Table of Contents

Advertisement

Quick Links

Air-Conditioners

Кондиционеры

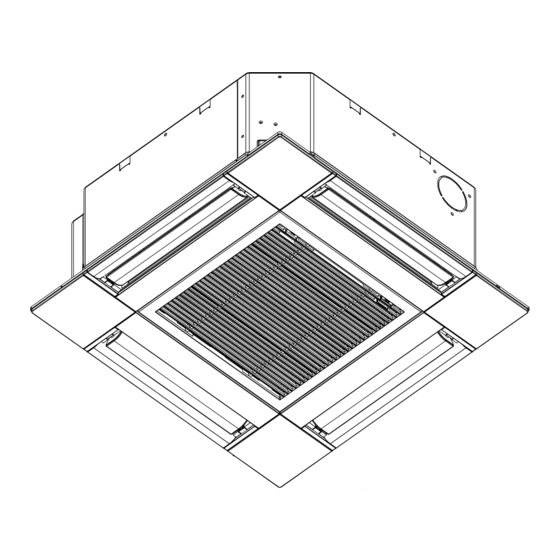

SLZ-KF25, KF35, KF50, KF60VA

INSTALLATION MANUAL

For safe and correct use, please read this manual and the outdoor unit installation manual thoroughly before install-

ing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Aus Sicherheitsgründen und zur richtigen Anwendung vor Installation der Klimaanlage die vorliegende Bedienungs-

anleitung und das Installationshandbuch gründlich durchlesen.

MANUEL D'INSTALLATION

Avant d'installer le climatiseur, lire attentivement ce manuel, ainsi que le manuel d'installation de l'appareil extérieur

pour une utilisation sûre et correct.

INSTALLATIEHANDLEIDING

Lees deze handleiding en de installatiehandleiding van het buitenapparaat zorgvuldig door voordat u met het instal-

leren van de airconditioner begint.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire

acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, prima di installare il condizionatore d'aria leggere attentamente il presente manuale ed

il manuale d'installazione dell'unità esterna.

EΓΧEIPIΔIO OΔHΓIΩN EΓKATAΣTAΣHΣ

Για σωστή και ασφαλή χρήση, διαβάστε προσεκτικά αυτό το εγχειρίδιο, καθώς και το εγχειρίδιο εγκατάστασης της

εξωτερικής μονάδας, πριν από την εγκατάσταση της μονάδας κλιματιστικού.

MANUAL DE INSTALAÇÃO

Para uma utilização segura e correcta, leia atentamente este manual e o manual de instalação da unidade exterior

antes de instalar o aparelho de ar condicionado.

INSTALLATIONSMANUAL

Læs af sikkerhedshensyn denne manual samt manualen til installation af udendørsenheden grundigt, før du

installerer klimaanlægget.

INSTALLATIONSMANUAL

Läs bruksanvisningen och utomhusenhetens installationshandbok noga innan luftkonditioneringen installeras så att

den används på ett säkert och korrekt sätt.

MONTAJ ELKİTABI

Emniyetli ve doğru kullanım için, klima cihazını monte etmeden önce bu kılavuzu ve dış ünite montaj kılavuzunu

tamamıyla okuyun.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для обеспечения безопасной и надлежащей эксплуатации внимательно прочтите данное руководство и

руководство по установке наружного прибора перед установкой кондиционера.

FOR INSTALLER

FÜR INSTALLATEURE

POUR L'INSTALLATEUR

VOOR DE INSTALLATEUR

PARA EL INSTALADOR

PER L'INSTALLATORE

ΓΙΑ ΑΥΤΟΝ ΠΟΥ ΚΑΝΕΙ ΤΗΝ ΕΓΚΑΤΑΣΤΑΣΗ

PARA O INSTALADOR

TIL INSTALLATØREN

FÖR INSTALLATÖREN

MONTÖR İÇİN

ДЛЯ УСТАНОВИТЕЛЯ

English

Deutsch

Français

Nederlands

Español

Italiano

Eλληνικά

Português

Dansk

Svenska

Türkçe

Русский

Advertisement

Table of Contents

Summary of Contents for Mitsubishi Electric Mr.SLIM SLZ-KF60VA

- Page 1 Air-Conditioners Кондиционеры SLZ-KF25, KF35, KF50, KF60VA INSTALLATION MANUAL FOR INSTALLER English For safe and correct use, please read this manual and the outdoor unit installation manual thoroughly before install- ing the air-conditioner unit. INSTALLATIONSHANDBUCH FÜR INSTALLATEURE Deutsch Aus Sicherheitsgründen und zur richtigen Anwendung vor Installation der Klimaanlage die vorliegende Bedienungs- anleitung und das Installationshandbuch gründlich durchlesen.

