Summary of Contents for GCE druva LINE 200

- Page 1 FLASCHEN-, LEITUNGS- UND ENTNAHME- DRUCKMINDERER BAUREIHE 200, 500 UND 320 CYLINDER, LINE AND SUPPLY PRESSURE REGULAFORS PRODUCT LINE 200, 500 AND 320 OPERATING INSTRUCTIONS BETRIEBSANLEITUNG Page 1/24...

-

Page 2: Table Of Contents

GENERAL 1.1 CONTENTS 1. General 2. Fundamental safety instructions 3. Storage and transport 4. Technical data 5. Identification 6. Installation, assembly, commissioning 7. Start-up 8. Changing cylinders and ending operation 9. Ending operation 10. Servicing and malfunctions Redelivery 12. This document 1.2 PREFACE These pure gas components are precision instruments of superior quality. - Page 3 2.5 INTENDED USE The pressure device is only to be used for expanding gaseous media from gas cylinders. Any use other than or exceeding this is regarded as improper use. The intended use also encompasses • observing all information in the operating instructions, •...

- Page 4 2.11 SAFETY MEASURES IN NORMAL OPERATION • Before switching on the pressure device, ensure that no-one can be put in a situation of danger due to the pressure device start-up. • Check the pressure device for leaks and correct function of safety equipment at least once annually. 2.12 DANGER FROM ELECTRICITY •...

-

Page 5: Storage And Transport

oily rags or lubricants. Do not clean with solvents. 2.20 NOISE GENERATION In some cases noise generation can result from an unfavourable combination of particular parameters, e.g. flow rate and pressure range, but also gas type. In such cases please contact the manufacturer. 2.21 LAWS, DIRECTIVES, NORMS, REGULATIONS LAWS AND REGULATIONS •... - Page 6 • tightness • electric operating conditions • temperature range. 4.2 PRESSURE REGULATORS PRODUCT LINE 500 A maximum of six (in some cases four) inlet and outlet bores with NPT 1/4” female thread allow a wide range of options for connecting and adapting the pressure regulator.

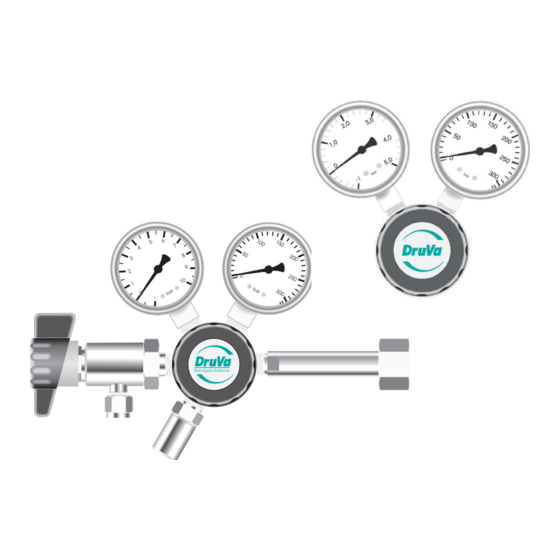

- Page 7 Line pressure regulators are used to reduce a higher tube pressure to a certain low supply pressure level. They remain constantly installed inside the tube system. Pressure regulators LMD 500: 1 Cylinder connection 2 Pressure regulator 3 Inlet pressure gauge 4 Outlet pressure gauge 5 Process gas valve 6 Relief valve...

-

Page 8: Identification

This product line is distinguished by a great reliability, low leakage and longlife endurance. Shut-off valves and metering valves are as well deliverable in straight (G) or angel version (W). MVA 500 G/W SHUT-OFF VALVE The shut-off valve is simple to operate, with 90° turn and click effect. The open/shut position is clearly recognizable: handwheel parallel to gas line –... -

Page 9: Start-Up

PREPARATION Use only cylinder connections appropriate for the type of gases used according to DIN 477. CONNECTION TO THE CYLINDER 1. First screw the union nut onto the cylinder by hand. Pay attention to right- and left-handed threads! Align the regulator. - Page 10 Before switching on the pressure device ensure that no-one can be put in a situation of danger by starting up the pressure device. Use only pressure device with external gas purging when working with toxic, corrosive or pyrophoric gases. PREPARATION Take care that process and purge gas lines are connected gas tight to the appropriate in- and outlets.

-

Page 11: Servicing And Malfunctions En

SERVICING AND MALFUNCTIONS 10.1 MAINTENANCE For reasons of safety, repairs and servicing must only be carried out by the manufacturer or by a specialist firm authorized by the manufacturer, and only using original spare parts. To ensure perfect function and consistent safety, all components of the fittings of a gas supply system should be checked once annually by the manufacturer. - Page 13 GCE Group is one of the world´s leading companies in the field of gas control equipment. The headquarters are in Malmö, Sweden, and the two major supply units are located in Europe and Asia. The company operates 15 subsidiaries around the world and employs more than 850 people.