Summary of Contents for Bosch FW 120

- Page 1 Weather-compensated controller with solar control FW 120 for heating appliances with BUS-enabled Heatronic 3 Installation and operating instructions...

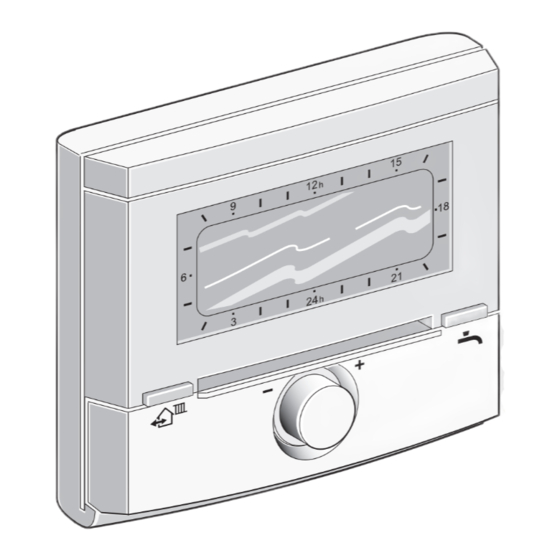

- Page 2 2 | Overview of controls and symbols Overview of controls and symbols advance advance menu info 6 720 617 763-01.1O Fig. 1 Standard display 6 720 800 844 (2012/02)

- Page 3 Overview of controls and symbols | 3 Controls Symbols 1 Turning the rotary selector in + direction: Current room temperature Selects menu/information above or increases (only with wall mounting) setting value Flashing segment: Turning the rotary selector in – direction: Current time (13:45 to 14:00) Selects menu/information below or decreases Solid segments:...

-

Page 4: Table Of Contents

4 | Contents Contents 5.1.3 Changing DHW mode Chapters against a grey background (time-limited) ....19 are intended for installers. The 5.1.4 Changing heating mode permanently . - Page 5 Contents | 5 Menu settings INSTALLER SETTINGS 10 Energy saving tips ....60 (contractors only) ....39 INSTALLER SETTINGS 11 Environmental protection .

-

Page 6: Key To Symbols And Safety Instructions

6 | Key to symbols and safety instructions Key to symbols and safety instructions Additional symbols Explanation of symbols Symbol Explanation Action step Warnings Cross-reference to other parts of this Warnings in this document are framed document or to other documents and identified by a warning triangle List/list entry •... -

Page 7: Safety Instructions

Key to symbols and safety instructions | 7 Safety instructions B These instructions must be observed to ensure correct operation. B Install and commission the heating appliance and all accessories in accordance with the instructions provided. B This accessory must only be installed by suitably qualified installers. -

Page 8: Technical Data For The Accessory Item

8 | Technical data for the accessory item Technical data for the accessory item The FW 120 can only be connected Standard delivery to a heating appliance with BUS- enabled Heatronic 3. This controller is used to display appliance •... -

Page 9: Specification

Technical data for the accessory item | 9 Specification Cleaning B If required, use a damp cloth to wipe the Dimensions Fig. 8, page 13 controller casing. Never use aggressive or Rated voltage 10...24 V DC acidic cleaning agents for this. Rated current 6 mA (excluding illumination) -

Page 10: Sample System

Common flow sensor ISM 1 Module for solar DHW heating DHW connection Cold water connection The FW 120 can be mounted in the Mixer servomotor heat source or on the wall. Flow temperature sensor, mixed Either FB 10 or FB 100... -

Page 11: Installation (For Contractors Only)

Installation (for contractors only) | 11 Installation (for contractors only) The detailed system scheme for installing the DANGER: Risk of electric shock! hydraulic components and associated control devices can be found in the technical guides or B Prior to the installation of this tender documentation. - Page 12 12 | Installation (for contractors only) B Click top section into place and mount cover. 6 720 641 933-32.1O Fig. 7 6 720 800 844 (2012/02)

-

Page 13: Wall Mounting

Installation (for contractors only) | 13 3.1.2 Wall mounting The control quality of the controller is dependent B Fit the base. on where it is installed. The installation location (= lead room) must be suitable for controlling the heating. B Select the installation location. 35 mm 134 mm 0,3 m... -

