Siemens SIMOTICS S-1FG1 Operating Instructions Manual

Servo geared motors

Hide thumbs

Also See for SIMOTICS S-1FG1:

- Service instructions manual (54 pages) ,

- Operating instructions manual (170 pages)

Summary of Contents for Siemens SIMOTICS S-1FG1

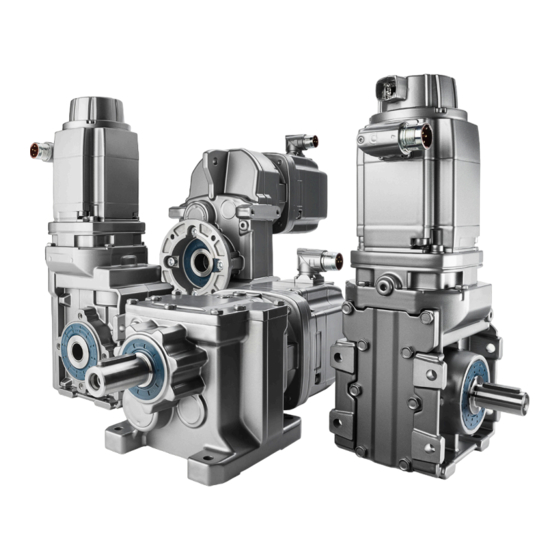

- Page 1 Edition 12/2022 OPERATING INSTRUCTIONS SIMOTICS SIMOTICS S-1FG1 servo geared motors Helical geared motors, parallel shaft geared motors, bevel geared motors and helical worm geared motors www.siemens.com...

- Page 3 Introduction Fundamental safety instructions for the SIMOTICS documentation SIMOTICS Description Drive technology Preparing for use SIMOTICS S-1FG1 servo geared Features and mounting motor positions of the servo geared motors Operating Instructions Mounting and assembly Connecting Commissioning Operation Faults Service and maintenance...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Table Of Contents

Websites of third-party companies..................11 SIMOTICS documentation ....................12 Service and support ......................13 1.4.1 Siemens Industry Online Support on the Web..............13 1.4.2 Siemens Industry Online Support on the road..............13 1.4.3 Feedback on the technical documentation ................. 14 1.4.4... - Page 6 Torque arms with shaft-mounted gearboxes ..............118 6.10 Mounting the oil expansion unit..................121 6.11 Vibration response......................123 Connecting ............................125 Safety instructions ......................125 Permissible line system types ................... 127 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 7 Service life of the lubricants ..................... 178 11.2.3.8 Recommended lubricants....................179 11.2.3.9 Oil quantities ........................181 11.2.4 Checking the gearbox for leaks..................181 11.2.5 Cleaning the servo geared motor ..................182 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 8 12.2.1 Preparing for dismantling....................188 12.2.2 Dismantling the motor ..................... 188 12.3 Disposal........................... 189 Appendix............................191 Certificate for the "PS Premium" painting system from ECOLAB.......... 191 ECOLAB cleaning recommendation .................. 194 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 9: Introduction

Introduction About SIMOTICS Description SIMOTICS is the Siemens family of electric motors addressing the complete motor spectrum in Digital Industry. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 10: About This Manual

Unless explicitly contractually agreed, Siemens assumes no liability for such suitability. Suitability for a particular application in specific individual cases must be assessed by the user, taking into account all technical, legal, and other requirements on a case-by-case basis. -

Page 11: Text Attributes

This document contains recommendations relating to third-party products. Siemens accepts the fundamental suitability of these third-party products. You can use equivalent products from other manufacturers. Siemens does not accept any warranty for the properties of third-party products. 1.2.2 Text attributes Description The chapter describes how text features are marked in this document. -

Page 12: Target Group

This documentation describes the functionality of the standard scope. This scope may differ from the scope of the functionality of the system that is actually supplied. Please refer to the ordering documentation only for the functionality of the supplied drive system. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 13: Websites Of Third-Party Companies

This document may contain hyperlinks to third-party websites. Siemens is not responsible for and shall not be liable for these websites and their content. Siemens has no control over the information which appears on these websites and is not responsible for the content and information provided there. -

Page 14: Simotics Documentation

Online help Instructions for configuring, program‐ Configuration engineers, program‐ ming, and commissioning mers, commissioning engineers Not all documentation classes are available for every SIMOTICS / SIMOGEAR / SINAMICS product. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 15: Service And Support

Service and support 1.4.1 Siemens Industry Online Support on the Web Description The following is available via Siemens Industry Online Support (https:// support.industry.siemens.com/cs/ww/en/), among others: • Product support • Global forum for information and best practice sharing between users and specialists •... -

Page 16: Feedback On The Technical Documentation

1.4.3 Feedback on the technical documentation Description We welcome your questions, suggestions, and corrections for this technical documentation. Please use the "Provide feedback" link at the end of the entries in Siemens Industry Online Support. Figure 1-2 Requests and feedback SIMOTICS S-1FG1 servo geared motor... -

Page 17: Mysupport Documentation

• "Industry Online Support" mobile app The Support Request is the most important input channel for questions relating to products from Siemens Industry. This will assign your request a unique ticket number for tracking purposes. The Support Request offers you: •... -

Page 18: Training

Description SITRAIN – Digital Industry Academy offers a comprehensive range of training courses on Siemens industrial products – directly from the manufacturer, for all industries and use cases, for all knowledge levels from beginner to expert. More information can be found on the Internet via the following address (https:// www.siemens.com/sitrain). -

