ABB Power2 340-H44 Manuals

Manuals and User Guides for ABB Power2 340-H44. We have 11 ABB Power2 340-H44 manuals available for free PDF download: Operation Manual

ABB Power2 340-H44 Operation Manual (124 pages)

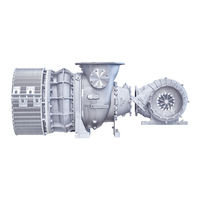

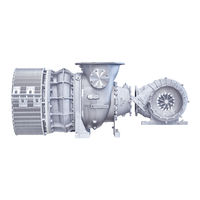

Low-pressure stage

Brand: ABB

|

Category: Industrial Equipment

|

Size: 13.03 MB

Table of Contents

-

-

Fig. 210

-

Fig. 311

-

Safety16

-

Introduction16

-

Intended Use18

-

Oil Supply38

-

Table 1343

-

Table 1443

-

Speeds44

-

Service Work49

-

Table 1653

-

Table 1754

-

Introduction68

Advertisement

ABB Power2 340-H44 Operation Manual (124 pages)

Brand: ABB

|

Category: Industrial Equipment

|

Size: 13.03 MB

Table of Contents

-

-

Fig. 210

-

Fig. 311

-

Safety16

-

Introduction16

-

Intended Use18

-

Oil Supply38

-

Table 1343

-

Table 1443

-

Speeds44

-

Service Work49

-

Table 1653

-

Table 1754

-

Introduction68

ABB Power2 340-H44 Operation Manual (116 pages)

Brand: ABB

|

Category: Industrial Equipment

|

Size: 13.29 MB

Table of Contents

-

-

Safety16

-

Introduction16

-

Intended Use18

-

Table 1242

-

Oil Supply43

-

Table 1448

-

Table 1548

-

Speeds49

-

Service Work54

-

Table 1758

-

Table 1859

-

Introduction71

-

Spare Parts99

-

Table 55101

-

Table 56102

-

Table 57103

-

Table 58104

-

Table 59105

-

Table 60106

-

Table 61107

-

Table 62108

-

Table 63109

-

Table 64110

-

Table 65111

-

Tools112

Advertisement

ABB Power2 340-H44 Operation Manual (116 pages)

Brand: ABB

|

Category: Industrial Equipment

|

Size: 13.29 MB

Table of Contents

-

-

Safety16

-

Introduction16

-

Intended Use18

-

Table 1242

-

Oil Supply43

-

Table 1448

-

Table 1548

-

Speeds49

-

Service Work54

-

Table 1758

-

Table 1859

-

Introduction71

-

Spare Parts99

-

Table 55101

-

Table 56102

-

Table 57103

-

Table 58104

-

Table 59105

-

Table 60106

-

Table 61107

-

Table 62108

-

Table 63109

-

Table 64110

-

Table 65111

-

Tools112

ABB Power2 340-H44 Operation Manual (116 pages)

Brand: ABB

|

Category: Industrial Equipment

|

Size: 13.28 MB

Table of Contents

-

-

Safety16

-

Introduction16

-

Intended Use18

-

Table 1242

-

Oil Supply43

-

Table 1448

-

Table 1548

-

Speeds49

-

Service Work54

-

Table 1758

-

Table 1859

-

Introduction71

-

Spare Parts99

-

Table 55101

-

Table 56102

-

Table 57103

-

Table 58104

-

Table 59105

-

Table 60106

-

Table 61107

-

Table 62108

-

Table 63109

-

Table 64110

-

Table 65111

-

Tools112

ABB Power2 340-H44 Operation Manual (116 pages)

Brand: ABB

|

Category: Industrial Equipment

|

Size: 13.29 MB

Table of Contents

-

-

Safety16

-

Introduction16

-

Intended Use18

-

Table 1242

-

Oil Supply43

-

Table 1448

-

Table 1548

-

Speeds49

-

Service Work54

-

Table 1758

-

Table 1859

-

Introduction71

-

Spare Parts99

-

Table 55101

-

Table 56102

-

Table 57103

-

Table 58104

-

Table 59105

-

Table 60106

-

Table 61107

-

Table 62108

-

Table 63109

-

Table 64110

-

Table 65111

-

Tools112

ABB Power2 340-H44 Operation Manual (116 pages)

