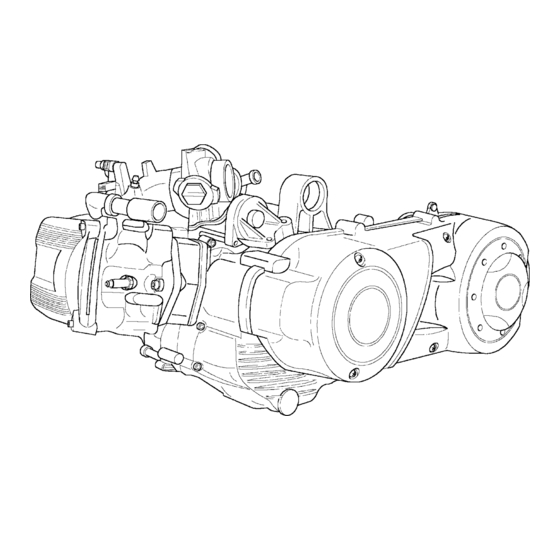

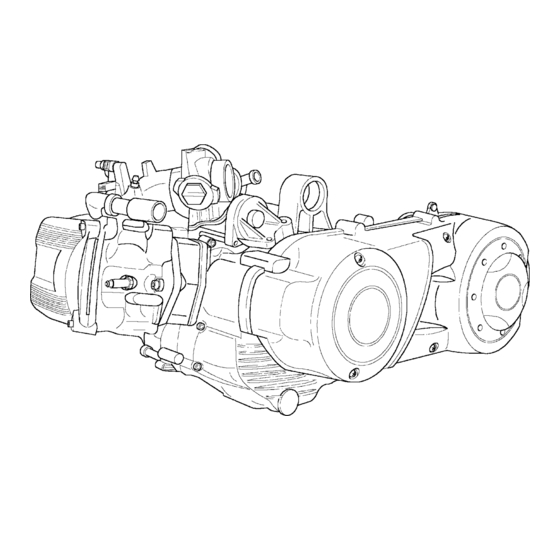

PIAGGIO 500 cc Manuals

Manuals and User Guides for PIAGGIO 500 cc. We have 1 PIAGGIO 500 cc manual available for free PDF download: Service Manual

Advertisement

Advertisement