Page 19: Important Product Information

If you wish to use special versions and design variants whose specifications vary from the servo geared motors described in this document, then contact your local Siemens office. If you have any questions regarding the intended usage, please contact your local Siemens office. -

Page 20: Predictable Incorrect Use

Predictable incorrect use WARNING Injuries due to incorrect use If you use the motor other than how SIEMENS intended, then death or severe injury can occur. You destroy or damage the motor. Misuse includes, for example • Not complying with the operating instructions or the Configuration Manual •... -

Page 21: Fundamental Safety Instructions For The Simotics Documentation

Contact with hazardous voltage can result in severe injury or death. • Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV- (Protective Extra Low Voltage) output voltages for all connections and terminals of the electronics modules. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 22 • Tighten all power connections to the prescribed torque. • Check all power connections at regular intervals, particularly after equipment has been transported. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 23 • Therefore, if you move closer than 20 cm to the components, be sure to switch off radio devices, cellphones or WLAN devices. • Use the "SIEMENS Industry Online Support app" only on equipment that has already been switched off. WARNING Unrecognized dangers due to missing or illegible warning labels Dangers might not be recognized if warning labels are missing or illegible.

- Page 24 • When transporting or storing permanent-magnet motors always use the original packing materials with the warning labels attached. • Clearly mark the storage locations with the appropriate warning labels. • IATA regulations must be observed when transported by air. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 25 • Mount drive components so that they are not accessible during operation. Measures when maintenance is required: • Allow drive components to cool off before starting any work. • Use appropriate personnel protection equipment, e.g. gloves. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 26: Equipment Damage Due To Electric Fields Or Electrostatic Discharge

Siemens’ products and solutions undergo continuous development to make them more secure. Siemens strongly recommends that product updates are applied as soon as they are available and that the latest product versions are used. Use of product versions that are no longer supported, and failure to apply the latest updates may increase customer’s exposure... -

Page 27: Residual Risks Of Power Drive Systems

– Component failure – Software errors – Operation and/or environmental conditions outside the specification – External influences/damage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 28 For more information about the residual risks of the drive system components, see the relevant sections in the technical user documentation. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 29: Description

Description Overview The SIMOTICS S-1FG1 servo geared motor forms a single system comprising a mechanical gearbox and a compact, permanent-magnet synchronous motor. The available options, gearbox variants and encoders, together with the expanded product range, mean that the 1FG1 servo geared motors can be optimally adapted to any application. -

Page 30: Technical Features And Ambient Conditions

SIMOTICS motors do not fall within the scope covered by the Machinery Directive. However, the use of the products in a typical machine application has been fully assessed for compliance with the main regulations in this directive concerning health and safety. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 31 UL or cUL mark on the rating plate! Quality systems Siemens employs a quality management system that meets the requirements of ISO 9001 and ISO 14001. Certificates for SIMOTICS motors can be downloaded from the Internet at the following link: Certificates for SIMOTICS motors (https://support.industry.siemens.com/cs/ww/de/ps/13347/...

-

Page 32: General Technical Features Of The 1Fg1 Servo Geared Motor

Resolver, multipole (number of pole pairs corresponds to number of pole pairs of the motor) • AM25EN22 absolute encoder, 25-bit singleturn, 4096 rev‐ olutions, with EnDat2.2 interface for SH 48 to SH 100 • 2-pole resolver SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 33: Ambient Conditions

DIN IEC 60721‑3‑3: 1995-09. The environmental effects and their limit values are defined in various classes in this standard. You can assign the SIMOTICS S-1FG1 servo geared motors to climate class 3K4 with the exception of the environmental factor "condensation". Condensation is not permissible. -

Page 34: Address Of Ce-Authorized Manufacturer

The CE Declaration of Conformity is held on file available to the competent authorities at the following address: Siemens AG Digital Industries Motion Control Industriestraße 1 DE-97616 Bad Neustadt a. d. Saale Germany SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 35: Derating Factors

8000 0.444 As the DC-link voltage is reduced, the converter output voltage also decreases. Operation in a vacuum is not permissible because of the low dielectric strength and poor heat dissipation. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 36: Structure Of The Article No

The article number comprises a combination of digits and letters. You can find possible combinations in the Catalog D41 (https://support.industry.siemens.com/cs/ww/en/ view/109747093). Note Note that not every theoretical combination is possible in practice. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 37 Motor shaft height 48 Motor shaft height 63 Motor shaft height 80 Motor shaft height 100 Motor length Motor length 0 Motor length 1 Motor length 2 Motor length 3 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 38 Flange-mounted design - for flange-mounted design see Chapter "Options" in Catalog D41 Housing flange-mounted design Gear ratio Options Coded Order code required - see Chapter "Options" in Catalog D41 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 39: Rating Plate Data Of The Servo Geared Motor

Resolver p=4 N04 BRAKE 24VDC_38,0W_2610005 M =19,0Nm Kundenangabe RN 000 Siemens AG, DE-97616 Bad Neustadt Made in Germany Product name, three-phase motor, Article 14 Mounting position and output side of the No. (without order codes) geared motor Serial number (ID No., production number) -

