synchronous/asynchronous instructions The figure below shows the difference between processing an asynchronous instruction and processing a synchronous instruction. In this figure the asynchronous instruction is called five times before the execution is completed, for example, a data record is completely transferred.

- Page 148 Basics of program execution 8.2 Asynchronous instructions Parallel processing of asynchronous instruction jobs A CPU can process several asynchronous instruction jobs in parallel. The CPU processes the jobs in parallel under the following conditions: ● Several asynchronous instruction jobs are called at the same time. ●...

- Page 149 Basics of program execution 8.2 Asynchronous instructions Status of an asynchronous instruction An asynchronous instruction shows its status via the block parameters STATUS/RET_VAL and BUSY. Many asynchronous instructions also use the block parameters DONE and ERROR. The figure below shows the two asynchronous instructions WRREC and CREATE_DB. ①...

- Page 150 Basics of program execution 8.2 Asynchronous instructions Summary The table below provides you with an overview of the relationships described above. It shows in particular the possible values of the output parameters if processing is not completed after a call. Note Following every call, you must evaluate the relevant output parameters in your program.

- Page 151 Basics of program execution 8.2 Asynchronous instructions Extended instructions: maximum number of concurrently running jobs Table 8- 2 Maximum number of concurrently running jobs for asynchronous extended instructions and lower-level instruc- tions used Extended instructions CPU 1510SP-1 PN CPU 1512SP-1 PN CPU 1510SP F-1 PN CPU 1512SP F-1 PN Distributed I/O...

- Page 152 Basics of program execution 8.2 Asynchronous instructions Extended instructions CPU 1510SP-1 PN CPU 1512SP-1 PN CPU 1510SP F-1 PN CPU 1512SP F-1 PN WRIT_DBL DELETE_DB File handling FileReadC FileWriteC Basic instructions: maximum number of concurrently running jobs Table 8- 3 Lower-level instructions used for asynchronous basic instructions Basic instructions CPU 1510SP-1 PN...

- Page 153 Basics of program execution 8.2 Asynchronous instructions Table 8- 5 Lower-level instructions used for asynchronous instructions for MODBUS TCP MODBUS TCP CPU 1510SP-1 PN CPU 1512SP-1 PN CPU 1510P F-1 PN CPU 1512SP F-1 PN MB_CLIENT uses TSEND, TUSEND, TRCV, TURCV, TCON, TDISCON MB_SERVER uses TSEND, TUSEND, TRCV, TURCV, TCON, TDISCON Table 8- 6...

- Page 154 Basics of program execution 8.2 Asynchronous instructions Table 8- 8 Maximum number of concurrently running jobs for asynchronous instructions for OPC UA OPC_UA CPU 1510SP-1 PN CPU 1512SP-1 PN CPU 1510SP F-1 PN CPU 1512SP F-1 PN OPC_UA_Connect OPC_UA_Disconnect OPC_UA_NamespaceGetIndexList OPC_UA_NodeGetHandleList OPC_UA_NodeReleaseHandleList OPC_UA_TranslatePathList...

- Page 155 Basics of program execution 8.2 Asynchronous instructions Technology: maximum number of concurrently running jobs Table 8- 9 Maximum number of concurrently running jobs for asynchronous instructions for technology. The instructions for technology use a common pool of resources. Technology CPU 1510SP-1 PN CPU 1510SP F-1 PN CPU 1512SP-1 PN CPU 1512SP F-1 PN...

-

Page 156: Protection

● Deactivation of the OPC UA server (you will find further information on the security mechanisms for OPC UA servers in the Communication (https://support.industry.siemens.com/cs/ww/en/view/59192925) function manual) ● Deactivation of time synchronization via an NTP server ● Deactivation of PUT/GET communication... -

Page 157: Configuring Access Protection For The Cpu

Protection 9.2 Configuring access protection for the CPU Configuring access protection for the CPU Introduction The CPU offers four access levels to limit access to specific functions. By setting up the access levels and the passwords for a CPU, you limit the functions and memory areas that are accessible without entering a password. - Page 158 Protection 9.2 Configuring access protection for the CPU Access levels Access restrictions HMI access With this access level only HMI access and access to diagnostics data are possi- ble without entering the password. Without entering the password, you can neither load blocks nor the hardware configuration into the CPU, nor load blocks and hardware configuration from the CPU into the programming device.