Page 14: Installation Of Outside Temperature

14 | Installation (for contractors only) 3.1.3 Installation of outside temperature sensor Control quality depends on installation location B Select the installation location. of outside temperature sensor AF. 6 720 645 349-02.1O Fig. 12 6 720 800 844 (2012/02) -

Page 15: Fitting Other Accessories

B Installation of the controller automatically produces BUS connection via the three contacts ( Fig. 6 on page 11). Heatronic 3 FW 120 ST 19 4 B B 6 720 800 004-02.1O Fig. 13 Fig. 14 Controller installed via BUS contacts in BUS-enabled Heatronic 3. -

Page 16: Electrical Connection For Wall

... 1.50 mm radio and television set, amateur radio ≥ 30 m 1.50 mm stations, microwave ovens etc). Tab. 7 Heatronic 3 FW 120 ST 19 4 B B 6 720 800 004-03.1O Fig. 15 Controller connected to BUS-enabled Heatronic 3. -

Page 17: Commissioning (Contractors Only)

Commissioning (contractors only) | 17 Commissioning (contractors only) B Set DIP switch at IPM 1 to 1. B Switch ON the system. B Set FB 10 or FB 100 to 1. Description of the controls page 2. During commissioning or after a global reset (resetting all settings), the language selected for the factory settings will be displayed. -

Page 18: Operation

18 | Operation Operation 5.1.2 Advancing heating mode before the The controller provides the option programmed time (bringing forward the of setting the required room next switching point) temperature for the operating mode To permanently change the operating mode, concerned. The temperature given chapter 5.1.4 on page 19. -

Page 19: Changing Dhw Mode (Time-Limited)

Operation | 19 5.1.3 Changing DHW mode (time-limited) 5.1.4 Changing heating mode permanently You can use this function if you need DHW is heated independently of the hot water outside the programmed position of the operating mode selector switching times. in accordance with the DHW program chapter 6.3 from page 29). -

Page 20: Display Views And Menu Navigation

– can be changed with – can be deleted (reset to the default) with The user interface of the weather- compensation controller FW 120 is implemented as a menu system. Within that menu, the various functions – is stored with are arranged in a hierarchical structure. -

Page 21: Setting Programs

Operation | 21 B Press Setting programs The Heating menu is selected and the title bar shows the current menu name (in this case Setting and changing switching times and HEATING). operating modes Setting programs and switching times always follows the same pattern. In the delivered condition, programmes for heating and DHW heating are already stored in 6 720 800 817-02.1O... - Page 22 22 | Operation B Press to confirm the menu point B Turn until the required operating mode Monday. (e.g. Economy) or temperature is shown. The next submenu (EDIT PROGRAMME The segment ring always shows the effect of MON) showing the programmed switching the change on the heating program.

-

Page 23: Deleting An Individual Switching

Operation | 23 5.3.2 Deleting an individual switching point 5.3.3 Resetting an entire program (overwriting with factory settings) B Place the highlight onto the value to be deleted, as described in chapter , e.g. B Call up menu: Heating > Programme, parameter P1 (= switching point 1). -

Page 24: Resetting All Settings (For Heating Contractors Only)

24 | Operation Resetting all settings (for heating contractors only) This function resets all settings of MAIN MENU and INSTALLER SETTINGS to their factory settings. Following such a reset, your heating contractor will need to recommission the system! If the standard display is set: B Simultaneously press and hold menu until the following warning message appears:... -

Page 25: Adjusting The Main Menu

Adjusting the MAIN MENU | 25 Adjusting the MAIN MENU B Briefly push the menu key to open or close the The menu points are only shown if main menu. the system components are present B Turn the rotary selector to select the required and/or active, and if no remote menu point. - Page 26 26 | Adjusting the MAIN MENU Domestic hot water DHW and DHW circulation pump page 29 DHW programme page 30 All days ... Sunday P1, P2, ... P6 Reset factory settings DHW circ pump prog page 31 All days ... Sunday P1, P2, ...