Page 40: Type Designations Of The Gearbox

Hollow shaft Fixing (-) Foot-mounted design Foot/flange-mounted design Flange-mounted design (A type) Housing flange (C type) Torque arm Connection (-) Feather key Shrink disk Hollow shaft with splines SIMOLOC assembly system SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 41 Article Helical gearbox Two stage Helical gearbox Three stage Parallel shaft gearbox Two stage Parallel shaft gearbox Three stage Bevel gearbox Two stage/three stage Helical worm gearbox Two stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 42: Mounting And Options

To ensure adequate heat dissipation of the 1FG1, maintain a minimum clearance of 100 mm from adjacent components on three lateral surfaces. Contact Technical Support if the gearbox housing temperature exceeds a value of +80 °C. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 43: Thermal Motor Protection

This can result in unintended movement of the machine or system, which can result in severe injury or death. • Strictly observe the permissible number of operating cycles. • Operate the servo geared motor only in conjunction with an intact brake. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 44: Direct Connection Of The Holding Brake To Sinamics Devices

3.6.4.3 Connection of the holding brake to an external power supply via contactor You can control the holding brake via an external power supply. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 45 Integrate a protective circuit in the feeder cable. In this way, you avoid switching overvoltages and possible influence of the system environment. See the following diagram Figure 3-2 Suggested circuit for the external power supply with protective circuit SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 46: Permanent Magnet Brake

(electromagnetically opening system). It also works according to the closed-circuit principle. For the technical data, see Chapter "Configuring guide" in Catalog D41. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 47 • Immediately shut down the machine or system if the manual release lever cannot be placed in the vertical position. • Only restart the system when it is absolutely guaranteed that the manual brake release functions perfectly. • In normal operation, remove the manual release lever. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 48 Removing the manual release lever of the spring-loaded brake 1. Place the manual release lever in the vertical position. 2. Remove the manual release lever. You have secured the spring-loaded brake against unintended actuation. ❒ SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 49 You can check the width of air gap s of the spring-loaded brake through the opening provided. The width of the air gap indicates the state of wear of the armature disk. The wider the air gap, the higher the armature disk wear. Figure 3-5 Top view SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 50 The wear limit of the brake has been reached when the air gap reaches the value s You must replace the brake to ensure continued functional safety. You cannot adjust the brake. Consult with your SIEMENS contact person. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 51: Increased Chemical Resistance

3.6.5 Increased chemical resistance SIMOTICS S-1FG1 servo geared motors are available in a version with increased chemical resistance. The corresponding order code is N16. The paint of these servo geared motors is resistant to numerous common cleaning agents and disinfectants. - Page 52 Description 3.6 Mounting and options SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 53: Preparing For Use

• When receiving the delivery, immediately check whether the scope of delivery matches the accompanying documents. Note Siemens will not accept any claims for missing or incorrect items submitted at a later date. • Register a complaint about – any apparent transport damage with the transport company immediately –... - Page 54 • Check the servo geared motor for completeness and damage. • Report any missing parts or damage immediately. • Remove and dispose of the packaging material and transport fixtures in accordance with local regulations. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 55: Transportation And Storage

1. For transport, screw the lifting eyes (lifting eyebolts) into the appropriate locations depending on the specific orientation of the servo geared motor. Use laminated washers. 2. Hook the crossbar into the lifting eyes (lifting eyebolts). SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 56: Storing The Servo Geared Motor

Store the 1FG1 servo geared motor in a dry, dust-free and vibration-free indoor area. Maintain the following values: • v < 0.2 mm/s • Max. temperatures: -15 °C to 70 °C • Mean relative humidity < 75 % SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 57 • Check the state of the desiccant and replace when necessary. • Record the preservation work so that all preservation coating can be removed from the servo geared motor prior to commissioning. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 58 Preparing for use 4.2 Transportation and storage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 59: Features And Mounting Positions Of The Servo Geared Motors

Gearbox shaft bearings All shafts are mounted in rolling bearings. The rolling bearings are lubricated using splash lubrication or oil-spray lubrication. Bearings that are not supplied with lubricant are sealed and grease-lubricated. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 60 External noise Noise that is not generated by the servo geared motor, but emitted from it, is not take into consideration. Noise emitted by the driven load is not taken into consideration. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 61: Mounting Positions

Identifying marking for oil drain, opposite side Table 5-3 Symbols - Supplements Symbol Meaning A, B Output side A, output side B ② 2-stage gearbox ③ 3-stage gearbox Position of the connection plug … SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 62: Helical Geared Motor (2 Stage And 3 Stage: Z And D)

Helical geared motor (2 stage and 3 stage: Z and D) Figure 5-1 Mounting positions for servo helical geared motors Z and D, foot-mounted design, frame sizes 19 - 29, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 63 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-2 Mounting positions for servo helical geared motors Z and D, foot-mounted design, frame sizes 39 - 129, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 64 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-3 Mounting positions for servo helical geared motors ZB and DB, foot-mounted and flange- mounted designs, frame sizes 29, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 65 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-4 Mounting positions for servo helical geared motors ZB and DB, foot-mounted and flange-mounted designs, frame sizes 39 - 89, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 66 5.2 Mounting positions Figure 5-5 Mounting positions for servo helical geared motors DF and ZF (flange-mounted design) or DZ and ZZ (housing flange design), frame sizes 19 - 29, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 67 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-6 Mounting positions for servo helical geared motors DF and ZF (flange-mounted design) or DZ and ZZ (housing flange design), frame size 39, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 68 5.2 Mounting positions Figure 5-7 Mounting positions for servo helical geared motors DF and ZF (flange-mounted design) or DZ and ZZ (housing flange design), frame sizes 49 - 129, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 69: Parallel Shaft Geared Motor (2 Stage And 3 Stage: Fz And Fd)

