Table of Contents

Advertisement

Quick Links

Technical Reference Guide

Product Overview

Describes features of the product.

Setup

Describes setup and installation of the product and

peripherals.

Advanced Usage

Describes advanced usage methods for the product.

Application Development Information

Describes how to control the printer and necessary

information when you develop applications.

Handling

Describes how to handle the product.

Troubleshooting

Describes actions to take when a trouble occurs.

Replacement of the TM-H6000V

Describes precautions for replacement.

Appendix

Describes general specifications and character code tables.

M00159200

Rev. A

Advertisement

Table of Contents

Summary of Contents for Epson TM-H6000VI

- Page 1 Technical Reference Guide Product Overview Describes features of the product. Setup Describes setup and installation of the product and peripherals. Advanced Usage Describes advanced usage methods for the product. Application Development Information Describes how to control the printer and necessary information when you develop applications.

- Page 2 • Neither is any liability assumed for damages resulting from the use of the information contained herein. • Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of: accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s operating and...

-

Page 3: For Safety

For Safety Key to Symbols The symbols in this manual are identified by their level of importance, as defined below. Read the following carefully before handling the product. You must follow warnings carefully to avoid serious bodily injury. WARNING Provides information that must be observed to prevent damage to the equipment or loss of data. •... -

Page 4: Cautions

Cautions • Be sure to set this equipment on a firm, stable, horizontal surface. Product may break or cause injury if it falls. • Do not use in locations subject to high humidity or dust levels. Excessive humidity and dust may CAUTION cause equipment damage or fire. -

Page 5: Restriction Of Use

Open Source Software License This product uses open source software in addition to Epson proprietary software. For information of the open source software used in this product, see the following URL. -

Page 6: About This Manual

About this Manual Aim of the Manual This manual provides developers/engineers with all the necessary information for design, development and installation of a POS system, and also design and development of a printer application. Manual Content The manual is made up of the following sections: Chapter 1 Product Overview Chapter 2... -

Page 7: Table Of Contents

Contents ■ For Safety..........................3 Key to Symbols..................................3 Warnings ....................................3 Cautions....................................4 ■ Caution Labels .........................4 ■ Restriction of Use ........................5 ■ Open Source Software License.....................5 ■ About this Manual ........................6 Aim of the Manual ................................6 Manual Content .................................. 6 ■... - Page 8 Setup .......................32 ■ Flow of Setup ........................32 ■ Removing the Protective Materials and Tape..............33 ■ Connecting the AC adapter....................34 Connecting the AC adapter............................34 ■ Connecting the Printer to the Host................... 36 USB Type-B Interface...............................36 Ethernet Interface ................................36 Wireless LAN Interface..............................39 Serial Interface ..................................42 USB PlusPower Interface..............................43...

- Page 9 Setting and reference items for Ethernet ........................76 Setting and reference items for Wi-Fi........................77 ■ MAC Address Confirmation....................78 ■ Setting/Checking Modes ....................79 Self-test Mode ...................................81 NV Graphics Information Print Mode........................82 Receipt Enhancement Information Print Mode ....................83 Software Setting Mode ..............................84 Restore Default Values Mode............................86 Interface Setup Mode..............................87 TM-Intelligent Settings Information Print Mode ....................87...

- Page 10 Handling ...................... 102 ■ Installing and Replacing the Roll Paper................. 102 ■ Inserting Slip Paper ......................104 ■ Inserting Validation Paper....................105 ■ Cleaning the Product......................106 Cleaning the Printer Case............................106 Cleaning the Thermal Head and the Platen Roller .................... 106 Cleaning the MICR Head.............................

- Page 11 Replacement of the TM-H6000V ............... 126 ■ Compatibility ........................127 Printing ..................................... 127 Print Density..................................127 Printable Area ................................. 127 Cutting Method ................................127 Receive Buffer................................. 127 Memory Capacity ................................128 Electrical Characteristics............................. 128 DIP Switches..................................128 Printer Status .................................. 128 Logo Registration................................

- Page 12 ■ Bluetooth Low Energy Technology Advertising............160 Introduction ..................................160 Dongle specifications ..............................160 Procedure..................................160 Changing the Bluetooth Low Energy Technology Advertising Packet............161 ■ Character Code Tables....................... 172...

-

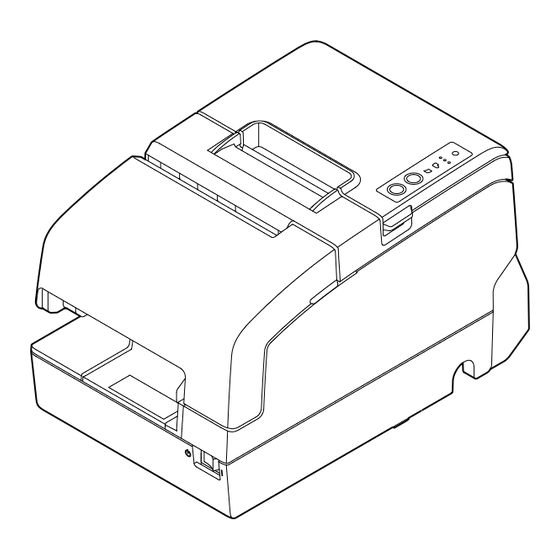

Page 13: Product Overview

• Supports status notification function, which enables the printer to send its status to a web server at regular intervals. • ESC/POS Command System. • OPOS ADK, OPOS ADK for .NET, JavaPOS ADK, and EPSON Advanced Printer Driver (APD). • Bar code and two-dimensional symbol printing. - Page 14 • Supports printing using multiple interfaces. • Enables HTTPS communication. • A maintenance counter function is supported. • Connect the Laird Connectivity BT-820 to support iBeacon. Others • Small footprint and simple design. • Direct connection of Epson customer display series (DM-D) is possible.

-

Page 15: Product Configurations

Chapter 1 Product Overview Product Configurations Models Function Model Name MICR Endorsement printer (E/P) Validation Standard model – – – ✓ MICR model – – ✓ ✓ MICR/Endorsement model – ✓ ✓ MICR/Validation model – NFC Tag You can select the printer you want to use by simply placing an NFC device over the NFC tag (mark) on the printer. - Page 16 Chapter 1 Product Overview • LED information label * • Ink ribbon cartridge ERC-32(B) • Ink ribbon cartridge ERC-43(B) * * May not be included depending on the model. Options • TA-6000II: Printer attachment. • OT-DC6000: Cover for protecting the wireless LAN unit. •...

