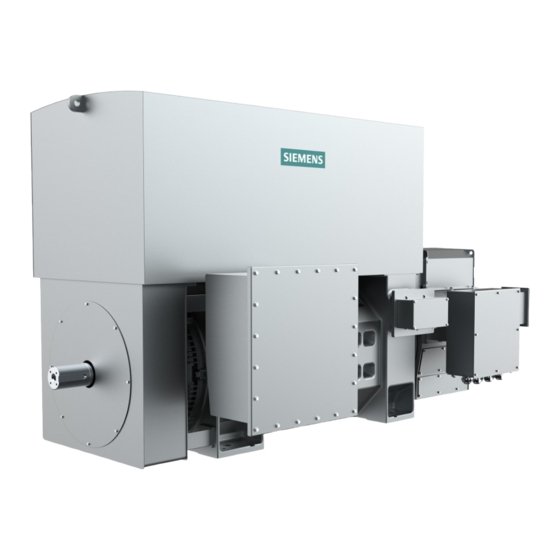

Siemens SIMOTICS HV M Manuals

Manuals and User Guides for Siemens SIMOTICS HV M. We have 1 Siemens SIMOTICS HV M manual available for free PDF download: Operating Instructions Manual

Advertisement

Advertisement