Parallel shaft geared motor (2 stage and 3 stage: FZ and FD) Figure 5-8 Mounting positions for servo parallel shaft geared motors FZ and FD, foot-mounted design, frame size 29, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 70 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-9 Mounting positions for servo parallel shaft geared motors FZ and FD, foot-mounted design, frame size 39 - 129, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 71 5.2 Mounting positions Figure 5-10 Mounting positions for servo parallel shaft geared motors FZ.F and FD.F (flange- mounted design) and FZ.Z and FD.Z (housing flange design), frame size 29, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 72 Mounting positions for servo parallel shaft geared motors FZ.F and FD.F (flange- mounted design) and FZ.Z and FD.Z (housing flange design), frame sizes 39 - 129, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 73 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-12 Mounting positions for servo parallel shaft geared motors FZAD and FDAD, shaft- mounted design, frame size 29, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 74 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-13 Mounting positions for servo parallel shaft geared motors FZAD and FDAD, shaft- mounted design, frame sizes 39 - 129, 2 stage and 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 75: Bevel Geared Motor (2 Stage And 3 Stage: B And K)

5.2 Mounting positions 5.2.3 Bevel geared motor (2 stage and 3 stage: B and K) Figure 5-14 Mounting positions for servo bevel geared motor B, foot-mounted design, frame sizes 19 - 29, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 76 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-15 Mounting positions for servo bevel geared motor B, foot-mounted design, frame sizes 39 - 49, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 77 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-16 Mounting positions for servo bevel geared motor B.F (flange-mounted design) or B.Z (housing flange design) frame sizes 19 - 29, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 78 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-17 Mounting positions for servo bevel geared motor B.F (flange-mounted design) or B.Z (housing flange design), frame sizes 39 - 49, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 79 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-18 Mounting positions for servo bevel geared motors BAD, shaft-mounted design, frame sizes 19 - 29, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 80 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-19 Mounting positions for servo bevel geared motors BAD, shaft-mounted design, frame sizes 39 - 49, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 81 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-20 Mounting positions for servo bevel geared motor K, foot-mounted design, frame sizes 39 - 149, 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 82 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-21 Mounting positions for servo bevel geared motor K.F (flange-mounted design) and KAZ (housing flange design), frame sizes 39 - 149, 3 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 83 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-22 Mounting positions for servo bevel geared motor KAD, shaft-mounted design, frame sizes 39 - 149, 3-stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 84: Helical Worm Geared Motor

Features and mounting positions of the servo geared motors 5.2 Mounting positions 5.2.4 Helical worm geared motor Figure 5-23 Mounting positions for servo helical worm geared motor C, foot-mounted design, size 29, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 85 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-24 Mounting positions for servo helical worm geared motors C., foot-mounted design, frame size 39A, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 86 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-25 Mounting positions for servo helical worm geared motors C, foot-mounted design, frame sizes 49 - 89, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 87 M2-B M3-A M4-A M3-B M4-B M5-A M6-A M5-B M6-B Figure 5-26 Mounting positions for servo helical worm geared motor CF (flange design) and CAZ (housing flange design), frame size 29, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 88 M2-B M3-A M4-A M3-B M4-B M5-A M6-A M5-B M6-B Figure 5-27 Mounting positions for servo helical worm geared motor CF (flange design) and CAZ (housing flange design), frame size 39A, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 89 M4-A M3-B M4-B M5-A M6-A M5-B M6-B Figure 5-28 Mounting positions for servo helical worm geared motor CF (flange design) and CAZ (housing flange design), frame size 49 - 89, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 90 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-29 Mounting positions for servo helical worm geared motor CAD, shaft-mounted design, frame size 29, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 91 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-30 Mounting positions for servo helical worm geared motor CAD, shaft-mounted design, frame size 39A, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 92 Features and mounting positions of the servo geared motors 5.2 Mounting positions Figure 5-31 Mounting positions for servo helical worm geared motor CAD, shaft-mounted design, frame sizes 49 - 89, 2 stage SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 93: Mounting And Assembly

Risk of injury due to freely rotating parts Contact with rotating parts can result in serious or fatal injuries. • Do not touch any rotating parts. • Mount a cover cap or protective cover over freely rotating parts. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 94 An alarm must be output when the maximum permissible oil sump temperature is reached. The servo geared motor must be switched off when the maximum permissible temperature is exceeded. A machine can come to a standstill if the servo geared motor is shut down. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 95 • Ensure that no temperature-sensitive parts come into contact with hot surfaces. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 96: Installation Check List

1FG1 with shrink disks or SIMOLOC connection? (See chapter Mounting or removing the hollow shaft with shrink disk (Page 108) or Installing or removing the SIMOLOC connection (Page 112)) SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 97: Installation Instructions

The general tolerance for the tightening torque is 10 %. The tightening torque is based on a friction coefficient of μ = 0.14. Table 6-3 Tightening torque for fixing screws Thread size Tightening torque for property class in Nm 10.9 12.9 1000 1200 1 500 2 000 2 400 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 98 The values listed in the table "Tightening torque for screw plugs and valves" also apply to all completely metal valves, e.g. oil drain valves, vent valves. Plastic vent filters and oil sight glasses must be tightened "hand tight". SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 99: Installing A Servo Geared Motor With Foot Mounting