- Page 159 Protection 9.2 Configuring access protection for the CPU Behavior of functions with different access levels The STEP 7 online help includes a table which lists the online functions that are available in the different access levels. Selecting the access levels To configure the access levels of a CPU, follow these steps: 1.

-

Page 160: Using The User Program To Set Additional Access Protection

For additional information on this access level, refer to the description of the fail-safe system SIMATIC Safety Programming and Operating Manual SIMATIC Safety - Configuring and Programming (http://support.automation.siemens.com/WW/view/en/54110126). Using the user program to set additional access protection Access protection via user program You can also restrict access to a password-protected CPU in STEP 7 via the ENDIS_PW operation. -

Page 161: Know-How Protection

Protection 9.4 Know-how protection Know-how protection Application You can use know-how protection to protect one or more OB, FB or FC blocks as well as global data blocks in your program from unauthorized access. Enter a password to restrict access to a block. The password offers high-level protection against unauthorized reading or manipulation of the block. - Page 162 Protection 9.4 Know-how protection Global data blocks and array data blocks You protect global data blocks (global DBs) from unauthorized access with know-how protection. If you do not have the valid password, you can read the global data block but not change it.

- Page 163 Protection 9.4 Know-how protection 6. Click "OK" to confirm your entry. 7. Close the "Know-how protection" dialog by clicking "OK". Result: The selected blocks are now know-how protected. Know-how protected blocks are marked with a lock in the project tree. The password entered applies to all blocks selected. Note Password provider Alternatively, you can set up know-how protection for blocks with a password provider.

- Page 164 Protection 9.4 Know-how protection 4. Enter the password. Figure 9-6 Removing block know-how protection (2) 5. Click "OK" to confirm your entry. Result: Know-how protection is removed from the selected block. See also Copy protection (Page 164) Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

-

Page 165: 9.5 Copy Protection

Protection 9.5 Copy protection Copy protection Application The copy protection allows you to protect your program against unauthorized duplication. With copy protection you associate the blocks with a specific SIMATIC memory card or CPU. Through the linking of the serial number of a SIMATIC memory card or of a CPU the use of this program or of this block is only possible in conjunction with a specific SIMATIC memory card or CPU. - Page 166 Protection 9.5 Copy protection 4. Activate the option "Serial number is inserted when downloading to a device or a memory card" if the serial number is to be inserted automatically during the uploading process (dynamic binding). Assign a password using the "Define password" button to link the use of a block additionally to the input of a password.

-

Page 167: Configuration Control (Option Handling)

Configuration control (option handling) Introduction Configuration control (option handling) is used to operate various standard machine configuration levels in one project without changing the configuration or the user program. Operating principle of configuration control You can use configuration control to operate different standard machine configurations with a single configuration of the ET 200SP distributed I/O system. - Page 168 Configuration control (option handling) The following figure shows three configurations of a standard machine with the corresponding station options of the ET 200SP distributed I/O system. Figure 10-1 Various configuration levels of a standard machine with the corresponding station options of the ET 200SP distributed I/O system. Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

- Page 169 Library for configuration control A library for configuration control is available on the Internet for download (https://support.industry.siemens.com/cs/#document/29430270?lc=en-WW). The library contains data types with the structure of the control data records for the ET 200SP distributed I/O system. You can implement your flexible automation solution inexpensively with the help of these data types.

-

Page 170: Configuring

Configuration control (option handling) 10.1 Configuring 10.1 Configuring Requirements Configuration control is supported by the ET 200SP distributed I/O system with both an ET 200SP CPU and with interface modules via PROFINET IO and PROFIBUS DP. Centrally for ET 200SP CPU: ●... - Page 171 Configuration control (option handling) 10.1 Configuring Required steps Enable the "Allow to reconfigure the device via the user program" parameter when configuring the CPU/interface module in STEP 7 (TIA Portal). ● The "Allow to reconfigure the device via the user program" parameter is located in the "Configuration control"...