- Page 27 Adjusting the MAIN MENU | 27 General settings page 34 Time and date Time Date Auto switch between GMT - BST Time adjustment Display format Date Display contrast Information at top of display Key lock Language Solar page 35 T2: Max. solar cylinder temperature Optimizing influence DHW CH circuit optimizing influence 1) Auto switch between GMT - BST always switch off (select No)

-

Page 28: Heating Program

28 | Adjusting the MAIN MENU B Return the heating program to its factory Heating program settings page 23. 6.2.2 Temperature for the operating modes Main menu: Heating (change temperature permanently) Set the flow temperature controller on the heating appliance to the Menu: Heating >... -

Page 29: Dhw Program

Adjusting the MAIN MENU | 29 With combi boiler: • DHW program – DHW On, if the heating system operates in Comfort mode or has operated in Main menu: Domestic hot water Comfort mode within the last hour. Set the DHW temperature controller –... -

Page 30: Time/Temperature Level Program For Dhw Via Cylinder

30 | Adjusting the MAIN MENU 6.3.2 Time/temperature level program for 6.3.3 Time program for DHW with combi boiler DHW via cylinder Menu: Domestic hot water > DHW programme Menu: Domestic hot water > DHW programme Use this menu if you want to use a time program Use this menu if you want to use a DHW program for DHW heating. -

Page 31: Time Program For Dhw Circulation Pump (Only With Dhw Cylinder)

Adjusting the MAIN MENU | 31 6.3.4 Time program for DHW circulation pump 6.3.5 Parameters for DHW (only with DHW cylinder) Menu: Domestic hot water > Parameter > Menu: Domestic hot water > DHW circ pump Cylinder temp at heating level Comf. prog This menu point is only active if Domestic hot Use this menu if you want to use a time program... -

Page 32: Thermal Disinfection Of Dhw

32 | Adjusting the MAIN MENU Menu: Domestic hot water > Parameter > DHW Operating mode: • circ pump cycles – Auto Thermal disinfection starts This menu point is only active if a DHW circulation automatically in accordance with the set pump is available. -

Page 33: Holiday Program

Adjusting the MAIN MENU | 33 Holiday program Main menu: Holiday Use this menu if you want to operate a special program for several days without changing your personal settings in the individual programs and parameters. With the holiday program, central heating and DHW heating operate according to the operating mode set in the holiday program (frost protection is ensured). -

Page 34: General Settings

34 | Adjusting the MAIN MENU 6.5.2 Display formats General settings Menu: General settings > Display format Main menu: General settings Use this menu if you want to customise the display formats to suit your personal 6.5.1 Time and Date preferences. -

Page 35: Solar Settings

Adjusting the MAIN MENU | 35 Optimizing influence DHW: Maximum • Solar settings reduction of set DHW temperature by effect of solar thermal system. Main menu: Solar Example: Use this menu if you want to limit the cylinder – Set DHW temperature = 60 °C temperature or optimise the set DHW –... -

Page 36: Viewing Information

36 | Viewing information Viewing information Menu: INFO INFO menu overview The table below provides: This menu allows you to view various items of An overview of the menu structure (column 1). system information. • The menu depth is identified by various Detailed instructions on navigating through the shades of grey. - Page 37 Viewing information | 37 Variable display Menu structure INFO (examples) Description Heating system – – Operating mode Auto – Comfort | Auto – Current operating mode or special mode for the Economy | Auto – Frost | heating system. Comfort | Economy | Frost | Holiday –...

- Page 38 Only starts 30 days after commissioning. Faults 40 Solar system List of current faults. More detailed information can 03 FW 120 be obtained by selecting with and confirming EA Boiler ... with 6 720 800 844 (2012/02)

-

Page 39: Menu Settings Installer Settings (Contractors Only)

Menu settings INSTALLER SETTINGS (contractors only) | 39 Menu settings INSTALLER SETTINGS (contractors only) An overview of the factory settings (column 2), • The INSTALLER SETTINGS menu is e.g. for the purposes of resetting individual intended only for contractors. menu point to their factory settings. B To open INSTALLER SETTINGS: An overview of the setting ranges of the •... -

Page 40: Heating Parameters

40 | Menu settings INSTALLER SETTINGS (contractors only) 8.1.2 INSTALLER SETTINGS: Heating parameters Menu structure Factory Personal Description Heating parameters setting Setting range setting from page Heating circuit type Radiators Foot point/End point | Underfloor heating | Radiators | Convectors Foot point 25 °C 10 °C ... -