-

Page 17: Part Names And Functions

Chapter 1 Product Overview Part Names and Functions NFC tag* A mark is printed here to indicate the position of the NFC tag. To establish communication with an NFC device, bring the device close to this mark. For the functions using the NFC tag, refer to "Useful Functions for Smart Devices"... -

Page 18: Control Panel

Chapter 1 Product Overview Control Panel On when the printer is on. (Power) LED (Error) LED The 3 LEDs indicate an error status. (See "Status and Errors" on page 21.) (Paper) LED On when the roll paper is near its end. (Slip) LED On when the printer is in slip paper mode. -

Page 19: Connectors

Chapter 1 Product Overview Connectors All connectors are located on the lower rear of the printer. Serial interface connector* For connecting a serial cable for connecting to a computer. *May not be equipped depending on the printer model. USB PlusPower connector* For connecting a USB PlusPower cable for connecting to a computer. -

Page 20: Online And Offline

Chapter 1 Product Overview Online and Offline Online The printer is online and ready for normal printing unless there is a reason to go offline. Offline The printer automatically goes offline under the following conditions: • While the printer power is turning on/off •... -

Page 21: Status And Errors

• You can scan the QR code using your smart device to check detailed information about the error and the solution. https://support.epson.net/p_doc/928/ You cannot identify the error by the flashing patterns of the LEDs. Develop the application so that users can identify the error description and check the solutions. -

Page 22: Printer Operating Status

Chapter 1 Product Overview Printer operating status Error LED Power Slip Paper Status Solution and Reference The power is off or is not Make sure the power supply is being supplied connected to the printer and then turn on the printer. Online (Nomal status) Roll paper near end The roll paper will run out soon. -

Page 23: Error Status

Chapter 1 Product Overview Error LED Power Slip Paper Status Solution and Reference Overwriting firmware Th e p r in te r f ir mw a re over w r i te process is in progress. Wait until the printer restarts. CAUTION: Do not turn off the power while the firmware over write process is in... - Page 24 The RTC (Real Time Clock) Use a USB cable to connect the printer battery has run out. to the computer and then use the TM-H6000VI Utility to set the time. For more information about the TM-H6000VI Utility, see the TM-H6000VI Utility User's Manual.

- Page 25 Chapter 1 Product Overview Error LED Power Slip Paper Status Error Description Mechanical operation error Could not detect the position of the p l a t e n r o l l e r o p e n i n g / c l o s i n g mechanism.

-

Page 26: Nv Memory

To register your graphics data, use TM-H6000VI Utility or ESC/POS commands. You can check registered graphics data using TM-H6000VI Utility or by printing the data in the NV graphics information print mode. -

Page 27: Maintenance Counter

Chapter 1 Product Overview Maintenance Counter With this function, printer information, such as the number of lines printed, the number of autocuts, and printer operation time after the printer starts working, is automatically stored in NV memory. • You can also check the head running length and number of times of autocutting with the self-test (see "Self-test Mode"... -

Page 28: Simple Setup For Wireless Lan

Chapter 1 Product Overview Simple Setup for Wireless LAN The printer has "SimpleAP" mode that allows a device to directly connect to the printer without using an access point. This makes it easy to set up a printer to connect to a wireless LAN using the printer setting tool, without having to go through a network environment such as an access point. -

Page 29: About Simpleap

• The printer can be connected to Wi-Fi Direct and a wireless LAN or a wired LAN at the same time. • Wi-Fi Direct settings can be checked or changed using Web Config or TM-H6000VI Utility. For details, check the Web Config Reference Guide or the TM-H6000VI Utility User's Manual. -

Page 30: Useful Functions For Smart Devices

Chapter 1 Product Overview Useful Functions for Smart Devices You can easily connect this product to the network by using the NFC tag built-in to the printer or the QR code printed on the status sheet. NFC Tag Bring a smart device that supports NFC close to the NFC tag to acquire the printer information (information for specifying the device). -

Page 31: Printing Using Multiple Interfaces

Chapter 1 Product Overview Printing Using Multiple Interfaces In printers with multiple interfaces, you can use all interfaces without any limitations on which interface is to be used. You can use this function to temporarily connect a smart device to a nearby printer and print. The printer provides each interface with an independent receive buffer and switches the active interface depending on the priority, while handling data in each receive buffer. -

Page 32: Setup

Chapter 2 Setup Setup This chapter describes setup and installation of the product and peripherals. Flow of Setup This chapter consists of the following sections along with the setup flow of the product and peripherals. Removing the Protective Materials and Tape (page 33) Connecting the AC adapter (page 34) Connecting the Printer to the Host (page 36) Connecting the Cash Drawer (page 44) -

Page 33: Removing The Protective Materials And Tape

Chapter 2 Setup Removing the Protective Materials and Tape Protective materials and tape are applied for protection against impacts during transportation. Remove all of them, from A to K. To remove protective material J, you must open the receipt unit. -

Page 34: Connecting The Ac Adapter

Chapter 2 Setup Connecting the AC adapter Use the Epson PS-190 or an equivalent product as the AC adapter. • Never insert the AC cable plug into a socket that does not meet the input voltage of the AC adapter. - Page 35 Chapter 2 Setup Connect the DC cable to the printer. Insert the AC cable plug into a power outlet. Set the AC adapter so that its label side is facing down.

-

Page 36: Connecting The Printer To The Host

Ethernet Interface Use LAN cable to connect the printer to the network via a hub. Use Web Config or TM-H6000VI Utility to set network. • When LAN cables are installed outdoors, make sure they are connected through devices that have surge protection. - Page 37 Chapter 2 Setup Setting up using Web Config Open the web application installed in the printer from a web browser to configure the settings. Since you need to enter the IP address of the printer to open the web application, set the network segment of your computer to the same as the printer.

- Page 38 Web Config screen will not be displayed. To reconnect from the computer, change its network settings so that the network segment is the same as the printer. Setting up using TM-H6000VI Utility Refer to TM-H6000VI Utility User's Manual.

-

Page 39: Wireless Lan Interface

"Setup using Web Config" on page 40 Method2: Setup using TM-H6000VI Utility Refer to TM-H6000VI Utility User's Manual. • When using wireless LAN, make sure you disconnect the LAN cable. If a LAN cable is connected, wireless LAN is disabled. - Page 40 Chapter 2 Setup Setup using Web Config Necessary Items Prepare the following items. A device for the setup which has a web browser. When the printer is turned on during the following conditions, the SimpleAP mode is automatically activated and the "SimpleAP Start" sheet and guidance are printed. In this case, start the setup from step 4. •...

- Page 41 Chapter 2 Setup Scan the QR code on the "SimpleAP Start" sheet with the device for setup and connect it to the printer. If the device cannot scan the QR code, open the Wi-Fi settings screen of the device, select the SSID printed on the "SimpleAP Start"...