Parallel shaft Bevel gearbox Helical worm gearbox gearbox B, K FD/FZ Size 19, 29, 39 29, 39 B19, B29, B39 ‑ B49, K39, K49 39, 49 49, 59, 69 69, 79 K69, K79 79, 89 89, 109 K109 ‑ K129 K149 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 100: Flange Mounting A Servo Geared Motor

Mounting and assembly 6.5 Flange mounting a servo geared motor Flange mounting a servo geared motor Note Siemens AG recommends an anaerobic adhesive to enhance the friction lock between flange and mounting footprint. Table 6-6 Thread size of the fixing screws Thread size... - Page 101 Property class of the fixing screw/nut for DZ/ZZ and DF/ZF Gearbox size Flange Property class 19, 29, 39 A120 10.9 A140 10.9 A160 A200 A250 A300 109, 129 A350 1) Use suitable washers under the screw head/nut SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 102: Installing The Servo Geared Motor In A Foot Or Flange-Mounted Design

The second mounting option (foot or flange) is intended for add-on elements that do not transmit any force, e.g. protection covers with an intrinsic weight of up to max. 30% of the weight of the gearbox. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 103: Attaching Drive Or Output Elements To The Gearbox Shaft

Use the centering holes in the shaft end faces. Use a pulling-on device to attach input or output elements. Figure 6-1 Example of a pulling-on device SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 104 2. Heat the input or output elements, if provided. 3. Slide the drive input and output elements onto the shafts. 4. Secure the input or output elements, if provided. ❒ SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 105: Mounting The Protective Cover

When using the plastic protective cover for gearbox F49, the cover must first be brought into the correct shape. When using the plastic protective cover for other gearboxes, it is not necessary to bring the cover into the required shape; in this case, start with Point 2. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 106 4. Ensure that the O-ring or flat seal is correctly seated. ② 5. Screw on the protective cover with a tightening torque of 10‑15 Nm. 6. Protect all remaining bare areas with a suitable permanent corrosion protection agent. ❒ SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 107: Installing And Removing The Shaft-Mounted Gearbox

Figure 6-4 Mounting the hollow shaft with feather key Instead of the nut and threaded spindle shown in the diagram, other types of equipment such as hydraulic lifting equipment may be used. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 108 Damage to bearings and housing through impermissible forces when removing Inadmissible forces can occur when removing the hollow shaft via the gearbox housing, and can damage the bearings and housing. Remove the hollow shaft without stressing it or skewing it. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 109 Table 6-11 Dimensions for the threaded block and disk Gearbox Size Hollow shaft ∅ 19.9 22.5 B, C 19.9 22.5 B, F 24.9 24.9 B, K, F, C 29.9 34.9 39.9 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 110: Mounting Or Removing The Hollow Shaft With Shrink Disk

Mounting or removing the hollow shaft with shrink disk Mounting the hollow shaft with shrink disk Greased Absolutely grease-free ① Machine shaft ② Hollow shaft ③ Bushing Figure 6-6 Mounting the hollow shaft with shrink disk SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 111 The machine shaft material must comply with the following criteria in order to safely and reliably transfer the forces and torques: Elastic limit Re ≥ 360 N/mm Modulus of elasticity: Approx. 206 kN/mm Note The hollow shaft is axially secured on the machine shaft by means of a shrink disk connection. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 112 If they are not flush with one another when fitting, check the tolerance of the plug-in shaft. Greased Absolutely grease-free ① Outer ring ② Inner ring ③ Clamping screw ④ Hollow shaft ⑤ Machine shaft SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 113 2. Withdraw the shrink disk from the hollow shaft. ❒ Note Frame sizes 79 - 149: If the outer ring does automatically release from the inner ring, insert some of the clamping screws into the adjacent neighboring forcing-off threads. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 114: Installing Or Removing The Simoloc Connection

• Clean the bore of the hollow shaft and the machine shaft to remove any grease and other lubricants. • Do not use impure solvents and dirty cleaning cloths. • Do not use assembly paste at the force transmission point between the hollow shaft and the machine shaft. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 115 Oil type of the provided oil: CLP VG 68 DIN 51517‑3 Note ⑤ Place the pressure ring at the correct position as in the delivery state. Note ⑦ Before SIMOLOC assembly, mount the torque arms onto the gearbox. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 116 ⑪ Clamping screw for the clamping ring Protection cover / cover cap ⑤ ⑫ ⑩ Pressure ring Threaded hole for the clamping screw dur‐ ing disassembly ⑥ Hollow shaft SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 117 ④ Gearbox type Size Tolerance dimen‐ Thread size Tightening tor‐ sion to10 Property class 8.8 F, B, C 19, 29 0.6 ... 2.1 F, B, K, C 0.7 ... 2.2 F, B, K, C 0.8 ... 2.6 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 118 ⑨ Repeat the task until the tapered bushing has been freed. ⑩ 5. Remove screws ⑨ 6. Remove the tapered bushing ① 7. Lower the gearbox from the machine shaft ❒ SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 119: Mounting The Hollow Shaft With Splines