-

Page 172: Creating The Control Data Record

Configuration control (option handling) 10.2 Creating the control data record 10.2 Creating the control data record 10.2.1 Introduction Required steps To create a control data record for the configuration control, follow these steps: 1. Create a PLC data type that contains the structure of the control data record. The following figure shows a PLC data type "CTR_REC", which contains the structure of the control data record for an ET 200SP interface module. - Page 173 Configuration control (option handling) 10.2 Creating the control data record 3. In the data block, create an array that is based on the created PLC data type. 4. In the control data records, enter the slot assignments in the "Start value" column. The figure below shows the global data block "ConfDB".

-

Page 174: Control Data Record For An Et 200Sp Cpu

Configuration control (option handling) 10.2 Creating the control data record Using communication modules When configuration control (option handling) is used, you may insert the following communication modules: ● CM DP ● CP 1542SP-1 ● CP 1543SP-1 ● CP 1542SP-1 IRC ●... - Page 175 Configuration control (option handling) 10.2 Creating the control data record Control data record For the configuration control of an ET 200SP CPU, you define a control data record 196 V2.0, which includes a slot assignment. The maximum slot of the configuration corresponds to the slot of the server module or last slot of an ET 200AL I/O module (in a mixed ET 200SP/ET 200AL configuration).

-

Page 176: Control Data Record For An Interface Module

Configuration control (option handling) 10.2 Creating the control data record Byte Element Code Explanation First slot of ET 200AL (slot Slot assignment in the Control element ET 200AL station option Contains information on which ET 200AL module is inserted in which slot. Reserved The value that you need to enter in the corresponding byte depends on the fol-... - Page 177 Configuration control (option handling) 10.2 Creating the control data record Simplified control data record (V1) For the configuration control of interface modules of the ET 200SP distributed I/O system, you define a control data record 196 V1.0, which includes a slot assignment. The maximum slot of the configuration corresponds to the slot of the server module or ET 200AL I/O module (in a mixed ET 200SP / ET 200AL configuration).

- Page 178 Configuration control (option handling) 10.2 Creating the control data record Control data record (V2) If you change the potential groups in the station option compared to the station master, define a control data record 196 V2.0 for the ET 200SP interface module which contains a slot assignment.

- Page 179 Configuration control (option handling) 10.2 Creating the control data record Byte Element Code Explanation 4 + ((first slot First slot ET 200AL Slot assignment in the Control element ET 200AL ET 200AL - 1) x 2) station option Contains information on which ET 200AL module is inserted in which slot.

-

Page 180: Feedback Data Record For Interface Modules

Configuration control (option handling) 10.2 Creating the control data record 10.2.4 Feedback data record for interface modules Operating principle The feedback data record informs you about the accuracy of the module assignment and gives you the option of detecting assignment errors in the control data record. The feedback data record is mapped via a separate data record 197 V2.0. - Page 181 Configuration control (option handling) 10.2 Creating the control data record Feedback data record Table 10- 7 Feedback data record Byte Element Code Explanation Block length 4 + (number of slots x 2) Header Block ID Version Slot 1 status Status = 1: Reserved Module from station master is •...

-

Page 182: Data Records And Functions

Configuration control (option handling) 10.2 Creating the control data record Error messages In case of error, the RDREC instruction returns the following error messages via the STATUS block parameter while reading the feedback data record: Table 10- 8 Error messages Error code Meaning 80B1... -

Page 183: Transferring Control Data Record In The Startup Program Of The Cpu

Configuration control (option handling) 10.3 Transferring control data record in the startup program of the CPU 10.3 Transferring control data record in the startup program of the CPU Required steps Transfer the created control data record 196 to the CPU/the interface module using the instruction WRREC (Write data record) instruction. - Page 184 Configuration control (option handling) 10.3 Transferring control data record in the startup program of the CPU Error messages In case of error, the instruction WRREC returns the following error messages via the STATUS block parameter: Table 10- 9 Error messages Error code Meaning 80B1...

- Page 185 Configuration control (option handling) 10.3 Transferring control data record in the startup program of the CPU Special aspects relating to the transfer of the control data record to the CPU ● If you have enabled configuration control, the CPU is not ready for operation without a control data record.