-

Page 42: Serial Interface

Connecting the Optional Wireless LAN Unit With the optional wireless LAN unit, the printer can be used with a Wi-Fi connection. The setting can be changed using TM-H6000VI Utility, or in the software setting mode. See "Software Settings" on page 66 for more details. -

Page 43: Usb Pluspower Interface

Chapter 2 Setup USB PlusPower Interface When using a USB PlusPower cable to connect with the host device, connect the flat connector of the USB PlusPower cable to the printer, and the square connector to the device. After starting the host device, turn the printer on. -

Page 44: Connecting The Cash Drawer

Chapter 2 Setup Connecting the Cash Drawer • Two driver transistors cannot be energized simultaneously. • Leave intervals longer than 4 times the drawer driving pulse when sending it continuously. Required specifications of cash drawer Specifications of drawers differ depending on manufacturer and/or model. When you use a drawer other than specified, make sure its specification meets the following conditions. -

Page 45: Connecting The Drawer Kick Cable

Chapter 2 Setup Pin assignments Pin number Signal name Direction Frame GND Drawer kick drive signal 1 Output Drawer kick open/close signal Input +24 V Drawer kick drive signal 2 Output 6 5 4 3 2 1 Signal GND Connecting the drawer kick cable •... -

Page 46: Connecting The Optional Customer Display

Chapter 2 Setup Connecting the Optional Customer Display • This product cannot be connected to a USB-connected customer display and serial-connected customer display at the same time. • Dip Switch 2-2 can be toggled to connect to the customer display via USB or serial. •... -

Page 47: Attaching And Removing The Connector Cover

Chapter 2 Setup Attaching and Removing the Connector Cover Follow the steps below to attach the connector cover to protect cables. Align the 2 protrusions on the top of the connector cover with the holes in the back of the printer. Push the connector cover forward so that the protrusions at the bottom of the printer fit properly in the holes in both sides of the connector cover. -

Page 48: Installing And Replacing The Ribbon Cartridge (Erc-32)

Chapter 2 Setup Installing and Replacing the Ribbon Cartridge (ERC-32) Be sure to use the specified ribbon cassette. (see "Product Specifications" on page 132) Turn the knob on the ribbon cartridge a little in the direction of the arrow marked on the cartridge to remove any slack in the ribbon. - Page 49 Chapter 2 Setup Open the front cover. Remove the used ribbon cartridge, if there is one. Insert a new ribbon cartridge until it clicks into place. Turn the knob on the cartridge in the marked direction again to remove any slack in the ribbon.

-

Page 50: Installing And Replacing The Ribbon Cartridge For Endorsement Printing (Erc-43)50

Chapter 2 Setup Installing and Replacing the Ribbon Cartridge for Endorsement Printing (ERC-43) If your printer is equipped with an endorsement printer, endorsement printing on slip paper is available. Follow the steps below to install/replace the ribbon cartridge for the endorsement printer. (see Be sure to use the specified ribbon cassette. - Page 51 Chapter 2 Setup Open the receipt unit. Remove the used ribbon cartridge, if there is one. Insert a new ribbon cartridge until it clicks into place.

- Page 52 Chapter 2 Setup Turn the knob on the cartridge in the marked direction again to remove any slack in the ribbon. Close the receipt unit.

-

Page 53: Installing The Roll Paper

Chapter 2 Setup Installing the Roll Paper Be sure to use the certified paper. Follow the steps below to install the roll paper. Make sure the printer is turned on. Open the roll paper cover. Insert the roll paper in the correct direction. - Page 54 Chapter 2 Setup Pull out some paper, and close the roll paper cover. Tear off the paper with the manual cutter.

-

Page 55: Test Printing

Chapter 2 Setup Test Printing After the printer setup or when the printer is not operating correctly, you can check the printer operation with test printing. If the printer performs pattern printing following the steps below, the printer is operating normally. -

Page 56: Test Printing On Validation Paper

Chapter 2 Setup Test Printing on Validation Paper Insert the roll paper and close all the covers. While pressing the (Feed) and (Release) buttons, turn on the printer. (Press and hold the (Feed) and (Release) buttons until the (Slip) LED flashes.) After the (Slip) LED flashes, insert the slip paper. -

Page 57: Attaching The Power Switch Cover

Chapter 2 Setup Attaching the Power Switch Cover By attaching the power switch cover, you can prevent accidental operations of the power switch. You can turn on and off the power switch by inserting a pointed object in the holes on the power switch cover. To detach the cover, use a pointed object. -

Page 58: Applying The Led Information Label

Chapter 2 Setup Applying the LED Information Label You can use the LED information label to swiftly learn the status of the printer when an error occurs. Check the printer's LED on/flashing pattern and identify the error type from the LED information label. Or, you can scan the QR code using your smart device to check detailed information about the error and the solution. - Page 59 Chapter 2 Setup Apply the LED information label in the position in the figure below.

-

Page 60: Rtc Settings

RTC may run out of charge and require reconfiguration. If the time is initialized, make settings using the Setup Utilities. For details on making settings using the Setup Utilities, see the TM-H6000VI Utility User's Manual. -

Page 61: Adjusting The Paper Roll Near-End Sensor

Chapter 2 Setup Adjusting the Paper Roll Near-End Sensor Below are two situations where a roll paper NE sensor adjustment is required. • To adjust the detection position to suit the diameter of the roll paper core used. • To adjust the detection position of remaining amount of paper. •... -

Page 62: Advanced Usage

Chapter 3 Advanced Usage Advanced Usage Setting the DIP Switches On this printer, you can make various settings with DIP switches. The DIP switches are already set for the current interfaces. Change the setting if necessary. Functions of the DIP switches differ depending on the interface. Setting Procedure Follow the steps below to change the DIP switch settings. -

Page 63: When A Serial Interface Is Connected

Chapter 3 Advanced Usage When a Serial Interface is Connected DIP Switch Bank 1 Default Function setting Data reception error Ignored Prints "?" Reserved (Do not change settings) Fixed to OFF Handshaking XON/XOFF DTR/DSR Word length 7 bits 8 bits Parity check Parity selection Even... -

Page 64: When Another Interface Is Connected

Chapter 3 Advanced Usage When Another Interface is Connected DIP Switch Bank 1 Default Function setting 1-1–1-2 Reserved (Do not change settings) Fixed to OFF Reserved 1-4– Reserved (Do not change settings) Reserved DIP Switch Bank 2 Default Function setting •... -

Page 65: Selecting The Print Density (Dip Switches 2-3/2-4)

Chapter 3 Advanced Usage Selecting the Print Density (DIP Switches 2-3/2-4) Function SW 2-3 SW 2-4 Do not set Print density (standard) Print density (medium) Print density (dark) • If the print density is set to "Medium" or "Dark" level, print speed may be reduced. •... -

Page 66: Software Settings

The settings can be made in any of the methods listed in the table below or by using the ESC/POS commands. For an explanation of each function and setting, see "Overview of Each Function" on page TM-H6000VI Software Item\Method Utility for... - Page 67 "Software Setting Mode" on page • For detailed information about ESC/POS commands, see the Product Specifications. Product Specifications is available after contracting the non-disclosure agreement with Epson. For details, please contact the selling agency. • The name for [Item/Method] might differ from what is shown in Software Setting Mode or...