5. Replace the nut and the threaded spindle with a setscrew. Tighten the screw with the specified torque. ❒ Table 6-17 Tightening torque for setscrews Thread size Tightening torque in Nm SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 120: Torque Arms With Shaft-Mounted Gearboxes

We recommend using pretensioned, damping rubber elements. Mounting elements such as brackets, screws, nuts, etc. are not included in the scope of delivery. Figure 6-9 Mounting suggestion for torque arms on F.29 - F.149 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 121 Mount the torque arm bushing so that it is supported on both sides. Figure 6-10 Mounting suggestion for torque arm on foot and flange The torque arm can be fitted in various positions, depending on the hole circle pitch. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 122 1. Clean the contact surfaces between the housing and the torque arm. 2. Tighten the bolts to the specified torque. ❒ Table 6-19 Tightening torque for screws of property class 8.8 Thread size Tightening torque in Nm 2 600 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 123: Mounting The Oil Expansion Unit

K 129 - 149 B 39 - 49 C 69 – 89 Note Selecting the oil expansion unit Contact the Siemens Service Center for final selection of the oil expansion unit. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 124 Mounting the oil expansion unit, size 2 The unit is supplied as a mounting kit. The installation is described in the Compact Installation Instructions KA 2530-1 provided. Note Replace the vent valve of the unit yearly. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 125: Vibration Response

The vibration acceleration is evaluated in the frequency band from 10 to 2000 Hz. The maximum peak value in the time range is considered. To evaluate the vibration velocity, the measuring equipment must fulfill the requirements of ISO 2954. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 126 Mounting and assembly 6.11 Vibration response SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 127: Connecting

5. Take measures to prevent energy sources from being reconnected. 6. Ensure that the correct machine is completely interlocked. After you have completed the work, restore the operational readiness by following the above steps in the reverse order. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 128 • When connected to IT line systems, a monitoring device must signal the first fault between an active part and ground. Remove this fault immediately. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 129: Permissible Line System Types

TT line systems with grounded line con‐ ductor are predominantly used, which means that you must use an isolation transformer. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 130: Circuit Diagram

Connecting 7.3 Circuit diagram Circuit diagram Description Feeder cable Encoder Power Module Brake Motor Figure 7-1 Circuit diagram SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 131: System Integration

• Adapt the connecting cables to the type of use and the voltages and currents that occur. • Use prefabricated cables from SIEMENS (not in the scope of delivery). These cables reduce installation costs and increase operational reliability (see the Product Information). -

Page 132: Rotating The Connector At The Motor

Power connectors and signal connectors can be rotated to a limited extent. Use a suitable socket connector to rotate the angle plug. Unscrew and open the socket connector completely to avoid damaging the pin contacts. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 133 Angle α Angle β Connector size Drawing 1FG1□□□- 122° 208° □□C□□ 1FG1□□□- □□D□□ 135° 195° 1FG1□□□- □□E□□ 1FG1□□□- □□F□□ 1FG1□□□- □□G□□ 1FG1□□□- 195° 140° □□F□□ 1FG1□□□- □□G□□ SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 134 1FG1□□□- □□G□□ Table 7-4 Max. torque when rotating Connectors Max. torque when rotating Power connector M23 12 Nm Power connector M40 20 Nm Signal connector (without DRIVE-CLiQ) 12 Nm Signal connector (with DRIVE-CLiQ) 8 Nm SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 135: Routing Cables In A Damp Environment

The 1FG1 is equipped with the following power connectors depending on the size and power rating. Round connector M23 Round connector M40 Brake connection 24 V: "+" = BD1+; "-" = BD2- The power connectors can be rotated within a certain range. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 136: Signal Connection

• Comply with the EMC information provided by the manufacturer of the converter. The motor and the Motor Module are connected via a MOTION-CONNECT cable, see Instructions for handling the RJ45 connector (Page 140) SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 137: Motors Without A Drive-Cliq Interface

Motors without DRIVE-CLiQ require a Sensor Module Cabinet (SMC) for operation with a SINAMICS S120 drive system. The motor is connected to the SMC via a signal cable. The SMC is connected to the motor via a MOTION-CONNECT cable. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 138: Design Of The Signal Connectors

12 = B* 12 = B* 13 = R* 13 = data* 14 = D 14 = clock* 15 = M sensor 15 = M sensor SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 139: Connecting-Up A Converter

• To connect the motor to a converter, use MOTION-CONNECT cables or shielded connecting cables. Note The cable shielding should be braided and must have a high electrical conductivity. Braided shields made of copper or aluminum are well suited. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 140 , each cable separately shielded BD1+ and BD2- = brake cable without lettering, 1.5 mm , common shield PE = protective conductor Cable shield Conductor designations Recommended length of the cable ends: 105 mm SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 141 • Ensure a connection through a large surface area so that high-frequency currents are suitably discharged. Establish a 360° connection at the converter and at the motor, for instance using EMC cable glands at the cable entries. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 142: Instructions For Handling The Rj45 Connector

The DRIVE-CLiQ connection method with the RJ45 connector has the following components: DRIVE-CLiQ plug with RJ45 plug DRIVE-CLiQ socket with RJ45 socket ① Rotatable locking ring ② Tabs (2, opposite each other) ③ Latches (2, opposite each other) SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 143 ① The locking ring remains in the "locked" position. 3. Check that the two tabs are engaged in both latches on the socket and that the connector cannot be pulled out. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 144 The correct DRIVE-CLiQ connection is made when • the locking ring is in the "locked" position, • both tabs are engaged in both latches. You have now made a DRIVE-CLiQ connection. ❒ SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 145: Handling The Quick-Action Locking