- Page 186 Configuration control (option handling) 10.3 Transferring control data record in the startup program of the CPU Example in FBD: Use the LABEL (jump label) and JMP (jump at RLO=1) instructions to program a loop. Figure 10-5 WRREC ● The control data record is stored retentively in the CPU. Note: –...

-

Page 187: Behavior During Operation

Configuration control (option handling) 10.4 Behavior during operation Special aspects relating to the transfer of the control data record to the interface module ● If you have enabled configuration control, the ET 200SP station is not ready for operation without a control data record. As long as no valid control data record has been transferred, the I/O modules are considered as failed by the CPU and exhibit substitute value behavior. -

Page 188: Examples Of Configuration Control

Configuration control (option handling) 10.5 Examples of configuration control Inserting modules on empty slots If you replace a BU cover placed on an empty slot with an I/O module when configuration control is enabled, the ET 200SP distributed I/O system behaves as follows: ●... - Page 189 Configuration control (option handling) 10.5 Examples of configuration control Station option 1 with module that is not present The module that is located in slot 3 in the station master is not present in the station option 1. Slot 3 must be designated in the control data record accordingly with 0 (= not present). The server module is located in slot 3 in the station option.

- Page 190 Configuration control (option handling) 10.5 Examples of configuration control Station option 2 with modified order of modules The order of the modules at slots 2 and 3 is interchanged. Figure 10-7 Example: Hardware configuration of station option 2 with the associated control data record in STEP 7 Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

- Page 191 Configuration control (option handling) 10.5 Examples of configuration control Station option 3 with empty slot The module that is located in slot 3 in the station master occupies an empty slot with BU cover in the station option. Enter the value 130 in slot 3 in the control data record. Figure 10-8 Example: Hardware configuration of station option 3 with the associated control data record in STEP 7...

- Page 192 Configuration control (option handling) 10.5 Examples of configuration control Station option 4: Opening a new potential group A new potential group is opened at slot 3 of station option 4. Compared to the station master, a dark-colored BaseUnit is replaced by a light-colored BaseUnit. Enter the value 1 as additional function.

-

Page 193: Commissioning

Also allow for any possible foreseeable errors in the tests. This avoids endangering persons or equipment during operation. PRONETA With SIEMENS PRONETA (PROFINET network analysis), you analyze the system network during commissioning. PRONETA features two core functions: ● The topology overview independently scans PROFINET and all connected components. - Page 194 ● General reset of a CPU's memory ● Resetting devices to factory settings ● Downloading a firmware update to a device ● ... You can find the SIMATIC Automation Tool on the Internet (https://support.industry.siemens.com/cs/ww/de/view/98161300). Distributed I/O system System Manual, 09/2019, A5E03576849-AJ...

-

Page 195: Commissioning The Et 200Sp For Profinet Io

Requirements ● The CPU/interface module is in the "Factory settings" status or has been reset to factory settings (see section Interface module (http://support.automation.siemens.com/WW/view/en/55683316/133300)). ● For CPU: The SIMATIC memory card is as delivered or has been formatted. 11.2.1 ET 200SP CPU as an IO controller... - Page 196 Section Configuring (Page 131) Checking the protective measures Switching on supply voltages for the IO CPU 15xxSP-1 PN controller (http://support.automation.siemens.com/ WW/view/en/90466439/133300) manual Switching on supply voltages for IO devices Documentation of the IO device Downloading the configuration to the IO...

-

Page 197: 200Sp Cpu As An I-Device

Commissioning 11.2 Commissioning the ET 200SP for PROFINET IO 11.2.2 ET 200SP CPU as an I-device Configuration example You need the CPU 151xSP-1 PN to use the ET 200SP distributed I/O system as an I-device. Figure 11-2 ET 200SP CPU as an I-device Distributed I/O system System Manual, 09/2019, A5E03576849-AJ... - Page 198 Documentation of the IO controller controller Switching on supply voltages for I-device CPU 15xxSP-1 PN and IO devices (http://support.automation.siemens.com/ WW/view/en/90466439/133300) manual and documentation of the IO devices Download configuration to the I-device STEP 7 online help Switching IO controller and I-device to RUN...