-

Page 68: Overview Of Each Function

Chapter 3 Advanced Usage Overview of Each Function Print Density Monochrome Selectable from 70% to 130% (5% increment) Initial setting: Depends on the Dip Switch Depending on the paper type, it is recommended to set the print density as shown in the table below for the best print quality. - Page 69 Chapter 3 Advanced Usage Lower Margin • Enable • Disable (initial setting) Blank Line Spacing • 25% • 50% • 75% • Not Reduce (initial setting) Blank Space • 25% • 50% • 75% • Not Reduce (initial setting) Barcode Height •...

- Page 70 Chapter 3 Advanced Usage Default International Character Set Selectable from 18 sets Initial setting: USA Embedded Font Replacement Font A Replacement • Font A (No Replacement) • Font B • Font C Font B Replacement • Font A • Font B (No Replacement) •...

- Page 71 Chapter 3 Advanced Usage • 57600 bps • 115200 bps Priority is given to the settings for DIP switches 1-7 and 1-8. When configuring these settings in Software Settings, set DIP switches 1-7 and 1-8 to OFF. USB Interface Settings USB power-saving function •...

- Page 72 • Level 1 (Low) • Level 2 • Level 3 (High) (initial setting) Other Settings Printer Model • TM-H6000VI (initial setting) • TM-H6000IV • TM-H6000V Column Emulation • 42 column mode (standard column mode) (initial setting) • 46 column mode...

- Page 73 Chapter 3 Advanced Usage • 192 KB NV Graphics Memory • None (0 KB) • 64 KB • 128 KB • 192 KB • 256 KB • 320 KB • 384 KB (initial setting) LED indicator when I/F starting • Enable •...

-

Page 74: Setting And Reference Items Shared By Ethernet/Wi-Fi

Chapter 3 Advanced Usage Setting and reference items shared by Ethernet/Wi-Fi TM-H6000VI Status Web Browser Default Utility Sheet Item Parameter setting Reference Setting Reference Setting Reference ✔ ✔ ✔ MAC Address ✔ ✔ ✔ ✔ ✔ IP Address 192.168.192.168 ✔... - Page 75 Chapter 3 Advanced Usage TM-H6000VI Status Web Browser Default Utility Sheet Item Parameter setting Reference Setting Reference Setting Reference ✔ ✔ ✔ ✔ Community (Up to 32 " " (no value) Name characters) (read/write) ✔ ✔ ✔ ✔ Wellknown Enable/Disable...

-

Page 76: Setting And Reference Items For Ethernet

Chapter 3 Advanced Usage Setting and reference items for Ethernet TM-H6000VI Status Web Browser Default Utility Sheet Item Parameter setting Reference Setting Reference Setting Reference ✔ ✔ ✔ ✔ ✔ Communication Auto Negotiation / Auto negotiation mode setting 10BASE-T Half /... -

Page 77: Setting And Reference Items For Wi-Fi

Chapter 3 Advanced Usage Setting and reference items for Wi-Fi TM-H6000VI Status Web Browser Default Utility Sheet Item Parameter setting Reference Setting Reference Setting Reference ✔ ✔ ✔ ✔ ✔ SSID (Up to 32 EpsonNet characters) ✔ ✔ WPA/WPA2 Pre- 8-63 ASCII charac- "... -

Page 78: Mac Address Confirmation

Chapter 3 Advanced Usage MAC Address Confirmation You can check the printer's MAC address using the following procedures. • Printing the status sheet • Printing the self-test • Using a Web browser to confirm (Web Config function) -

Page 79: Setting/Checking Modes

Chapter 3 Advanced Usage Setting/Checking Modes As well as print mode, the following modes are also provided for making various printer settings and checking items. • Self-test mode • NV Graphics Information • Receipt Enhancement Information • Software Settings • Restore Default Values •... - Page 80 Chapter 3 Advanced Usage In 1 and 2, the following guidances are printed, the Paper LED flashes, and instructs the user's operations. 1. Continuing self-test guidance 2. Mode selection guidance...

-

Page 81: Self-Test Mode

Chapter 3 Advanced Usage Self-test Mode You can check the following items using the self-test. • Printer Name • Printer Firmware Version • Product Serial number • Interface type • Condition for BUSY • Resident fonts • Whether the automatic line feed function is enabled or not •... -

Page 82: Nv Graphics Information Print Mode

Chapter 3 Advanced Usage NV Graphics Information Print Mode Prints the following NV graphic information registered to the printer. • Capacity of the NV graphics • Used capacity of the NV graphics • Unused capacity of the NV graphics • Number of NV graphics that are registered •... -

Page 83: Receipt Enhancement Information Print Mode

Chapter 3 Advanced Usage Receipt Enhancement Information Print Mode You can check the following items using the R/E information mode: • Automatic top logo setting • Automatic bottom logo setting • Extended settings for automatic top/bottom logo Follow the steps below. After running a self-test, hold down the Feed button for at least one second, and then select the Mode selection. -

Page 84: Software Setting Mode

Chapter 3 Advanced Usage Software Setting Mode Set the printer's memory switches and customized values. "Software Settings" on page 66 for information about available functions and settings and how to set them. You can also make the software settings using the ESC/POS commands. Follow the steps below. - Page 85 Chapter 3 Advanced Usage After briefly pressing the Feed button (less than one second) for the number of times shown in the print result, hold down the button for more than one second to select the setting items. The setting selected as the setting item, the current settings and default settings are printed. Depending on the setting item, you may need to continue selecting the setting item before the settings are printed.

-

Page 86: Restore Default Values Mode

Chapter 3 Advanced Usage Restore Default Values Mode In Restore default values mode, following values saved on NV Memory will be set back to default settings. When any error occurs, you can use to specify the reason. Restore default settings Restore default settings and Delete definition Setting Contents... -

Page 87: Interface Setup Mode

Chapter 3 Advanced Usage Interface Setup Mode Use this mode to setup the interface and other settings. Follow the steps below. After running a self-test, hold down the Feed button for at least one second to enter the Mode selection. The Mode selection guidance is printed, and the Paper LED flashes. -

Page 88: Peripheral Device Information Print Mode

Chapter 3 Advanced Usage Peripheral Device Information Print Mode This function allows you to print information for the device currently connected to the printer. • Customer Display information • Wi-Fi adapter information Follow the steps below. After running a self-test, hold down the Feed button for at least one second to enter the Mode selection. -

Page 89: Hexadecimal Dumping Mode

Chapter 3 Advanced Usage Hexadecimal Dumping Mode In hexadecimal dumping mode, data from the host device is printed in hexadecimal numbers and characters. By comparing the print outs and the program, you can check whether or not data is being sent to the printer correctly. -

Page 90: Printing A Status Sheet

Chapter 3 Advanced Usage Printing a Status Sheet Print the interface settings. • After the status sheet is printed, only the print settings of the mainly connected interface are retained. For the mainly connected interface, see "Printing Using Multiple Interfaces" on page •... - Page 91 Sever access test result Check Network Connection FAIL Ethernet Cable Connection NG IP Address Check Unchecked Detailed IP Setup Check Unchecked Network Status Printer Name XXXXXXXX Printer Model TM-H6000VI Series IP Address XXX.XXX.XXX.XX Subnet Mask XXX.XXX.XXX.X Default Gateway X.X.X.X MAC Address XX:XX:XX:XX:XX:XX...