Using SPEED-CONNECT, you can also connect cables with quick-release lock to the motor connector just the same as conventional cables with screw connectors (with full thread). Note We recommend cables with SPEED-CONNECT, as these are easier to handle. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 146 (position B). Minimum interlock Maximum interlock up to the end stop Note A secure connection is only guaranteed from position A onward. ❒ Releasing a SPEED-CONNECT connection Procedure SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 147 The triangles on the upper side of the connector must be located opposite to one another. 2. Withdraw the connector. Note Withdraw at the connector and not at the cable. ❒ SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 148 Connecting 7.4 System integration SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 149: Commissioning

Inadvertent starting of the converter can result in serious or fatal injuries. • Ensure that the converter is not inadvertently started. • Attach a warning plate at the location of the switch. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 150 Impermissible speeds can damage the 1FG1 motor. • Ensure that the maximum permissible operating speed is not exceeded. Implement this using a suitable closed-loop control or activate the speed monitoring function in the drive. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 151 If you operate a damaged servo geared motor, this can damage the winding or bearings and could even destroy the complete system. • Switch off the servo geared motor in case of uneven running or abnormal noise. • Identify the cause. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 152: Checklists For Commissioning

Have all touch protection measures for moving and live parts been installed and activated? Has the geared motor been mounted and aligned appropriately for the mounting posi‐ tion? SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 153 Checklist (8) - rolling bearing checks Check For servo geared motors that were stored, were the storage conditions according to Chapter "Storage" and the bearing replacement intervals according to Chapter "Bearing replacement intervals" complied with? SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 154: Preparing Commissioning

For gearboxes with long-term preservation and gearboxes supplied completely filled with oil. We recommend a complete oil change after a storage time longer than 24 months. 3. Mount an oil expansion unit. See Mounting the oil expansion unit (Page 121) ❒ SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 155: Commissioning Procedure

• Ensure that the converter is correctly parameterized. • When commissioning the servo geared motor, use the appropriate commissioning tool, e.g. "Drive ES" or "STARTER". • Follow the steps specified by the commissioning tool. ❒ SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 156: Switching On And Switching Off

3. Check the function of the safety equipment. 4. Check as to whether the servo geared motor achieves the required parameters. ❒ Switching off • Switch off the servo geared motor from the converter. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 157: Operation

The maximum torque is specified 2max on the rating plate (nameplate). Impermissible torques can result in gearbox damage. • Configure the control so that the maximum torque is not exceeded. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 158 If you operate a damaged servo geared motor, this can damage the winding or bearings and could even destroy the complete system. • Switch off the servo geared motor in case of uneven running or abnormal noise. • Identify the cause. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 159: Switching On And Switching Off

3. Check the function of the safety equipment. 4. Check as to whether the servo geared motor achieves the required parameters. ❒ Switching off • Switch off the servo geared motor from the converter. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 160: Operation

• Identify the cause. In operation, check the servo geared motor for: • Excessive operating temperature • Changes in gearbox noise • Possible leaks at the gearbox housing and shaft seals. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 161: Measures For Longer Non-Operational Periods

• Store the servo geared motor according to the instructions in chapter Storing the servo geared motor (Page 54). • Refer to the section Switching on and switching off (Page 154) before recommissioning. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 162 Operation 9.4 Measures for longer non-operational periods SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 163: Faults

Uneven running Significant motor temperature rise in no-load operation I Significant motor temperature rise under load J SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 164 Check the bearing and replace if necessary. fective. Defective gearing. Check the gearing and replace if necessary. Fixing screws loose. Tighten the screws, Thread sizes and tightening torques for fastening bolts (Page 170) SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 165 Flexible elements worn (e.g. on couplings). Replace flexible elements. If the fault still cannot be resolved after taking the measures listed above, please contact the manufacturer or the Siemens Service Center. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 166 Faults SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 167: Service And Maintenance

• Prevent oil from leaking • Remove any leaked oil immediately using a binding agent for oil or similar. • Eliminate the risk of slipping at the dangerous location. • Mark the dangerous location. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 168 When cleaning using compressed air, this can stir up dust, metal chips and cleaning agents, therefore leading to injuries. • When cleaning using compressed air, ensure that you use suitable extraction equipment and wear protective equipment such as safety goggles, protective suit, etc. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 169 • Never stand under suspended loads or in their slewing range. • After the servo geared motor has been placed down, ensure that it cannot roll. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 170: Inspection And Maintenance

• Perform the following maintenance measures as specified in the table. Maintenance and repair of the geared motor can be performed by Siemens Service Centers throughout the world. On this topic, contact your personalSIEMENS contact persons (http://www.siemens.com/... - Page 171 After 25 000 operating hours Replacement of the motor bear‐ On this topic, contact your person‐ ings, the encoder and the shaft alSIEMENS contact persons sealing ring on the motor side (http://www.siemens.com/ industry/contact) SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 172: Thread Sizes And Tightening Torques For Fastening Bolts

In the case of operating conditions specified by the operating company, the bearing service life for the bearings in the gearbox can be calculated with the help of the SIZER engineering tool. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 173: Checking And Changing Lubricants