Brand: ABB

|

Category: Industrial Equipment

|

Size: 13.29 MB

Table of Contents

-

-

Safety16

-

Introduction16

-

Intended Use18

-

Table 1242

-

Oil Supply43

-

Table 1448

-

Table 1548

-

Speeds49

-

Service Work54

-

Table 1758

-

Table 1859

-

Introduction71

-

Spare Parts99

-

Table 55101

-

Table 56102

-

Table 57103

-

Table 58104

-

Table 59105

-

Table 60106

-

Table 61107

-

Table 62108

-

Table 63109

-

Table 64110

-

Table 65111

-

Tools112

ABB Power2 340-H44 Operation Manual (116 pages)

Brand: ABB

|

Category: Industrial Equipment

|

Size: 13.28 MB

Table of Contents

-

-

Safety16

-

Introduction16

-

Intended Use18

-

Table 1242

-

Oil Supply43

-

Table 1448

-

Table 1548

-

Speeds49

-

Service Work54

-

Table 1758

-

Table 1859

-

Introduction71

-

Spare Parts99

-

Table 55101

-

Table 56102

-

Table 57103

-

Table 58104

-

Table 59105

-

Table 60106

-

Table 61107

-

Table 62108

-

Table 63109

-

Table 64110

-

Table 65111

-

Tools112

ABB Power2 340-H44 Operation Manual (116 pages)

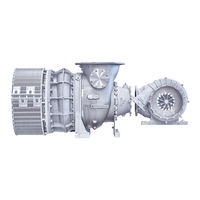

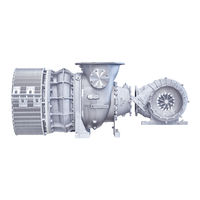

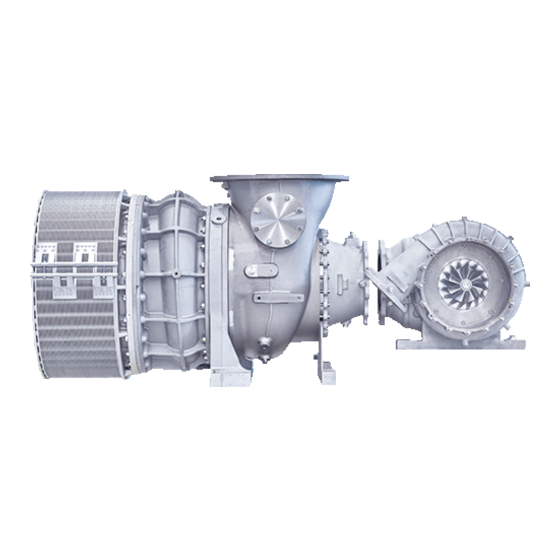

High-pressure stage

Brand: ABB

|

Category: Industrial Equipment

|

Size: 13.29 MB

Table of Contents

-

-

Safety16

-

Introduction16

-

Intended Use18

-

Table 1242

-

Oil Supply43

-

Table 1448

-

Table 1548

-

Speeds49

-

Service Work54

-

Table 1758

-

Table 1859

-

Introduction71

-

Spare Parts99

-

Table 55101

-

Table 56102

-

Table 57103

-

Table 58104

-

Table 59105

-

Table 60106

-

Table 61107

-

Table 62108

-

Table 63109

-

Table 64110

-

Table 65111

-

Tools112

ABB Power2 340-H44 Operation Manual (116 pages)

High-pressure stage

Brand: ABB

|

Category: Industrial Equipment

|

Size: 13.29 MB

Table of Contents

-

-

Safety16

-

Introduction16

-

Intended Use18

-

Table 1242

-

Oil Supply43

-

Table 1448

-

Table 1548

-

Speeds49

-

Service Work54

-

Table 1758

-

Table 1859

-

Introduction71

-

Spare Parts99

-

Table 55101

-

Table 56102

-

Table 57103

-

Table 58104

-

Table 59105

-

Table 60106

-

Table 61107

-

Table 62108

-

Table 63109

-

Table 64110

-

Table 65111

-

Tools112

ABB Power2 340-H44 Operation Manual (116 pages)

High-pressure stage

Brand: ABB

|

Category: Industrial Equipment

|

Size: 13.29 MB

Table of Contents

-

-

Safety16

-

Introduction16

-

Intended Use18

-

Table 1242

-

Oil Supply43

-

Table 1448

-

Table 1548

-

Speeds49

-

Service Work54

-

Table 1758

-

Table 1859

-

Introduction71

-

Spare Parts99

-

Table 55101

-

Table 56102

-

Table 57103

-

Table 58104

-

Table 59105

-

Table 60106

-

Table 61107

-

Table 62108

-

Table 63109

-

Table 64110

-

Table 65111

-

Tools112

Advertisement