- Page 92 Chapter 3 Advanced Usage Example of Printing During Recoverable Errors or When Waiting for Paper Removal (Slip) A status sheet for Slip printer is printed if the power is turned on during paper removal standby. If this occurs, remove the slip paper. If paper is not set, refer to "Slip paper is jammed"...

-

Page 93: Resetting The Interface Settings

Chapter 3 Advanced Usage Resetting the Interface Settings Follow the steps below to restore the interface settings to the factory default. • The interface settings can also be initialized from the Interface Setup Mode. See "Interface Setup Mode" on page 87 for more details •... -

Page 94: Tm-Intelligent Function

• Server direct print • Status Notification You can set each function in the Setup Utilities. For details on the setting method for TM-H6000VI Utility, see the TM-H6000VI Utility User's Manual. You can also download a dedicated manual and sample programs from our website. -

Page 95: Web Config

Chapter 3 Advanced Usage Web Config Web Config is a printer's built-in web page that allows you to check and change printer settings on your browser. To use Web Config, you need to set your computer's IP address to the same segment as the printer. How to Start Web Config Start your web browser on a computer or smart device on the network and enter the IP address of the printer in the address field. -

Page 96: Application Development Information

• Server Direct Print ePOS-Print XML ePOS-Print XML is the Epson original control command system for POS printers defined in XML. With ePOS- Print XML commands, you can print in environments where HTTP communication is available and from OS applications. For detailed information about ePOS-Print XML, see the "ePOS-Print XML User's Manual". -

Page 97: Controlling The Cash Drawer

Register a cash drawer using the SetupPOS Utility, and control using the OpenDrawer method or the DirectIO function. For details, see the "EPSON OPOS ADK for .NET MANUAL Application Development Guide Cash Drawer (EPSON Standard)" and the "UnifiedPOS Specification". JavaPOS Register a cash drawer using the SetupPOS Utility, and control using the OpenDrawer method or the DirectIO function. -

Page 98: Software

Because controlling POS peripherals with original commands is not required on the application side, efficient system development is possible. EPSON OPOS ADK for .NET The OPOS ADK for .NET is a POS industry standard printer driver compatible with Microsoft POS for .NET. It allows you to develop applications that are compatible with the UPOS (Unified POS) specification. -

Page 99: Drivers

ESC/POS commands is also attached to this driver. EPSON TM Virtual Port Driver This is a serial/parallel-USB/LAN conversion driver to make an Epson Windows TM/BA/EU printer connected via USB or LAN accessible from a POS application through a virtual serial or parallel port. -

Page 100: Others

Chapter 4 Application Development Information Epson Monitoring Tool Use to check a list of status for the Epson printers connected to the Windows network. You can also update certificates for multiple printers used for WPA-Enterprise/WPA2-Enterprise in a batch. BmpToRaster You can convert BMP image files to multi tone or black and white print Windows command data. -

Page 101: Precautions When Developing Applications

Chapter 4 Application Development Information Precautions when Developing Applications This section describes information that you should be aware of when developing systems and applications using this product. Minimum Paper Length when Cutting When printing short in the vertical direction of the paper, cut the paper at least 20 mm {0.79 in} away from the previous cutting position. -

Page 102: Handling

Chapter 5 Handling Handling This chapter describes basic handling of the printer. • Be sure to use the certified paper. ("Paper Specifications" on page 138) • Do not insert any paper that has clips or staples. This may cause paper jams and damage. •... - Page 103 Chapter 5 Handling Pull out some paper, and close the roll paper cover. Tear off the paper with the manual cutter.

-

Page 104: Inserting Slip Paper

Chapter 5 Handling Inserting Slip Paper Models with an MICR reader use a permanent magnet. Do not bring a magnetic card or the like near the product. CAUTION When printing on slip paper, follow the steps below to insert the paper. If your printer is equipped with a MICR reader, MICR reading is available by inserting the check paper so that the MICR characters on the paper are on the right side. -

Page 105: Inserting Validation Paper

Chapter 5 Handling Inserting Validation Paper When printing on validation paper using validation function, follow the steps below to insert the paper. Make sure the printer is turned on. Insert the paper with the right paper edge against the right side of the paper guide at the printer top, and insert it as far as it will go. -

Page 106: Cleaning The Product

Cleaning the Thermal Head and the Platen Roller Epson recommends cleaning the thermal head periodically (generally every 3 months) to maintain receipt print quality. Depending on the roll paper used, paper dust may stick to the platen roller and the paper may not be fed correctly. -

Page 107: Cleaning The Micr Head

Chapter 5 Handling Cleaning the MICR Head If your printer is equipped with a MICR reader, when the MICR head becomes dirty, the printer cannot read MICR characters normally. Approximately every year, clean the MICR head with the following or an equivalent commercially available cleaning sheet: KICTeam, Inc. -

Page 108: Preparing For Transport

Chapter 5 Handling Preparing for Transport Follow the steps below to transport the printer. Turn off the printer. Confirm that the Power LED is off. Disconnect the AC cable plug from a power outlet. Remove the roll paper. Pack the printer upright. -

Page 109: Troubleshooting

If the trouble cannot be resolved, the product will need to be repaired. • Identify trouble, and take the necessary actions, according to the LED pattern that is displayed. "Status and Errors" on page https://support.epson.net/p_doc/928/ • Identify trouble based on the symptoms, and take the appropriate actions. Trouble... -

Page 110: Print Quality Problem

Chapter 6 Troubleshooting Print Quality Problem Print Quality Problem (Receipt printer) Vertical white streaks Cause Solution and reference The head is dirty. Perform head cleaning. "Cleaning the Thermal Head and the Platen Roller" on page 106. Noticeable print shading/White lines are present Cause Solution and reference The print speed fluctuates or... - Page 111 Chapter 6 Troubleshooting The print color is too light Cause Solution and reference The ink ribbon color is too light. Replace the ink ribbon. "Installing and Replacing the Ribbon Cartridge (ERC-32)" on page "Installing and Replacing the Ribbon Cartridge for Endorsement Printing (ERC- 43)"...