Sealing plug Specified oil level Maximum oil level Minimum oil level Figure 11-1 Oil level in the gearbox Minimum and maximum permissible oil level Minimum permissible oil level: C = A - x SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 174: Checking The Oil Level Using The Oil Sight Glass (Optional)

Figure 11-3 Oil level in the oil sight glass ① Top up the oil level if necessary, and check it again. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 175: Checking The Oil Quality

• Change the oil completely. • If you use other oil types, flush the gearbox with the new oil. • Avoid contaminating the new oil. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 176 5. Check the state of the sealing ring on the sealing element. If the sealing ring is damaged, replace the sealing element with a new one. 6. After draining the oil, seal the gearbox immediately using the sealing element. ❒ SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 177 7. After flushing, seal the gearbox immediately using the sealing element. 8. Repeat this step for the second flushing. ❒ Filling in oil Note The required oil quantity is specified in Chapter "Oil quantities (Page 181)". SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 178: Recommended Oil Types

• Completely change the oil. • If you use other oil types, flush the gearbox using the new oil. • Avoid contaminating the new oil. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 179: Change The Roller Bearing Grease

Fuchs Renolit CX‑Tom 15 Foodstuff-compatible for the -30 °C to +60 °C Castrol Optileb GR UF 1 NSF H1 food industry Biologically degradable, for -35 °C to +60 °C Fuchs Plantogel 2 S agriculture, forestry and wa‐ ter industries Rolling bearing grease based on a semi-synthetic base oil SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 180: Service Life Of The Lubricants

"Guide values for oil change intervals". For a +80 °C oil sump temperature, when observing the properties specified by Siemens AG, the following service life can be expected: Table 11-4... -

Page 181: Recommended Lubricants

Use only lubricants with USDA (United States Department of Agriculture) H1 / H2 approval for deployment in the foodstuff or pharmaceutical industry. The released and recommended lubricants are listed in the table NT 7300 (https:// support.industry.siemens.com/cs/ww/en/view/109753864). SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 182 Use an approved gearbox lubricant from chapter "Recommended oil types (Page 176)". These oils have been tested and satisfy the requirements. Note Before use, check that the selected lubricating oil is still recommended by Siemens. Consult your Siemens representative, if applicable. SIMOTICS S-1FG1 servo geared motor...

-

Page 183: Oil Quantities

Due to the inherent principle of operation, oil mist can escape from a vent valve or labyrinth seal. Small quantities of oil or grease can escape at the shaft sealing ring during the run-in period of 24 hours. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 184: Cleaning The Servo Geared Motor

Switch off the power supply to the converter prior to cleaning. 11.2.6 Checking tightness of fastening bolts Note Replace unusable headless screws with headless screws of the same design and property class. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 185 • Switch off the power supply to the converter. • Check all fixing screws for tightness using a torque wrench. You will find the permissible torques in chapter Thread sizes and tightening torques for fastening bolts (Page 170) SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 186: Corrective Maintenance

11.3 Corrective maintenance 11.3 Corrective maintenance The Siemens Service Center in Bad Neustadt a. d. Saale handles or organizes the maintenance/ repair of servo geared motors along with other regional service and repair workshops. Contact your regional sales person about this. -

Page 187: Decommissioning And Disposal

• Prevent oil from leaking • Remove any leaked oil immediately using a binding agent for oil or similar. • Eliminate the risk of slipping at the dangerous location. • Mark the dangerous location. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 188 The machine comprises heavy individual components. When removing the servo geared motor, these components can fall. This can result in death or severe injuries and/or material damage. • Secure the machine components being removed to prevent them falling. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 189 • Avoid liquids coming into contact with the skin. Wear the appropriate personnel protection equipment, e.g. safety goggles, gloves. • Have materials on hand to remove leaked liquids and prevent areas from becoming slippery. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 190: Decommissioning

5. Transport the geared motor to a suitable location for storage and dismantling. ❒ 12.2.2 Dismantling the motor Note The rotor in a motor containing permanent magnets must only be removed by the manufacturer. Contact the Siemens Service Center (https://support.industry.siemens.com/cs/ww/en/). SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... -

Page 191: Disposal

For environmentally-friendly recycling and disposal of your old device, please contact a company certified for the disposal of waste electrical and electronic equipment, and dispose of the old device as prescribed in the respective country of use. SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 192 Decommissioning and disposal 12.3 Disposal SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 193: Appendix

Appendix Certificate for the "PS Premium" painting system from ECOLAB SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 194 Appendix A.1 Certificate for the "PS Premium" painting system from ECOLAB Figure A-1 Certificate_option_N16_page1 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

- Page 195 Appendix A.1 Certificate for the "PS Premium" painting system from ECOLAB Figure A-2 Certificate_option_N16_page2 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC...

-

Page 196: Ecolab Cleaning Recommendation

Appendix A.2 ECOLAB cleaning recommendation ECOLAB cleaning recommendation Figure A-3 ECOLAB cleaning recommendation for option N16 SIMOTICS S-1FG1 servo geared motor Operating Instructions, 12/2022, A5E47360747B/RS-AC... - Page 198 More information Siemens: www.siemens.com/simotics Industry Online Support (service and support): www.siemens.com/online-support Industry Mall: www.siemens.com/industrymall Siemens AG Digital Industries Motion Control Postfach 31 80 91050 ERLANGEN Germany Scan the QR code for more informa- tion about SIMOTICS.