-

Page 2: Table Of Contents

Contents 1. Safety precautions ..................2 7. Electrical work ....................7 2. Selecting the installation location ..............2 8. Test run ......................13 3. Installation diagram ..................3 9. System control .................... 15 4. Installing the indoor unit ................. 3 10. -

Page 3: Installation Diagram

3. Installation diagram 3.1. Indoor unit (Fig. 3-1) (mm) A Ceiling B Grille C Obstacle D Min. 1000 mm E Min. 500 mm (Entire periphery) If setting the maintenance space for E, be sure to leave is a minimum of 700 mm. Warning: Mount the indoor unit on a ceiling strong enough to withstand the weight of the unit. 3.2. Outdoor unit Fig. 3-1 Refer to the outdoor unit installation manual. 4. Installing the indoor unit 4.1. Check the indoor unit accessories (Fig. 4-1) The indoor unit should be supplied with the following accessories. Accessory name Q’ty Installation template... - Page 4 4. Installing the indoor unit 4.3. Installation of duct (in case of fresh air intake) (mm) (Fig. 4-3) 120° Caution: Linkage of duct fan and air conditioner ln case that a duct fan is used, be sure to make it linked with the air conditioner when outside air is taken. Do not run the duct fan only. It can cause dew drop. Making a duct flange (prepared locally) • The shape of duct flange shown left is recommended. Installation of duct flange • Cut out the cutout hole. Do not knock it out. • Install a duct flange to the cutout hole of the indoor unit with three 4 × 10 tapping Duct flange connection screws which should be prepared locally. Installation of duct (should be prepared locally) • Prepare a duct of which inner diameter fits into the outer diameter of the duct flange. • In case that the environment above the ceiling is high temperature and high humidity, wrap the duct in a heat insulate to avoid causing dew drop on the wall. Remove the drain pan insulation. A Duct flange recommended shape F 3-Tapping screw hole (Thickness:0.8 or more) G ø73.4 cutout hole B 3-ø5 hole...

-

Page 5: Refrigerant Piping Work

5. Refrigerant piping work 5.1. Refrigerant pipe (Fig. 5-1) A Indoor unit Piping preparation B Outdoor unit ø6.35 • Refrigerant pipes of 3, 5, 7, 10 and 15 m are available as optional items. (1) Table below shows the specifications of pipes commercially available. Outside diameter Min. wall Insulation Insulation SLZ-KF25, KF35: ø9.52 Model Pipe SLZ-KF50: ø12.7 thickness thickness material inch SLZ-KF60: ø15.88 For liquid 6.35 0.8 mm 8 mm SLZ-KF25 Fig. 5-1 SLZ-KF35 Heat resist- For gas 9.52 0.8 mm... -

Page 6: Drainage Piping Work

5. Refrigerant piping work 5.4. Pipe connection (Fig. 5-8) Indoor unit 1) When using commercially available copper pipes: • Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening flare nut. • Use two wrenches to tighten piping connections. • Air-purge the refrigerant piping using your own refrigerant gas (don’t air-purge the refrigerant charged in the outdoor unit). • Use leak detector or soapy water to check for gas leaks after connections are completed. • Use refrigerant piping insulation provided to insulate indoor unit connections. Insulate carefully following shown below. 2) Heat insulation for refrigerant pipes: 1 Wrap the enclosed large-sized pipe cover around the gas pipe, making sure that A Refrigerant pipe and insulating material... -

Page 7: Electrical Work

6. Drainage piping work 1. Connect the drain socket (supplied with the unit) to the drain port. (Fig. 6-2) (mm) (Affix the tube using PVC adhesive then secure it with a band.) 2. Install a locally purchased drain pipe (PVC pipe, O.D. ø32). D E E (Affix the pipe using PVC adhesive then secure it with a band.) 30 30 3. Insulate the tube and pipe. (PVC pipe, O.D. ø32 and socket) 4. Check that drain flows smoothly. 5. Insulate the drain port with insulating material, then secure the material with a band. (Both insulating material and band are supplied with the unit.) A Main unit G Drain pipe (O.D. ø32 PVC TUBE) B Insulating material H Insulating material (purchased locally) C Band (large) I Transparent PVC pipe D Drain port (transparent) J O.D. ø32 PVC TUBE (Slope 1/100 or more) Fig. 6-2 E Insertion margin K Band (middle) F Matching L Drain socket... - Page 8 7. Electrical work Fig. 7-4 Caution: • Before installing the grille, make sure that the junction wire is connected. • If the grille has signal receiver or i-See sensor, the pack of grille includes junction wire. Signal receiver: CN90 Secure with a band 4 (small) 3D i-See sensor: CN5Y at the location shown in the 3D i-See sensor motor: CN4Z diagram CN5Y Secure with a band 4 (small) at the CN4Z location shown in the diagram...