-

Page 112: Setting Slip Paper Does Not Start Printing

Chapter 6 Troubleshooting Setting slip paper does not start printing Check the Slip LED. Slip LED is flashing continuously Cause Solution and reference The slip paper is set in a incorrect Check whether the slip paper is inserted straight along the paper guide. position. -

Page 113: Slip Led Does Not Change From Flashing To Lit Up

The sensor does not detect any paper. Download the Slip Paper Sensor Adjustment Tool (Windows only), and adjust the sensitivity of the Slip paper sensor (A in the illustration). Refer to the "Epson TM-H6000VI Slip Paper Sensor Adjustment Tool User's Manual" for adjustment procedures. -

Page 114: Even When Slip Paper Is Set, Paper Is Fed And An Error Occurs

Chapter 6 Troubleshooting Even when slip paper is set, paper is fed and an error occurs Cause Solution and reference The paper being used does not match Check the printer driver settings. the printer driver settings. Slip LED does not turn off even though slip paper is removed Cause Solution and reference There are small pieces of paper in the... -

Page 115: The Customer Display Does Not Appear

The cash drawer is not connected. Check the connection between the cash drawer and the cable. The cash drawer specifications and Use the TM-H6000VI Utility to check operation. drawer port specifications are not At this time, check the pin number of the signal. -

Page 116: Auto Cutter Error

Chapter 6 Troubleshooting Auto cutter error Open the roll paper cover, and check for foreign material. Then, perform error recovery from the system you are using. If the roll paper cover will not open, or if the same error occurs even after performing error recovery from the system, use the following procedure to return the cutter blade to its original position, and then perform error recovery. - Page 117 Chapter 6 Troubleshooting Use an object with a pointed tip such as a ballpoint pen or tweezers to turn the knob (a) of the autocutter blade in the direction of the arrow until you see a pin (b) in the opening of the frame, as shown in illustration below.

- Page 118 Chapter 6 Troubleshooting Pull out some paper, and close the roll paper cover. Tear off the paper with the manual cutter.

-

Page 119: Paper Jam

Chapter 6 Troubleshooting Paper jam Roll paper is jammed Do not touch the thermal head, because it can be very hot after printing. Let it cool before you remove the jammed paper. CAUTION Open the roll paper cover. Remove the jammed paper. -

Page 120: Slip Paper Is Jammed

Chapter 6 Troubleshooting Slip paper is jammed Open the front cover. Open the front carriage unit using the lever on the right side of the front carriage unit. When using an endorsement printer, also open the receipt unit. - Page 121 Chapter 6 Troubleshooting Remove the jammed paper. Close the front carriage unit using the lever. When using an endorsement printer, also close the receipt unit. Close the front cover. Then, perform error recovery from the system you are using.

-

Page 122: Roll Paper Cover Will Not Open

Chapter 6 Troubleshooting Roll paper cover will not open When the roll paper cover is locked and will not open, follow the steps below to return the autocutter blade to the normal position to unlock the roll paper cover. Open the receipt unit. Use an object with a pointed tip such as a ballpoint pen or tweezers to turn the knob (a) of the autocutter blade in the direction of the arrow until you see a pin (b) in the opening of the frame, as shown in illustration below. -

Page 123: Printing Stop By Cover Open

Chapter 6 Troubleshooting Printing stop by cover open Pull out some paper, and close the roll paper cover. Tear off the paper with the manual cutter. Perform error recovery from the system you are using. Do not open the covers during printing or autocutting. -

Page 124: Printing From The Computer Is Disabled/Printing Was Suddenly Stopped

Chapter 6 Troubleshooting Printing from the computer is disabled/Printing was suddenly stopped Printer is offline Remove the cause of going offline. "Online and Offline" on page Reconnect the printer and the computer Check the cable connection. Check whether the power cable and/or interface cables are properly connected. Reconnect all devices. -

Page 125: Power Does Not Turn On

Chapter 6 Troubleshooting Power does not turn on Check whether the power cable and AC adapter are properly connected to the printer and power outlet. -

Page 126: Replacement Of The Tm-H6000V

Chapter 7 Replacement of the TM-H6000V Replacement of the TM-H6000V The TM-H6000VI is designed so that it can smoothly replace the TM-H6000V. This chapter describes precautions for the replacement. TM-H6000VI TM-H6000V Receipt print speed 500 mm/s {19.69 in/s} 350 mm/s {13.78 in/s}... -

Page 127: Compatibility

The TM-H6000V receive buffer can be set to 4 KB or 45 bytes in Software Setting Mode or with DIP switch 1-2. The TM-H6000VI receive buffer is fixed at 4 KB. The conditions for a full buffer are the same as when the... -

Page 128: Memory Capacity

Chapter 7 Replacement of the TM-H6000V Memory Capacity The sizes of the download buffer and NV graphics data of the TM-H6000VI are the same as those of the TM-H6000V. Electrical Characteristics The operating voltage of the TM-H6000VI is DC 24 V±7%, the same as the TM-H6000V. The current consumption differs, depending on the print duty. -

Page 129: Overall Dimensions

Chapter 7 Replacement of the TM-H6000V Overall Dimensions TM-H6000VI TM-H6000V W:186 × D:278 × H:181 mm Approximately. 4.4kg W:186 × D:278 × H:181 mm Approximately. 4.4kg {W:7.32 in × D:10.94 in × H:7.13 in Approximately. 9.70 lb} {W:7.32 in × D:10.94 in × H:7.13 in Approximately. 9.70 lb}... -

Page 130: Additional Functions And Functional Improvements

SimpleAP Function The TM-H6000VI comes with a mode (SimpleAP) that allows the printer to connect directly when using an optional wireless LAN unit without having to use a wireless LAN access point. The wireless LAN setting can be set using Web Config other than the TM-H6000VI Utility. -

Page 131: Software Settings

Chapter 7 Replacement of the TM-H6000V Software Settings For the TM-H6000VI, the following software setting functions are added. • Print Speed • Font Priority • Interface switch waiting time • Printer Model TM-Intelligent function The TM-H6000VI supports the following TM-Intelligent function. -

Page 132: Appendix

Appendix Appendix Product Specifications Printing Receipt Thermal line method Slip/Endorsement 9-pin serial impact dot matrix Cutting method for receipt Partial cut (cutting with one point in left edge left uncut) MICR reader Permanent magnet Paper Receipt 79.5±0.5 × 83 mm {3.1±0.02 × 3.3 in.} dimensions Slip 68 to 230 ×... - Page 133 Appendix Two-dimensional symbol/ PDF417, MaxiCode, Data Matrix, Aztec Code, GS1 DataBar, Composite symbol printing Composite Symbology Inked ribbon Slip ERC-32 Endorsement ERC-43 Supplied voltage DC 24 V±7% Current consumption Mean: Approximately. 1.8 A AC power consumption Operating: Approximately. 26.6 W (100 to 230 V, 50 to 60 Hz) Standby: Approximately.