Page 41: Installer Settings: Solar Sys Parameters

Menu settings INSTALLER SETTINGS (contractors only) | 41 8.1.4 INSTALLER SETTINGS: Solar sys parameters Menu structure Factory Personal Description Solar sys parameters setting Setting range setting from page 1. Standard system – – – SP: ON temperature 3 K ... 20 K difference (not lower than "SP: OFF temperature difference"... -

Page 42: Installer Settings: Cust Service

27.06.2012 (data – – from heating appliance) Controller part number and 7 777 777 777 – – model FW 120 (fixed factory setting) Controller date of manufacture 27.06.2012 (fixed – – factory setting) Controller software version JF11.12 (fixed – –... -

Page 43: Configuring The Heating System

Menu settings INSTALLER SETTINGS (contractors only) | 43 Configuring the heating system Parameters for heating Installer settings: System configuration Installer settings: Heating parameters For menu structure and setting ranges For menu structure and setting ranges page 40. page 39. Set the flow temperature controller For system examples, see the IPM on the heating appliance to the manual. - Page 44 44 | Menu settings INSTALLER SETTINGS (contractors only) 6 720 612 481-30.1R 6 720 612 481-27.1R Fig. 19 Default basic setting of heating curve for Fig. 21 Default setting for heating curve in base point/end point radiator heating system 6 720 612 481-29.1R 6 720 612 481-28.1R Fig.

- Page 45 Menu settings INSTALLER SETTINGS (contractors only) | 45 Default setting of parameters for heating curve Foot point/End point Underfloor heating Radiators Convectors Heating surface exponent (fixed – value), curvature of heating curve Minimum outside temperature – – 15 °C – 15 °C –...

- Page 46 – Lower temperature: Of the temperature 99 °C: Function switched off, i.e. the – sensors fitted in FW 120 and in FB 10, the heating system can switch on at any one with the lower captured temperature outside temperature.

-

Page 47: Configuring The Solar Thermal System

Menu: Heating parameters > Mixer running time B Set the Mixer running time to the runtime of B Position a precision instrument near FW 120. the fitted mixer servomotor. The precision instrument must not transfer any heat to the FW 120. -

Page 48: Parameters For Solar Thermal System

48 | Menu settings INSTALLER SETTINGS (contractors only) Menu: Solar sys parameters > 1. Standard Parameters for solar thermal system > SP: OFF temperature difference system B Same procedure as for the last menu point SP: ON temperature difference. Fill and vent the solar thermal system according to its Menu: Solar sys parameters >... -

Page 49: Parameters For Thermal

Menu settings INSTALLER SETTINGS (contractors only) | 49 Menu: Solar sys parameters > 1. Standard 8.5.3 Parameters for solar optimisation system > SP: Collector grp 1 pump mode Solar optimisation is performed automatically B Select the operating mode of the solar circuit according to the available solar output. - Page 50 50 | Menu settings INSTALLER SETTINGS (contractors only) Fig. 23 Map with the climate zones If the location where the system is installed cannot be found on the climate zone map Fig. 23): B Do not change the factory-set value for solar optimisation.

-

Page 51: Commissioning The Solar Thermal

Menu settings INSTALLER SETTINGS (contractors only) | 51 Menu: Solar sys parameters > Solar Viewing and entering the optimisation > Optimizing influence DHW customer service address Detailed description regarding Optimizing influence DHW page 35. Installer settings: Cust service address Menu: Solar sys parameters > Solar For menu structure and setting range page 42. -

Page 52: Screed Drying Function

52 | Menu settings INSTALLER SETTINGS (contractors only) Menu: Floor drying > Total floor drying time Screed drying function The total duration is automatically calculated. For this, the flow temperature increases by no more Installer settings: Floor drying than 10 K per day. If this temperature rise is For menu structure and setting range page 42. -

Page 53: Troubleshooting

Troubleshooting | 53 Troubleshooting BUS device faults are indicated. For the contractor: A heating appliance fault (e.g. EA fault) is B Remedy the fault in accordance displayed with the relevant advice. with the heating appliance B Contact your installer. documentation. Troubleshooting with display (contractors only) The current fault is displayed on the controller and on the remote control (on FB 10 without... - Page 54 Fault 02 See display text. Identify and replace faulty Internal fault controller/remote control. FW 120/FB100 can no longer control CH system Fault 03 Room temperature sensor built Identify and replace faulty Room temp sensor faulty into FW 120/FB 100/FB 10 has controller or remote control.