- Page 9 7. Electrical work 7.3. Remote controller 7.3.1. Wired remote controller 1) Installing procedures MODEL SELECT Refer to the installation manual that comes with each remote controller for details. 2) Function selection of remote controller If two remote controllers are connected, set one to “Main” and the other to “Sub”. For ON/OFF TEMP setting procedures, refer to “Function selection of remote controller” in the operation manual for the indoor unit. 7.3.2. For wireless remote controller AUTO STOP 1) Installation area • Area in which the remote controller is not exposed to direct sunshine.

- Page 10 7. Electrical work 7.4. Function settings Service menu Function setting 7.4.1. By wired remote controller Test run Ref. address 1 (Fig. 7-13) Input maintenance info. Unit No. Grp./1/2/3/4/All Function setting • Select “Service” from the Main menu, and press the [SELECT] button. Check • Select “Function setting” with the [F1] or [F2] button, and press the [SELECT] Self check button. Main menu: Monitor: Cursor Cursor Address 2 (Fig. 7-14) • Set the indoor unit refrigerant addresses and unit numbers with the [F1] through [F4] buttons, and then press the [SELECT] button to confirm the cur- rent setting.

- Page 11 7. Electrical work Function table Select unit number 00 Initial set- Mode Settings Mode no. Setting no. setting ting Power failure automatic recovery Not available Available Ο Indoor temperature detecting Indoor unit operating average Ο Set by indoor unit’s remote controller Remote controller’s internal sensor LOSSNAY connectivity Not Supported Ο Supported (indoor unit is not equipped with outdoor-air intake) Supported (indoor unit is equipped with outdoor-air intake) Power voltage 240 V 220 V, 230 V Ο Select unit numbers 01 to 03 or all units (AL [wired remote controller]/07 [wireless remote controller]) Initial set- Mode Settings Mode no.

- Page 12 7. Electrical work The current vane setting will appear. Manual vane angle Select the desired outlets from 1 through 4 with the [F1] or [F2] button. • Outlet: "1", "2", "3", "4", and "1, 2, 3, 4, (all outlets)" Press the [F3] or [F4] button to go through the option in the order of "No setting (re- Select: Outlet Angle set)", "Step 1", "Step 2", "Step 3", "Step 4", "Step 5", and "Draft reduction*". Select the desired setting. ■ Vane setting No setting Step 1 Step 2 Step 3 Step 4 Step 5 Manual vane angle Draft All outlets Setting reduction* * Draft reduction The airflow direction for this setting is more horizontal than the airflow direction for the “Step 1” setting in order to reduce a drafty feeling. The draft reduction can be set for only 1 vane.

-

Page 13: Test Run

8. Test run 8.1. Before test run ► After completing installation and the wiring and piping of the indoor and ► Do not carry out this test on the control wiring (low voltage circuit) termi- outdoor units, check for refrigerant leakage, looseness in the power sup- nals. ply or control wiring, wrong polarity, and no disconnection of one phase Warning: in the supply. Do not use the air conditioner if the insulation resistance is less than 1.0 MΩ. ► Use a 500-volt megohmmeter to check that the resistance between the power supply terminals and ground is at least 1.0 MΩ. 8.2. Test run 8.2.1. Using wired remote controller ■ Make sure to read operation manual before test run. (Especially items to secure safety) Step 1 Turn on the power. ● Remote controller: The system will go into startup mode, and the remote controller power lamp (green) and “PLEASE WAIT” will blink. While the lamp and message are blinking, the remote controller cannot be operated. Wait until “PLEASE WAIT” is not displayed before operating the remote controller. After the power is turned on, “PLEASE WAIT” will be displayed for approximately 2 minutes. ● Indoor controller board: LED 1 will be lit up, LED 2 will be lit up (if the address is 0) or off (if the address is not 0), and LED 3 will blink. ● Outdoor controller board: LED 1 (green) and LED 2 (red) will be lit up. (After the startup mode of the system finishes, LED 2 will be turned off.) If the outdoor controller board uses a digital display, [- ] and [ -] will be displayed alternately every second. - Page 14 8. Test run Step 5 Stop the test run. 1 Press the [ON/OFF] button to stop the test run. (The Test run menu will appear.) Note: If an error is displayed on the remote controller, see the table below. [Output pattern A] Errors detected by indoor unit Wired remote Wireless remote controller controller Beeper sounds/OPERATION Symptom Remark INDICATOR lamp blinks (Num- Check code ber of times) Intake sensor error Pipe (TH2) sensor error Pipe (TH5) sensor error E6, E7 Indoor/outdoor unit communication error Drain sensor error / Float switch connector open Drain pump error Forced compressor error Freezing/Overheating protection operation Communication error between indoor and outdoor units Pipe temperature error Remote controller signal receiving error —...