-

Page 134: Printing Specifications

Appendix Printing Specifications Slip printing Printing method Serial impact dot matrix Head wire configuration 9-pin vertical line, wire pitch approximately 0.353 mm {0.014 in} Printing direction Bidirectional, minimum distance printing Printing speed Front Approximately. 5.7 lps (printing 40 columns per line with 17.8 cpi) Endorsement Approximately. - Page 135 Appendix Receipt printing Printing method Thermal line printing Dot density 180 × 180 dpi Printing direction Unidirectional with friction feed Maximum print speed * 500 mm/s {19.69 in/s} (at DC 24 V, 25 °C, Print density 100%) Printing width 72.0 mm {2.83 in}, 512 dots Characters per line Font A (initial setting): 42 (46 in 46-column mode) Font B: 56...

-

Page 136: Character Specifications

International characters: 14 character types GB18030-2022*: 28,806 (Lv.2) (for Simplified Chinese characters model) Big5: 13,502 (for Traditional Chinese characters model) * GB2312 can be changed using the TM-H6000VI Utility. For details on TM-H6000VI Utility, refer to TM-H6000VI Utility User's Manual. Character structure Font A 5 ×... - Page 137 Appendix Character size Font A 1.41 × 3.39 mm {0.06 x 0.13 in} (W x H) Font B 0.99 × 2.40 mm {0.04 x 0.09 in} Font C 1.27 × 2.82 mm {0.05 x 0.11 in} Multi-byte character font 3.39 × 3.39 mm {0.13 x 0.13 in} •...

-

Page 138: Paper Specifications

Appendix Paper Specifications Slip printing Types Normal paper, pressure sensitive paper, carbon copy paper Form Slip paper Size (W × L) 68 to 230 mm × 68 to 297 mm {2.68 to 9.06 in × 2.68 to 11.69 in} The minimum size is 68 × 152 mm {2.68 × 5.98 in}. Thickness Normal paper (single-ply) 0.09 to 0.22 mm {0.0035 to 0.0087 in}... - Page 139 Appendix • Choose slip paper carefully when using slip paper with glued area, since printing, paper feeding, and insertion are affected by gluing conditions (e.g. quality, method, and length of glue) and glue location. Be especially careful when slip paper is wide and has the glue on the left edge, since drifting may occur.

- Page 140 Appendix Receipt printing Type Thermal paper Form Roll paper Size Roll paper diameter 83 mm {3.27 in} maximum Roll paper spool Inside: 12 mm {0.47 in}, Outside: 18 mm {0.71 in} Roll paper core width Same as the roll paper width, or smaller than the paper width by 1 mm {0.04 in} or less.

-

Page 141: Printable Area

Appendix • The initial setting is 100% print density. • If setting the speed to 500 mm/s {19.69 in/s}, use a customized value to set the print density to the recommended setting. • When the print density setting is too dark, the print speed tends to drop. If the print density is 115% or higher, and the room temperature is 15°C {59°F} or lower, the speed will be 240 mm/s {9.45 in/s} or slower. - Page 142 Appendix Slip (endorsement) printing Top margin 47.8 16.2 Paper feeding Bottom margin direction [units: mm (All the numeric values are typical.)] Slip (validation) printing 85.4 Bottom margin [units: mm (All the numeric values are typical.)] Receipt printing Maximum printable area 79.5±0.5 72±0.2 mm {2.83±0.008} Left margin...

-

Page 143: Printing And Cutting Positions

Appendix Printing and Cutting Positions Manual-cutter position Approximately. 24 mm {0.94 in} Approximately. Autocutter blade position 10 mm {0.39 in} Paper feed direction Center of the print dotline [units: mm (All the numeric values are typical.)] • The values above may vary slightly as a result of paper slack or variations in the paper. •... -

Page 144: Notes On Using The Endorsement Printer

Appendix Notes on using the endorsement printer You can use an endorsement printer to perform MICR reading and endorsement printing without turning over the check. For this reason, be careful of the following points regarding the endorsement printer when developing an application. •... - Page 145 Appendix Area of MICR Recognition 46.0 Area where recognition is impossible Inserting direction [units: mm (All the numeric values are typical.)] Area Specified for Endorsement Area specified for endorsement 38.1 Sample Endorsement [units: mm (All the numeric values are typical.)] In order to assuredly print on the area specified for endorsement (within 38.1 mm {1.5 in} from the edge), use settings that provide approximately 3 mm {0.12 in} of space at the bottom of the print specified area.

- Page 146 Appendix Notes on using the MICR reader • For MICR reading, the minimum length of paper is 120 mm {4.72 in}. • The check paper must be flat and without curls, folds (especially curls or folds at the top edges), curves, or wrinkles.

-

Page 147: Barcode/ Two-Dimensional Symbol/Composite Symbol

Appendix Barcode/ Two-dimensional symbol/composite symbol Barcode/two-dimensional symbol Print Direction Barcode/two-dimensional symbol print direction and name are as follows. Fence Barcode Ladder Barcode Paper feed direction... -

Page 148: Notes On Using The Multi-Tone Graphics Printing

Appendix Notes on using the multi-tone graphics printing Multi-tone graphics printing is available on receipts. • Multi-tone printing is not supported in Page mode. • Voids (white spaces) may appear depending on the paper type (uneven application of chromogenic coating). •... -

Page 149: Electrical Characteristics

Appendix Electrical Characteristics Supply voltage DC 24 V±7% Current consumption Standby Mean: Approximately. 0.1 A (when using the PS-190 Operating Slip printing Mean: Approximately. 1.7 A at 24V) Receipt printing Mean: Approximately. 1.8 A Note: When print ratio is approximately 18% •... -

Page 150: Reliability

Appendix Reliability Life Slip printer section/ N u m b e r o f c ar r i a g e 12,000,000 times for each section Endorsement printer driving times section Number of paper feeds Total for the sections: 27,000,000 lines Print head 200 million characters (when printing with Font B only) -

Page 151: Environmental Conditions

Approximately. 55 dB (bystander position) (including autocutting operation) (operating, receipt printer section) Note: The values above are measured in the Epson evaluation condition. Acoustic noise differs depending on the paper used, printing contents, and the setting values, such as print speed or print density. Air pressure 726 hPa (Approximately. -

Page 152: External Dimensions And Mass

Appendix External Dimensions and Mass The external dimensions and mass of the standard model (with MICR reader and endorsement printer) • Height: Approximately 181 mm {7.13 in} • Width: Approximately 186 mm {7.32 in} • Depth: Approximately 278 mm {10.94 in} (excluding the connector cover) •... -

Page 153: Specifications Of Interfaces And Connectors

(with full-speed connection) USB bulk IN (TM) 64 bytes USB device class USB vendor-defined class. USB descriptor USB vendor-defined class Vendor ID 04b8h Product ID 0202h String Descriptor Manufacturer EPSON Product TM-H6000VI Serial number Character string based on the product serial number... -

Page 154: Network Interface

Appendix Network Interface For both Ethernet interface and Wi-Fi interface Support protocols Protocols Usage IP, ARP, ICMP, UDP, TCP Basic communication protocols LP, LPR, TCP Socket Port Printing protocols HTTP/HTTPS Used in ePOS-Print and Web Config SNMP, ENPC Used in setting and monitoring DHCP, APIPA Used in automatic setting for the IP address and so on Network parameters... - Page 155 The following setting values are applied when the SimpleAP function is operating. Parameter Setting value SSID DIRECT-TM-H6000VI-"serial number" Security WPA2-PSK Passphrase See "Default Password for "Default Password for Setup / Default Passphrase for SimpleAP"...