- Page 55 Fault 20 Invalid code in remote control In conjunction with FW 120 System configuration: invalid for heating circuit. only code 1 is possible in the remote control. 1) The display text is shown at the BUS subscriber (e.g. remote control) that has identified the fault. The other BUS subscribers will instead display the code that corresponds to the display text.

- Page 56 56 | Troubleshooting Information displayed ( items 1, 3 and 4 in Fig. 25) Text Code Cause Remedy (by contractor) Fault 21 See display text on remote control. System configuration: new BUS device Fault 22 IPM not recognised on remote Check IPM connection and System configuration: BUS device missing control with code 1.

- Page 57 Troubleshooting | 57 Information displayed ( items 1, 3 and 4 in Fig. 25) Text Code Cause Remedy (by contractor) Fault 50 Solar circuit pump (SP) Unscrew and remove slotted Solar pump jammed or air in system sticking due to physical screw on pump head and use a blockage.

-

Page 58: Troubleshooting Without Display

Installation location of FW 120 Select a better installation location for unfavourable, e.g. external wall, close to FW 120 and ask your heating contractor window, in a draught, ... to reposition it. Excessive room temperature Temporary influence of external heat on Arrange for your contractor to increase fluctuations. - Page 59 Troubleshooting | 59 If the fault persists: B Call an authorised contractor or the customer service department and inform them of the fault, quoting the appliance details (from type plate inside flap). Appliance details Type: ................Part number: ................Date of manufacture (FD...): ................

-

Page 60: Energy Saving Tips

60 | Energy saving tips 10 Energy saving tips With weather-compensated control, the flow Don't keep windows slightly open for • • temperature is controlled in accordance with ventilation. This leads to a constant extraction the set heating curve: The colder the outside of heat from the room without noticeably temperature, the higher the flow temperature. -

Page 61: Environmental Protection

Environmental protection | 61 11 Environmental protection Environmental protection is a fundamental corporate strategy of the Bosch Group. The quality of our products, their economy and environmental safety are all of equal importance to us and all environmental protection legislation and regulations are strictly observed. -

Page 62: Individual Time Program Settings

62 | Individual time program settings 12 Individual time program settings The factory settings and personal settings for the time programs are summarised below. 12.1 Heating program How to set the central heating program is described in chapter 6.2 on page 28. Factory settings Mo - Th 06:00... -

Page 63: Dhw Program

Individual time program settings | 63 12.2 DHW program How to set the DHW program is described in chapter 6.3 on page 29. °C °C °C °C °C °C Factory settings Mo - Th 05:00 23:00 – – – – –... -

Page 64: Dhw Circulation Program

64 | Individual time program settings 12.3 DHW circulation program How to set the DHW circulation program is described in chapter 6.3 on page 29. Factory settings Mo - Th 06:00 23:00 – – – – – – – – 06:00 23:00 –... -

Page 65: Index

Controller messages ........53 Installation ............11 Controls .............3 - Accessories ..........15 Cooler - FW 120 in the heating appliance ....11 - DHW ............29 - FW 120 wall mounting ....... 13 Customer service address ......42 - Outside temperature sensor ..... 14 Installation location - FW 120 ............ - Page 66 66 | Index Main menu Packaging ............61 - Heating ............28 Power reserve Menu - Mains power failure ........8 - Info .............36 Product details - Installer settings .........39 - Standard package ........8 Configuring solar thermal Programming system ........40 - Installer settings ........

- Page 67 Index | 67 Technical data ...........9 Thermal disinfection ......32 – Thermostatic valves .........60 Troubleshooting ..........53 Underfloor heating system ......60 Used appliances ..........61 Venting ............60 Wall mounting ..........13 6 720 800 844 (2012/02)

- Page 68 Australia Robert Bosch (Australia) Pty Ltd 1555 Centre Rd Clayton, VIC 3168 Phone 1300 30 70 37 Fax 1300 30 70 38 www.bosch.com.au/hotwater New Zealand Phone 0800 4 Bosch or 08 543 352 www.bosch.co.nz...