-

Page 15: System Control

8. Test run 8.3. Self-check ■ Refer to the installation manual that comes with each remote controller for details. 8.4. Check of drainage (Fig. 8-5) A Water supply pump B Water (about 1000 cc) • Ensure that the water is being properly drained out and that no water is leaking C Drain plug from joints. D Pour water through outlet When electric work is completed. • Be careful not to spray water into • Pour water during cooling operation and check. the drain pump mechanism. When electric work is not completed. • Pour water during emergency operation and check. * Drain pump and fan are activated simultaneously when single phase 230 V is turned on to S1 and S2 on terminal block after the connector (SWE) on controller board in the electrical component box is set to ON. - Page 16 10. Installing the grille 10.2.2. Removing the corner panel (Fig. 10-4) • Loosen the screw from the corner of the corner panel. Slide the corner panel as indicated by the arrow 1 to remove the corner panel. A Grille B Corner panel C Screw Fig. 10-4 10.3. Installing the grille <Hook is in the raised position> <Grille hook> • Please pay attention because there is a restriction in the attachment position of the grille. 10.3.1. Temporarily installing the grille • Align the screw holes in the corners of the grille with the screw mounting holes in the corners of the main unit, latch the two hooks on the grille onto the drain pan projections on the main unit, and temporarily hang the grille. (Fig. 10-5) Caution: When installing the i-See sensor and signal receiver, place the junction wires in the connector box before temporarily hanging the grille. Main unit hook Refer to 7.2.1. on page 8 to route the junction wires.

- Page 17 10. Installing the grille 10.3.4. Wiring the i-See sensor corner panel and signal receiver • Install the i-See sensor and signal receiver at the corners of the panel at the loca- tions stamped with “○” or “□”. (The positions may be reversed.) • Route the i-See sensor and signal receiver wires through the square holes at the corners of the panel and install them. • Connect the junction wire connector and the wire connectors of the i-See sensor and signal receiver in the connector box. • Close the connector box cover. • Secure the i-See sensor and signal receiver wires to the panel with the fastener as shown in the diagram so that there is no slack in the wires, and then cut off the excess end of the fastener. (Fig.10-12) • Place the i-See sensor and signal receiver wires to the inside of the flange on the Fig. 10-11 panel. • If the position of the i-See sensor was changed from the “○” position (E) to the “□” position (F), change the function settings. (Refer to page 11.) Caution: • Route the i-See sensor and signal receiver wires as shown in Fig. 10-13. • Place the excess portions of the i-See sensor and signal receiver junction wires in the electric component box in the wire clip as shown in the diagram, and secure the wires together with the fastener. (Fig. 10-14) Make sure that the band securing the i-See sensor and signal receiver junction wires is positioned inside the connector box. (Fig. 10-15) • If the vane motor connectors and signal receiver connector are connected incorrectly, the vanes will not move or communication with the remote con- troller will not be possible.

-

Page 18: Easy Maintenance Function

10. Installing the grille 10.5. Installing the intake grille (Fig. 10-17) • Perform the procedure that is described in “10.2. Preparing to attach the grille” in reverse order to install the intake grille and the corner panel. A Refrigerant piping of the main unit B Drain piping of the main unit C Corner panel D Position of the levers on the intake grille when sent from the factory. * Although the clips can be installed in any of four positions. E Receiver 10.6. Check Signal receiver • Make sure that there is no gap between the unit and the grille, or between the grille and the surface of the ceiling. If there is any gap between the unit and the grille, or between the grille and the surface of the ceiling, it may cause dew to collect. • Make sure that the wires have been securely connected. • Check that all four vanes move. If two or four vanes do not move, refer to 10.3 and check the connections. - Page 19 Не забудьте указать контактный адрес/номер телефона в данном руководстве, прежде чем передать его клиенту. HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN Authorized representative in EU: MITSUBISHI ELECTRIC EUROPE B.V HARMAN HOUSE, 1 GEORGE STREET, UXBRIDGE, MIDDLESEX UB8 1QQ, UK Название...