-

Page 156: Default Password For Setup / Default Passphrase For Simpleap

To improve security, it is recommended to change the administrator password from the default password. The password can be changed from [Advanced Settings] - [Product Security] - [Change Administrator Password] in Web Config. It can also be changed using TM-H6000VI Utility. -

Page 157: Rs-232 Serial Interface

Appendix RS-232 Serial Interface Interface board specifications (RS-232-compliant) Item Specifications Data transfer method Serial Synchronization Asynchronous Handshake Select one of the following with DIP switch 1-3: • DTR/DSR • XON/XOFF Signal level MARK -3 to -15V logic "1"/OFF SPACE +3 to +15V logic "0"/ON Bit length Select one of the following with DIP switch 1-4: •... - Page 158 Appendix Pin no. Signal name Signal direction Function Input This signal indicates whether the host computer can receive data. • SPACE status Indicates that the host computer can receive data. • MARK status Indicates that the host computer cannot receive data. When DTR/DSR control is selected, the printer transmits data after confirming this signal (except if transmitted using some ESC/POS commands).

-

Page 159: Nfc Tag

Appendix XON/XOFF When XON/XOFF control is selected, the printer transmits the XON or XOFF signals as follows. The transmission timing of XON/XOFF differs, depending on the setting of DIP switch 2-1. DIP switch 2-1 Signal Printer status 1 (ON) 0 (OFF) 1) When the printer goes online after turning on the power (or reset using Transmit Transmit... -

Page 160: Bluetooth Low Energy Technology Advertising

If the power is turned on after this device is connected to a Bluetooth adapter, then Bluetooth Low Energy Tech- nology Advertising Packets are transferred. By default, the TM-H6000VI transmits the packet according to the iBeacon Format from Apple. You can also change the data that is transmitted by following the steps in "Changing the Bluetooth Low Energy Technology... -

Page 161: Changing The Bluetooth Low Energy Technology Advertising Packet

Appendix Bluetooth Low Energy Technology Advertising Packet Format In the TM-H6000VI, the iBeacon format is used by default for the Bluetooth low energy technology Advertising Packet. The UUID for the TM-H6000VI is "fac1ba2f-61a2-4d83-9a8c-60087c232569". The user can edit the following specifications in the iBeacon format: UUID, Major number, Minor number, and Measured Power. - Page 162 Appendix The ID for the authentication is "epson". For the default password, refer to "Default Password for Setup / Default Passphrase for SimpleAP" on page 156. Escape processing for configuration scripts When reading/writing a configuration script for a printer, the strings (content of the configuration script) being transmitted and received uses the following escape processing.

- Page 163 Appendix Type Description status Acquires information for the Bluetooth adapter. Response Response Header Content-Type: application/json; charset=utf-8 Access-Control-Allow-Origin: * Access-Control-Allow-Methods: POST, GET, OPTIONS, HEADER Access-Control-Allow-Headers: Content-Type, Content-Length, Authorization X-Content-Type-Options: nosniff X-XSS-protection: 1; mode=block X-Frame-Options: deny Content-Security-Policy: default-src 'none' WWW-Authenticate: Digest realm="<IPaddr>", nonce="xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx", qop="auth" Response Function GET Parameter...

- Page 164 Appendix GET Response Body (Type =Other than the status) Response Status Response Body 200 OK "message": "Success" "detail": null "description" : <Encoded string for the configuration script> 404 Not Found "message": "Requested file not found" "detail": null "description" : null 400 Bad Request "message": "Invalid Parameter"...

- Page 165 Appendix Writing the configuration script to the printer You can save a configuration script to the printer using the HTTP POST method. You can save the configuration script to volatile or non-volatile memory. When changing using a low frequency less than once an hour, you can save to non-volatile memory; however, when changing at a higher frequency, you need to save to volatile memory.

- Page 166 Appendix Function POST Parameters Results Response Updates the configuration Update successful 200 OK script in non-volatile "type" : "static", memory "description": "<The It has following header: string for the X-RateLimit-Limit: 1 configuration script that X-RateLimit-Remaining: 0 performed escape X-RateLimit-Reset: xx processing>"...

- Page 167 Appendix POST Response Body Response Status Body 200 OK "message": "Success", "detail": null, "description" : < The string for the configuration script that performed escape processing > 400 Bad Request "message": "Invalid Parameter", "detail": "***", (see Table 400 Bad Request Details) "description"...

- Page 168 Appendix Case Body No Type specified Or an invalid parameter has been "message": " Invalid Parameter ", specified "detail": "A parameter ‘type’ or ‘description’ is not specified", "description" : null When detecting a string with invalid escape processing "message": " Invalid Parameter ", "detail": "Invalid parameter is found", "description": null 500 Internal Server Error Details...

- Page 169 Format: cmd 0x08 0x0005 n6 n5 n4 n3 n2 n1 Function: Specify a BD Address. Specify a value in Little Endian. As a Random Static Address is used in TM-H6000VI, bit7 and bit6 for n1 need to be set to 1. Bluetooth low energy technology Advertising parameter specifications Format: cmd 0x08 0x0006 aL aH bL bH c d e f1 f2 f3 f4 f5 f6 g h Function: Sets a variety of parameters for the Advertising packet.

- Page 170 Appendix Bluetooth low energy technology Advertising Packet specifications Format: cmd 0x08 0x0008 d1 d2 … d32 Function: Sets the Data for the Bluetooth low energy technology Advertising packet. Specify all from d1 to d32. If these are not necessary, specify 00 for each one. Definition Length Default (iBeacon)

- Page 171 IP3: 64h IP4: c8h $MODEL_NO 2 bytes Can be used for 0010h is used for the TM-H6000V. differentiating printers 0028h is used for the TM-H6000VI. 0000h: No use 0001h: Reserved 0010h: TM-H6000V 0028h: TM-H6000VI $MACn 1 byte Value for #n in the MAC Available range: address.

-

Page 172: Character Code Tables

Appendix Character Code Tables See the Character Code Tables for TM Printers that can be accessed from the following URL: https://download4.epson.biz/sec_pubs/pos/reference_en/...