-

Page 199: Et 200Sp As An Io Device

Switching on supply voltages Documentation of the IO controller for the IO controller Switching on supply voltages Interface module for IO devices (http://support.automation.siemens.com/WW/view/en/5 5683316/133300) Manual Downloading the configura- STEP 7 online help tion to the IO controller Distributed I/O system... -

Page 200: Commissioning The Et 200Sp On Profibus Dp

Switching IO controller to Documentation of the IO controller RUN mode Checking LEDs Interface module (http://support.automation.siemens.com/WW/view/en/5 5683316/133300) Manual Testing inputs and outputs The following functions are helpful: Monitoring and modifying tags, testing with program status, forcing, controlling the outputs. Refer to section Test and ser- vice functions (Page 258) 11.3... - Page 201 Section Removing/inserting a SIMATIC master (CPU) memory card on the CPU (Page 205) Configuring DP master (including CPU 15xxSP-1 PN PROFIBUS address) (http://support.automation.siemens.com/ WW/view/en/90466439/133300) and CM DP manual Switching on supply voltages for DP master CPU 15xxSP-1 PN (http://support.automation.siemens.com/ WW/view/en/90466439/133300) manual...

-

Page 202: 200Sp As I-Slave

Commissioning 11.3 Commissioning the ET 200SP on PROFIBUS DP 11.3.2 ET 200SP as I-slave Configuration example To use the ET 200SP distributed I/O system as I-slave, you need the CPU 151xSP-1 PN and the CM DP communication module. Figure 11-5 ET 200SP as I-slave Distributed I/O system System Manual, 09/2019, A5E03576849-AJ... - Page 203 (CPU) memory card on the CPU (Page 205) Configuring I-slave (including PROFIBUS CPU 15xxSP-1 PN address) (http://support.automation.siemens.com/ WW/view/en/90466439/133300) and CM DP manual Switching on supply voltages for DP master Documentation of the DP master Switching on supply voltages for I-slaves CPU 15xxSP-1 PN (http://support.automation.siemens.com/...

-

Page 204: 200Sp As A Dp Slave

Procedure See ... Installing ET 200SP (with IM 155-6 DP HF) Section Installation (Page 63) Setting the PROFIBUS address on the Section Interface module interface module (http://support.automation.siemens.com/ WW/view/en/55683316/133300) Connecting ET 200SP Section Wiring (Page 86) Supply voltages • PROFIBUS DP •... -

Page 205: Startup Of The Et 200Sp With Empty Slots

11.4 Startup of the ET 200SP with empty slots Step Procedure See ... Checking LEDs Interface module (http://support.automation.siemens.com/ WW/view/en/55683316/133300) Manual Testing inputs and outputs The following functions are helpful: Mon- itoring and modifying tags, testing with program status, forcing, controlling the outputs. -

Page 206: Removing/Inserting A Simatic Memory Card On The Cpu

Commissioning 11.5 Removing/inserting a SIMATIC memory card on the CPU 11.5 Removing/inserting a SIMATIC memory card on the CPU Requirement The CPU only supports pre-formatted SIMATIC memory cards. If necessary, delete all previously stored data before using the SIMATIC memory card. You can find more information on deleting the content of the SIMATIC memory card in the function manual Structure and use of the CPU memory. -

Page 207: Operating Modes Of The Cpu

Reference You can find more information on the SIMATIC memory card in the function manual Structure and use of the CPU memory (https://support.industry.siemens.com/cs/ww/en/view/59193101). 11.6 Operating modes of the CPU Introduction Operating modes describe the status of the CPU. The following operating modes are possible using the mode selector: ●... - Page 208 Commissioning 11.6 Operating modes of the CPU Special features during startup Note the following points regarding the STARTUP mode: ● All outputs are disabled or react according to the parameter settings for the particular I/O module: They provide a substitute value as set in the parameters or retain the last value output and bring the controlled process to a safe operational status.

- Page 209 Commissioning 11.6 Operating modes of the CPU Cancellation of startup If errors occur during startup, the CPU cancels startup and returns to STOP mode. The CPU does not perform the startup or interrupts the startup under the following conditions: ● You have not inserted a SIMATIC memory card or have inserted an invalid one. ●...

-

Page 210: Stop Mode